Novel halogen-free flame retardant composite material and preparation method thereof

A flame retardant composite material and composite material technology are applied in the field of new halogen-free flame retardant composite materials and their preparation, which can solve the problems of non-polarity and the like, and achieve the effects of good adhesion, good impact strength and good low temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A preparation method of a novel halogen-free flame retardant composite material, comprising the following steps:

[0039] (1) According to the weight percentage, 54% PP, 10% TPU, 20% aluminum hypophosphite, 10% flame retardant synergist, 5% EDPM-g-MAH and 1% coupling agent are mixed and stirred uniformly to obtain Mixture; wherein, the flame retardant synergist is a compound flame retardant of MCA and zinc borate, wherein the mass ratio of MCA and zinc borate is 1:1; the coupling agent is KH560 silane coupling agent.

[0040] (2) the uniformly stirred mixture in step (1) is fed into the extruder, the reaction time of the mixture in the extruder is 3-5min, and the reaction temperature is 180-190° C. to obtain a mixture in a molten state;

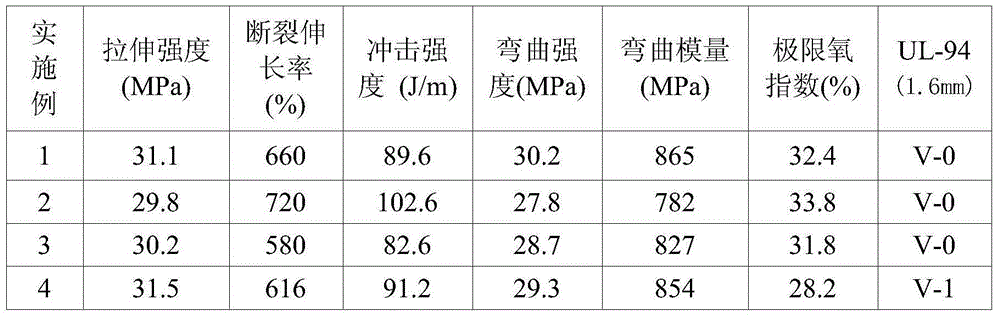

[0041] (3) The mixture in the molten state is extruded into a strip through an extruder, and then subjected to a dicing operation after being cooled under water to obtain PP / TPU composite pellets. The product performance is shown in T...

Embodiment 2

[0043] A preparation method of a novel halogen-free flame retardant composite material, comprising the following steps:

[0044] (1) According to the weight percentage, 44% PP, 20% TPU, 20% aluminum hypophosphite, 10% flame retardant synergist, 5% EDPM-g-MAH and 1% coupling agent are mixed and stirred uniformly to obtain Mixture; wherein, the flame retardant synergist is a compound flame retardant whose mass ratio of MCA and zinc borate is 1:1; the coupling agent is KH560 silane coupling agent.

[0045] (2) the mixture that is uniformly stirred in step (1) is sent into the extruder, the reaction time of the mixture in the extruder is 3-5min, and the reaction temperature is 180-190 ° C, to obtain the mixture in a molten state;

[0046] (3) The mixture in the molten state is extruded into a strip through an extruder, and then subjected to a dicing operation after being cooled under water to obtain PP / TPU composite pellets. The product performance is shown in Table 1.

Embodiment 3

[0048] A preparation method of a novel halogen-free flame retardant composite material, comprising the following steps:

[0049] According to weight percentage, 54% PP, 10% TPU, 20% aluminum hypophosphite, 10% flame retardant synergist, 5% POE-g-MAH, 1% coupling agent are mixed and stirred uniformly to obtain a mixture. Wherein, the flame retardant synergist is a compound flame retardant whose mass ratio of MCA and zinc borate is 1:1; the coupling agent is KH560 silane coupling agent.

[0050] Others are the same as in Example 1. The product properties are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com