Paraffin scraping and collar detecting device of oil pumping rod

A detection device and sucker rod technology, which is applied in the direction of measurement, cleaning equipment, wellbore/well parts, etc., can solve the problems of inability to remove wax, low removal efficiency, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

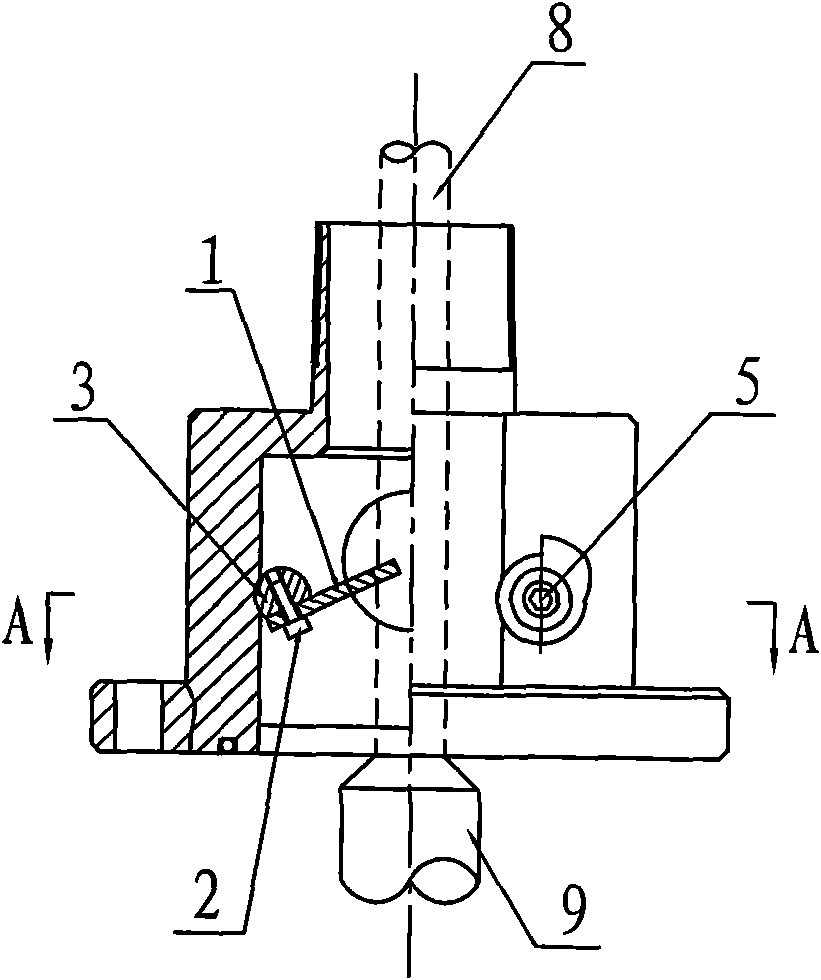

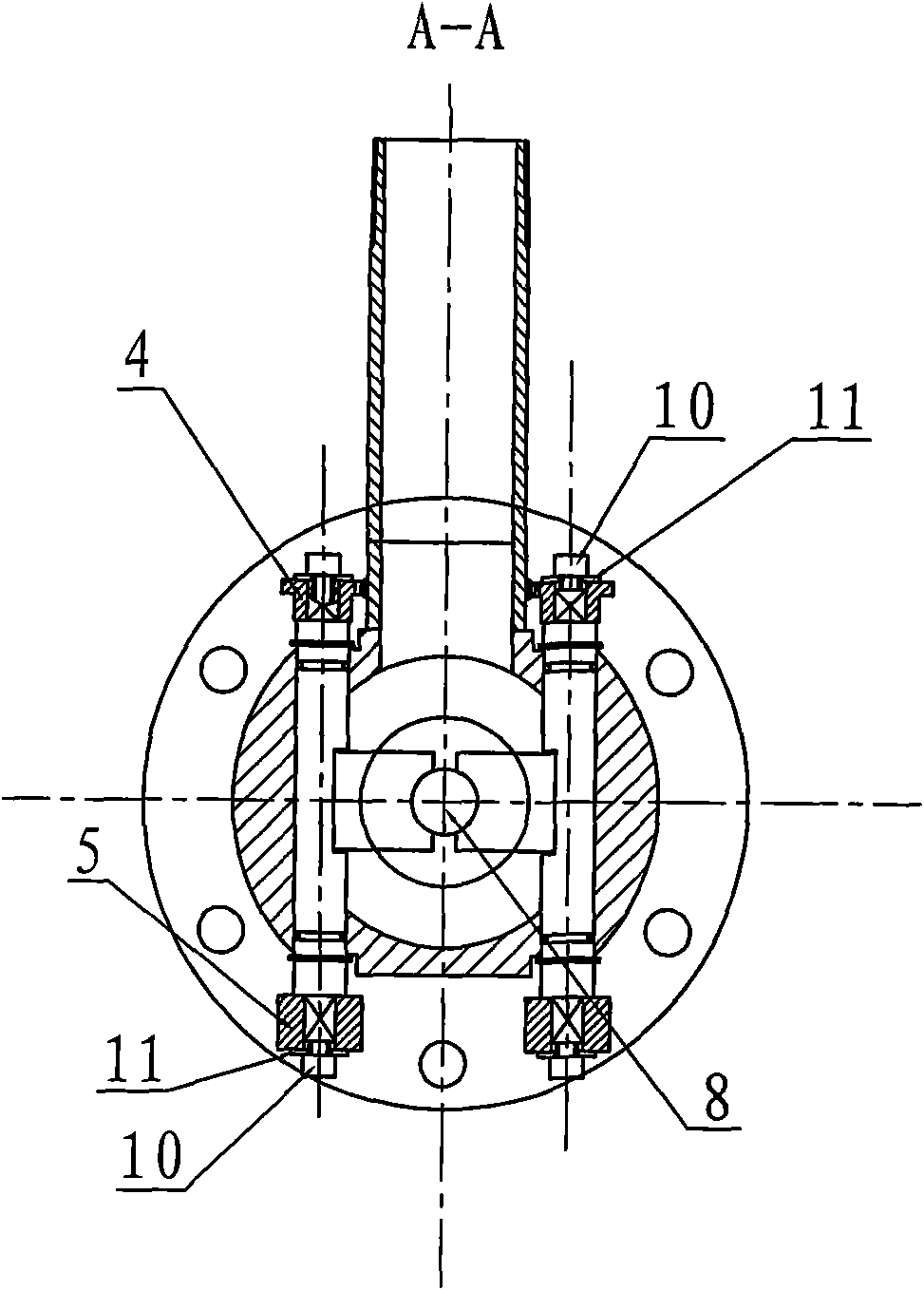

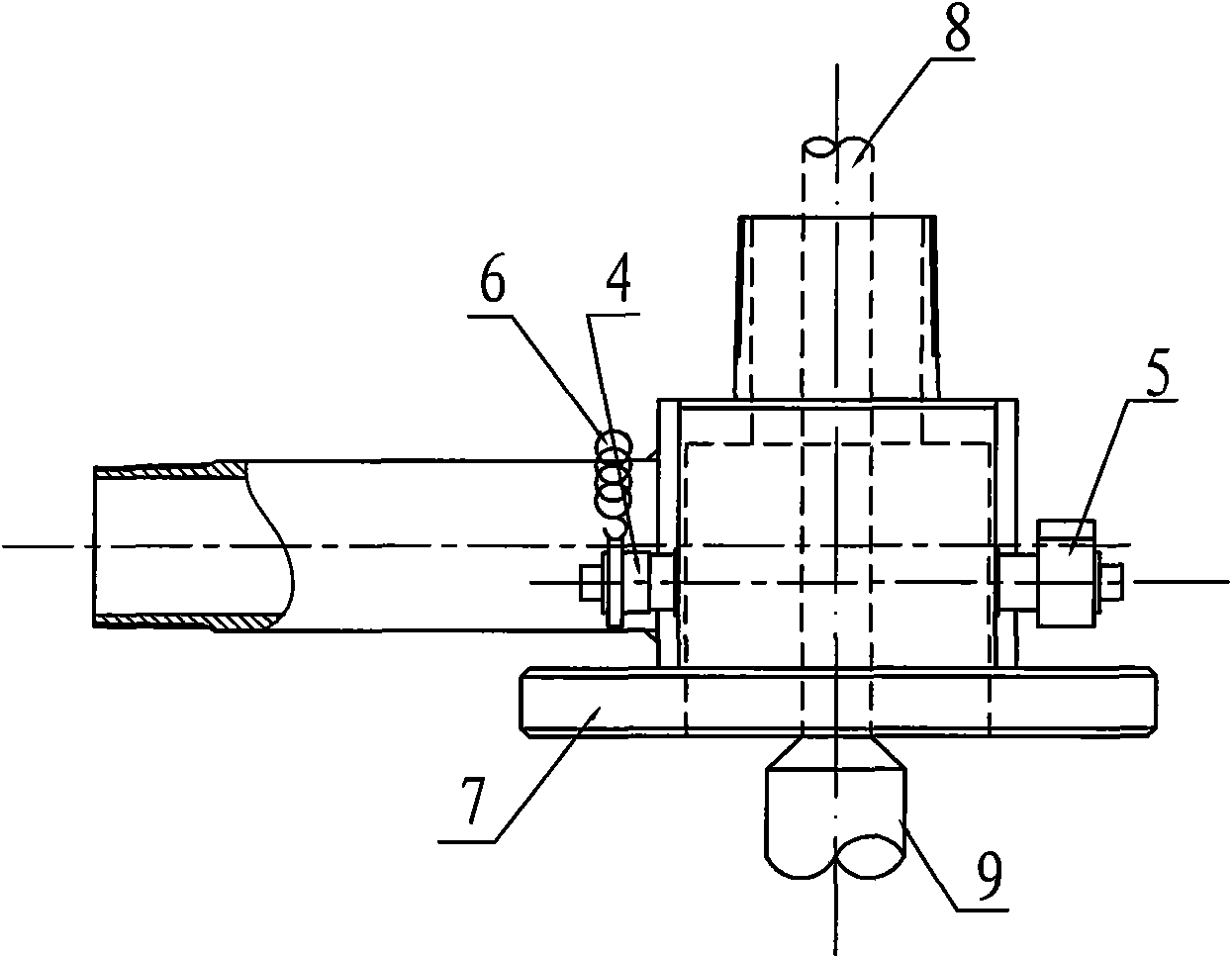

[0015] The wax scraping and coupling detection device for the sucker rod, such as Figure 1 to Figure 3 As shown, it includes a metal scraper 1, a connecting screw 2, a rotating shaft 3, a tension wheel 4, a signal cam 5, a tension spring 6 and a connecting seat 7; the connecting seat 7 is a stepped structure, such as Figure 4 As shown, it includes a sheath 71, an executive sleeve 72 and a base 73, the central hole of the sheath 71 is coaxial with the central hole of the executive sleeve 72, and two sets of shafts for installing the rotating shaft 3 are arranged on the same height of the executive sleeve 72. Horizontal holes 74, two groups of horizontal holes 74 are distributed symmetrically with respect to the axis of the executive sleeve 72, the metal scraper 1 is fixedly installed on the rotating shaft 3 through the connecting screw 2, and the distance between the metal scraper 1 and the axis of the sucker rod 8 is normal. The angle between the metal scraper 1 and the suck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com