Alitizing modified steel used for P110-grade oil sleeve and tubular product manufacturing method of alitizing modified P110-grade steel

A technology of surface aluminizing and manufacturing method, which is applied in the field of surface aluminizing modified P110 grade oil casing steel and its pipe manufacturing field, can solve the problems of decreased anti-corrosion performance of the pipe surface, long supply cycle, complicated process, etc. Low content, saving energy and cost, good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

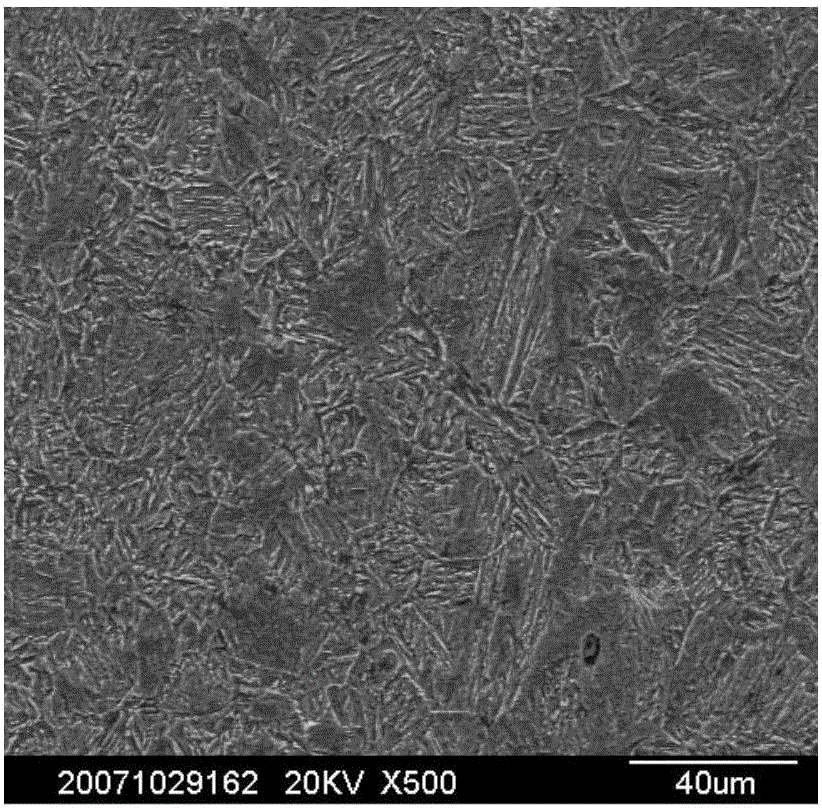

[0042] A surface aluminized modified P110 steel for oil casing, its chemical composition (weight percentage) is: 0.079% of C, 2.3% of Mn, 0.7% of Si, 0.0078% of P, 0.0017% of S, 1.1% Cr, 0.019% Ti, and the rest is Fe.

[0043] The method for manufacturing the above-mentioned surface aluminized modified P110 steel pipe for oil casing pipes, according to the percentage by weight, the above-mentioned components are smelted in a converter or an electric furnace, refined outside the refinery, and cast to obtain a tube blank, and the tube blank is heated to 1250°C by an annular heating furnace ;Pierce the heated tube billet through the piercing machine, and the temperature of the tube billet after piercing is 1220°C; then it is rolled through the continuous rolling mill, and the rolling start temperature of the continuous rolling mill is controlled to be 1180°C; then it is sized through the sizing mill , the starting temperature of the sizing unit is controlled to be 870°C; it is st...

