Infrared adjustment intelligent thermal insulation EVA film and preparation method thereof

An intelligent heat insulation and infrared technology, applied in adhesives, film/sheet adhesives, adhesive additives, etc., to achieve low light reflectivity, warm in winter and cool in summer, and high transmittance of visible light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

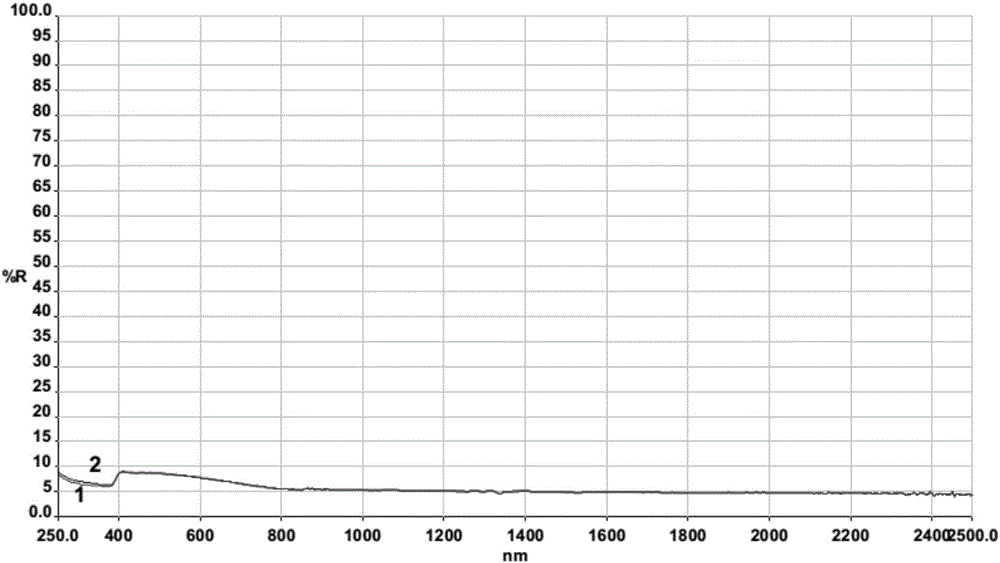

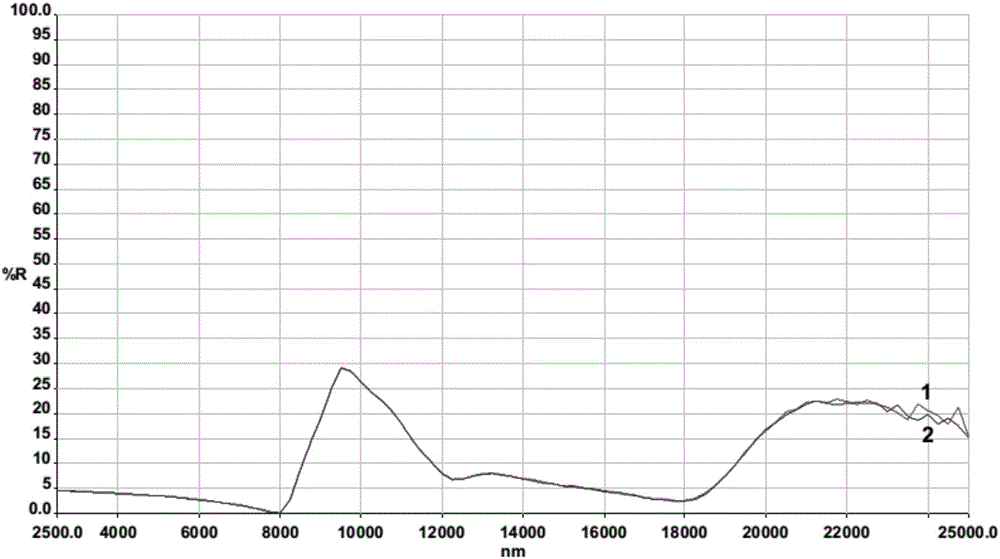

Image

Examples

Embodiment 1

[0034]This embodiment provides an infrared-adjustable intelligent heat-insulating EVA film and a method for preparing an infrared-regulated intelligent heat-insulating EVA film. The specific steps are as follows:

[0035] 60g modified powder (W doped with VO 2 , the amount of substance in W is VO 2 0.8% of the amount of substance, the particle diameter of modified powder is 30nm), 3g dispersant (EFKA-4310), 2g antioxidant (HostanoxP-EPQ) and 435gEVA micelle (KA-31) are mixed and added to Extrude and granulate in a twin-screw granulator to obtain a regulator (functional masterbatch). (In the conditioner, the quality of the modified powder accounts for 12%, the quality of the dispersant accounts for 0.6%, the quality of the antioxidant agent accounts for 0.4%, and the quality of the EVA micelle accounts for 87%.)

[0036] 40g of γ-methacryloxypropyltrimethoxysilane (coupling agent), 40g of 1,1-di-tert-butylperoxy-3,3,5-trimethylcyclohexane (crosslinking agent), 20g 2-hydroxy-...

Embodiment 2

[0041] This embodiment provides an infrared-adjustable intelligent heat-insulating EVA film and a method for preparing an infrared-regulated intelligent heat-insulating EVA film. The specific steps are as follows:

[0042] 50g modified powder (Mo doped VO 2 , the amount of Mo substance is VO 2 1.2% of the amount of substance, the particle diameter of modified powder is 30nm), 4g dispersant (EFKA-4310), 1g antioxidant (HostanoxP-EPQ) and 445gEVA micelle (KA-31) are mixed and added to Extrude and granulate in a twin-screw granulator to obtain a regulator (functional masterbatch). (In the conditioner, the quality of the modified powder accounts for 10%, the quality of the dispersant accounts for 0.8%, the quality of the antioxidant agent accounts for 0.2%, and the quality of the EVA micelle accounts for 89%.)

[0043] 60g γ-methacryloxypropyl triisopropoxysilane (coupling agent), 40g 1,1-di-tert-butyl peroxide-3,3,5-trimethylcyclohexane (crosslinking agent ), 15g1-[3-[3-(2H-be...

Embodiment 3

[0048] This embodiment provides an infrared-adjustable intelligent heat-insulating EVA film and a method for preparing an infrared-regulated intelligent heat-insulating EVA film. The specific steps are as follows:

[0049] 40g modified powder (W and Ce co-doped VO 2 , the amount of substance in W is VO 2 0.8% of the amount of matter, the amount of matter of Ce is VO 2 0.4% of the amount of substance, the particle diameter of modified powder is 30nm), 4g dispersant (EFKA-4310), 1g antioxidant (HostanoxP-EPQ) and 455gEVA micelle (KA-31) are mixed and added to Extrude and granulate in a twin-screw granulator to obtain a regulator (functional masterbatch). (In the regulator, the quality of the modified powder accounts for 8%, the quality of the dispersant accounts for 0.8%, the quality of the antioxidant agent accounts for 0.2%, and the quality of the EVA micelle accounts for 91%.)

[0050] 30g γ-glycidyl ether oxypropyltrimethoxysilane (coupling agent), 40g tert-butyl peroxyca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com