Cable wet butt joint electric submersible screw pump

A technology of submersible screw and screw pump, applied in the direction of rotary piston/oscillating piston pump combination, pump, circuit, etc., can solve the problems of shortening protector, motor service life, easy damage, oil and gas well overhaul, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

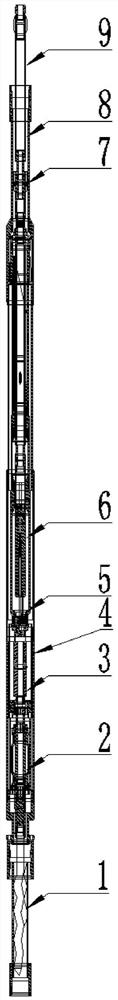

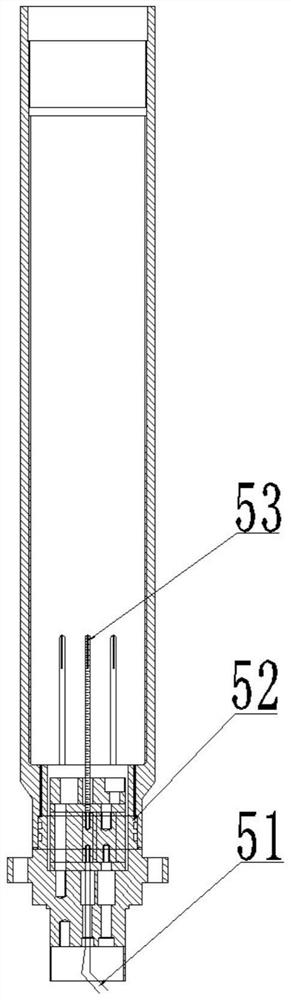

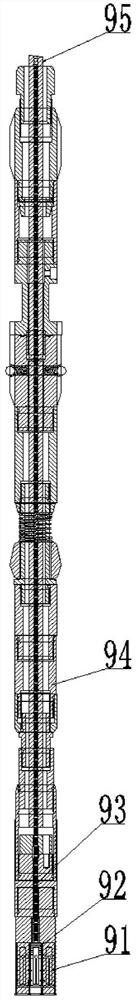

[0021] Such as Figure 1-5 As shown, a cable wet-butt electric submersible screw pump includes a screw pump 1, a shroud 4 is arranged above the screw pump 1, and protectors are arranged inside the shroud 4 sequentially from bottom to top 2. The motor 3 and the cable socket 5, a sealed chamber 6 is arranged above the cable socket 5, the cable socket 5 is electrically connected to the motor 3, and an oil pipe 8 is arranged above the shroud 4, so that The inside of the oil pipe 8 is provided with a cable 9 with a counterweight plug, and the outer side of the cable 9 with a counterweight plug is provided with a plug lock 7, and the cable 9 with a counterweight plug is connected from the oil pipe 8. The inside passes through and enters the inside of the sealed chamber 6, the cable 9 with a counterweight plug is inserted into the cable socket 5 and locked by the plug lock 7; it also includes a control system, the The motor 3 is electrically connected to the control system; the cabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com