Embodiment 2

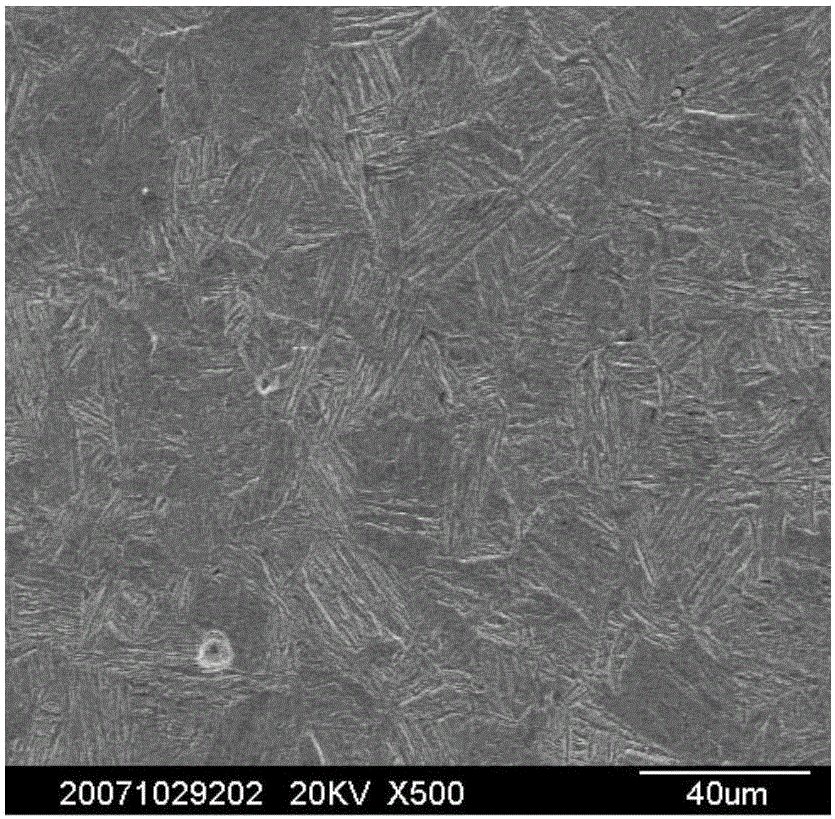

[0046]A surface aluminized modified P110 steel for oil casing, its chemical composition (weight percentage) is: 0.083% of C, 2.31% of Mn, 0.61% of Si, 0.0088% of P, 0.0024% of S, 1.1% Cr, 0.020% Ti, and the rest is Fe.

[0047] The manufacturing method of the above-mentioned surface aluminized modified P110 grade oil casing steel pipe, according to the weight percentage, the above-mentioned cost is smelted in a converter or an electric furnace, refined outside the refinery, and cast to obtain a tube blank, and the tube blank is heated to 1250°C by an annular heating furnace ;Pierce the heated tube billet through the piercing machine, and the temperature of the tube billet after piercing is 1200°C; then it is rolled through the continuous rolling mill, and the rolling start temperature of the continuous rolling mill is controlled to be 1150°C; then it is sized through the sizing mill , the starting temperature after controlling the sizing unit is 850°C; it is straightened by a ...

Embodiment 3

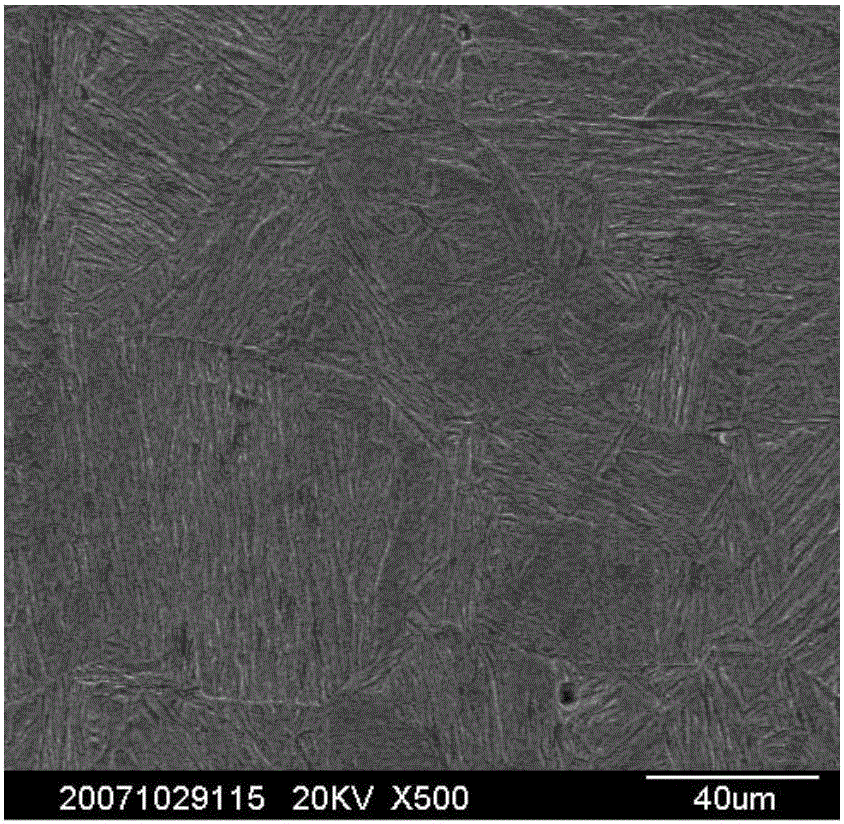

[0050] A surface aluminized modified P110 steel for oil casing, its chemical composition (weight percentage) is: 0.089% C, 2.31% Mn, 0.71% Si, 0.0078% P, 0.0028% S, 1.2% Cr, 0.020% Ti, and the rest is Fe.

[0051] The method for manufacturing the above-mentioned surface aluminized modified P110 steel pipe for oil and casing, according to the percentage by weight, the above-mentioned components are smelted in a converter or an electric furnace, refined outside the refinery, and cast to obtain a tube blank, and the tube blank is heated to 1250°C by an annular heating furnace ;Pierce the heated tube billet through the piercing machine, and the temperature of the tube billet after piercing is 1220°C; then it is rolled by the continuous rolling mill, and the rolling start temperature of the continuous rolling mill is controlled to be 1150°C; and then sized by the sizing mill , the starting temperature after controlling the sizing unit is 860°C; it is straightened by a straightening...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com