A method for treating oil residue produced in the dairy sewage treatment process

A technology of sewage treatment and treatment method, which is applied in the field of waste oil residue and oil treatment, can solve the problems of high transportation cost, high comprehensive cost, and containing sludge, and achieve the effect of saving chemical costs and transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

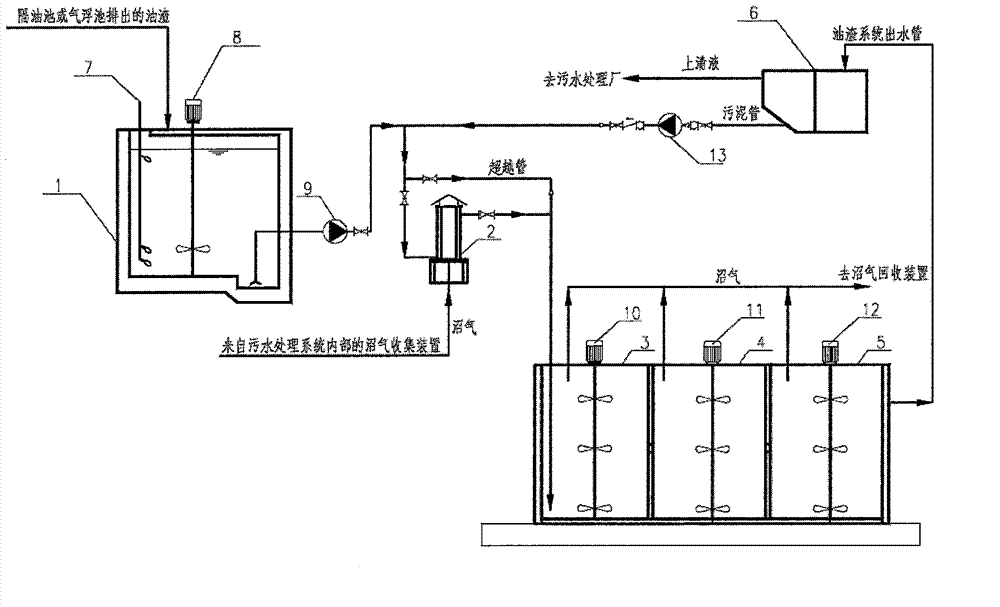

[0018] Below in conjunction with accompanying drawing, process flow of the present invention is described in detail

[0019] In the process of dairy waste water treatment, solid oil residue lighter than water will be produced in the grease trap or air flotation tank. The present invention treats this part of the oil residue and changes its state from a solidified state that is lighter than water to a solid state that can be mixed with water. In the liquid state of water miscibility, the COD of oil residue is greatly reduced to the acceptable range of the sewage treatment system, so that it can directly enter the sewage treatment system, and can be degraded and treated in the sewage plant. Proceed as follows:

[0020] (1) pretreatment, the oil residue separated from the grease trap or the air flotation tank is collected into the oil storage tank 1, and the mixer 8 is set in the oil storage tank 1, and mechanical stirring is performed to fully homogenize the oil residue; the oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com