AC Excited Track Eddy Current Brake and Its Braking Method

A technology of eddy current brake and AC excitation, which is applied in the direction of brake components interacting with the track, asynchronous inductive clutch/brake, railway braking system, etc. reduce the problem, achieve the effect of reducing temperature rise, prolonging life, and improving braking force output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

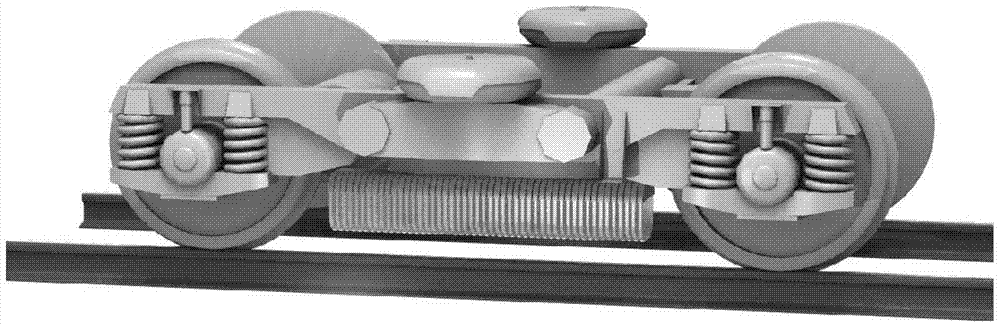

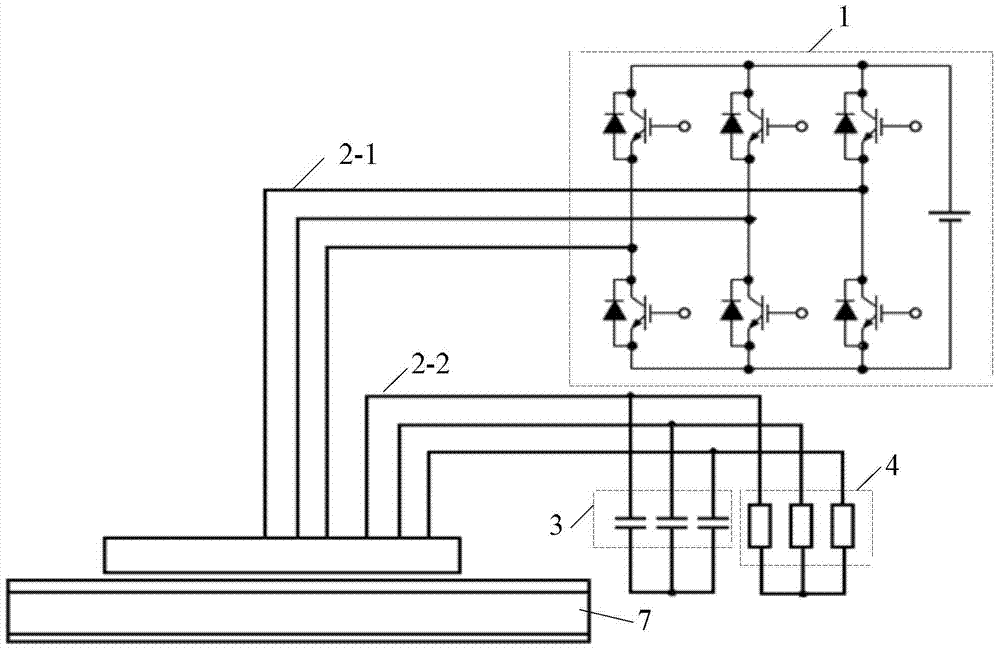

[0032] Specific implementation mode one: refer to figure 1 and Figure 4 Specifically illustrate this embodiment, the AC excitation rail eddy current brake described in this embodiment, it comprises eddy current braking unit, excitation control inverter 1, multi-phase rectifier 6 and excitation capacitor bank 3,

[0033] The eddy current braking unit includes a primary iron core, a primary control winding 2-1 and a primary power winding 2-2,

[0034] Slots are made on the side of the primary core facing the air gap perpendicular to the direction of movement, and two sets of ring-shaped multi-phase symmetrical windings are embedded in the slots, which are respectively the primary control winding 2-1 and the primary power winding 2-2,

[0035]The output end of the primary power winding 2-2 is connected to the excitation capacitor bank 3 in parallel, the output end of the primary power winding 2-2 is connected to the AC input end of the multi-phase rectifier 6, and the DC outpu...

specific Embodiment approach 2

[0039] Embodiment 2: This embodiment further explains the AC excitation track eddy current brake described in Embodiment 1. In this embodiment, the multi-phase rectifier 6 is an uncontrollable rectifier or a controllable rectifier.

specific Embodiment approach 3

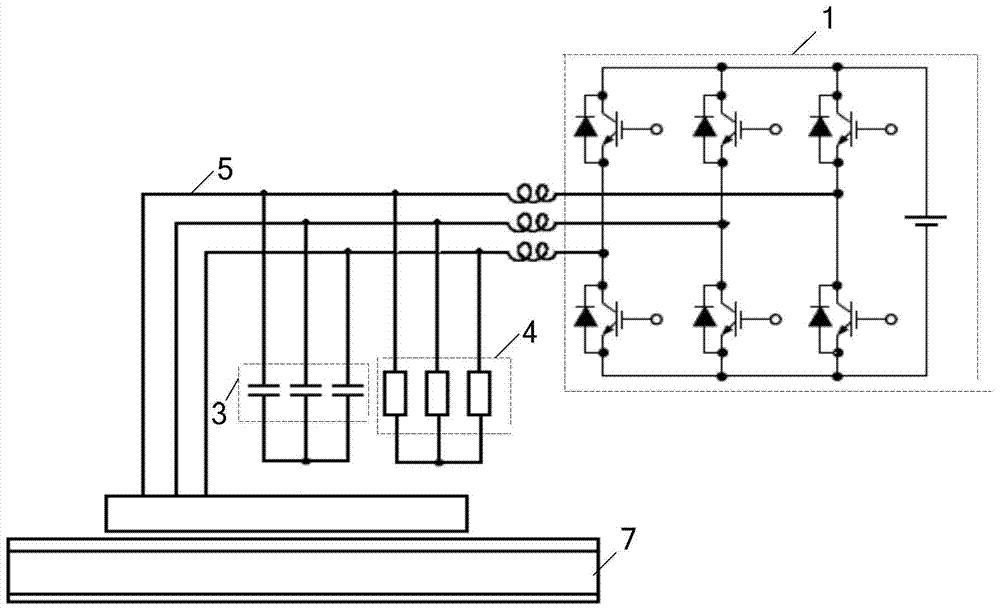

[0040] Specific implementation mode three: refer to figure 2 Specifically illustrate this embodiment, the AC excitation rail eddy current brake described in this embodiment, it comprises eddy current braking unit, excitation control inverter 1, energy absorbing resistor group 4 and excitation capacitor group 3,

[0041] The eddy current braking unit includes a primary iron core, a primary control winding 2-1 and a primary power winding 2-2,

[0042] Slots are made on the side of the primary core facing the air gap perpendicular to the direction of movement, and two sets of ring-shaped multi-phase symmetrical windings are embedded in the slots, which are respectively the primary control winding 2-1 and the primary power winding 2-2,

[0043] The output end of the primary power winding 2-2 is simultaneously connected to the excitation capacitor group 3 and the energy absorbing resistor group 4 in parallel, and the AC output end of the excitation control inverter 1 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com