Ultrahigh-power LED high-pole lamp

An LED high-pole light, ultra-high-power technology, applied in the loss prevention measures of lighting devices, cooling/heating devices of lighting devices, lighting and heating equipment, etc. User safety requirements, speeding up the speed of LED light decay, etc., to avoid attacking weak links, preventing slits and deformation, and taking high heat intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

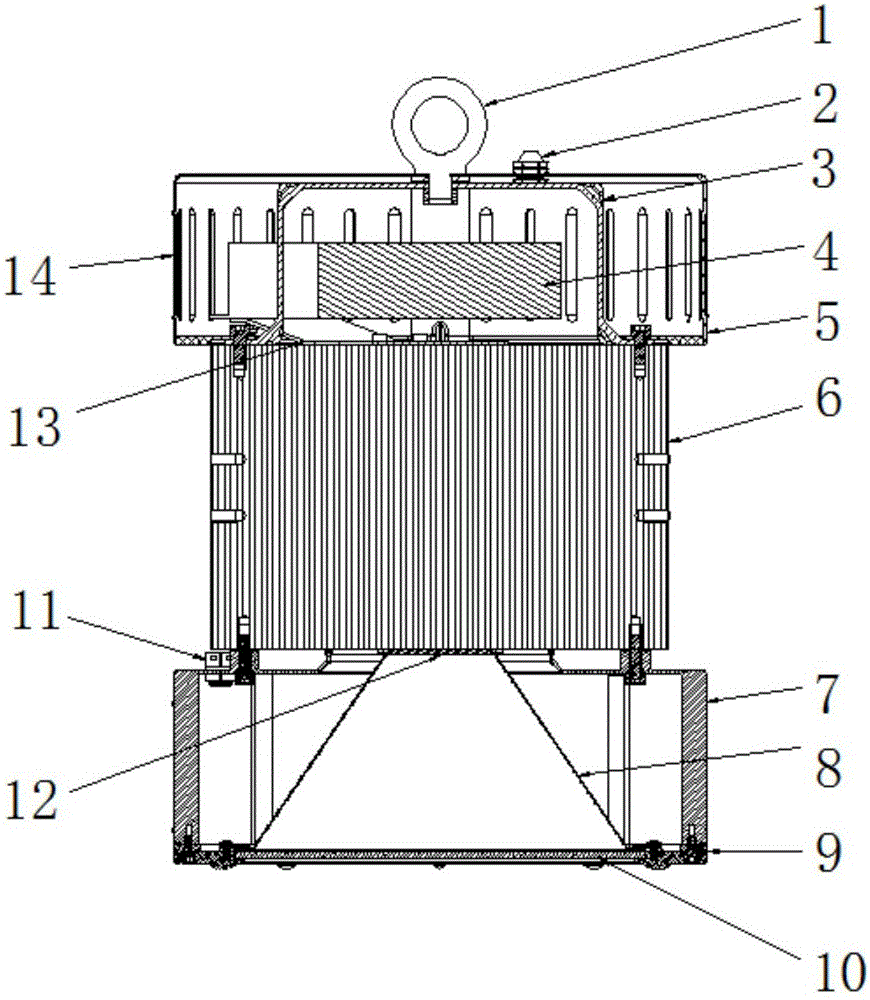

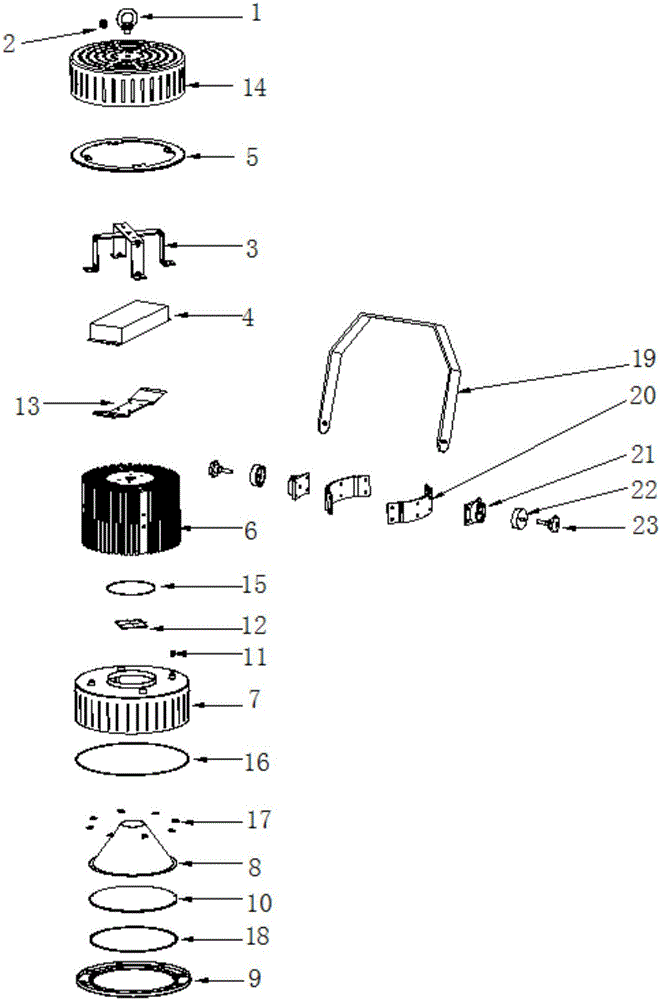

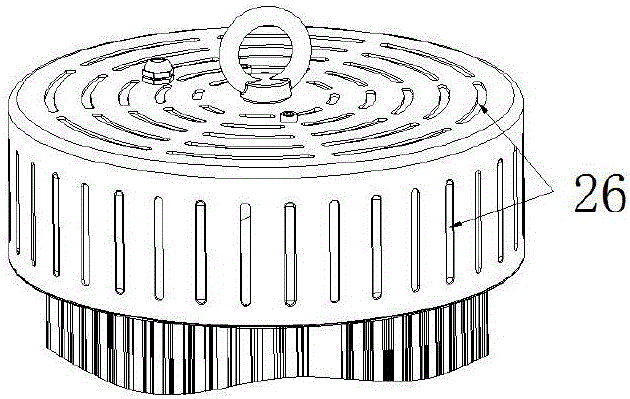

[0033] Such as figure 1 , figure 2 As shown, the shape of the entire high pole lamp is lantern-shaped, and the lamp body of the high pole lamp includes a hanging ring, a power supply cover assembly, a radiator assembly and a reflector assembly from top to bottom. The hanging ring 1 is arranged on the top of the lampshade assembly. The power supply cover assembly mainly includes a power supply cover 14 and a power supply 4 inside it. The top of the power supply cover 14 is provided with a waterproof power cord buckle 2, and the power supply cover shell fixing base 5 is pressed against the power supply cover 14 through the power supply cover shell fixing plate 3. The bottom of the power cover housing fixing plate 13 is fixedly connected with the top of the cooling assembly, and the power supply 4 is fixed inside the power supply cover through the power supply fixing seat 13. The radiator assembly mainly includes a radiator 6, which is respectively fixedly connected with the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com