A kind of green extraction process of lacquer wax

An extraction process and paint wax technology, applied in the field of natural product extraction process, can solve the problems of high cost, unsuitable for large-scale industrial extraction production and the like, and achieve the effects of low cost, low harm and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

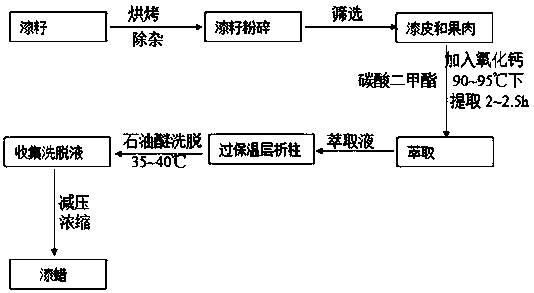

Method used

Image

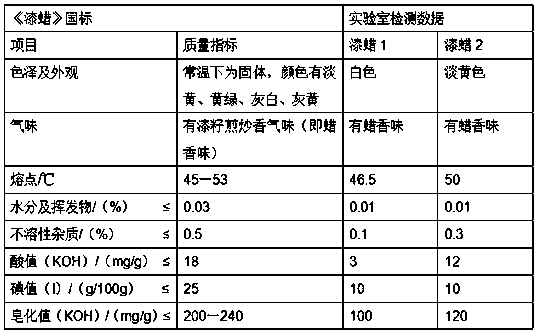

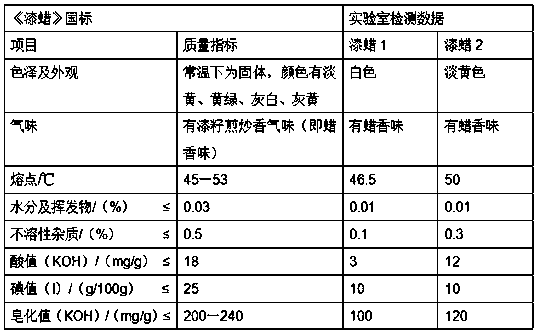

Examples

Embodiment 1

[0044] 1. Processing of raw materials: screen the collected lacquer seeds to get full particles, remove impurities in the granules, and dry the lacquer seeds from which impurities have been screened out at 50°C for about two hours; dry the dried lacquer seeds through Grinding to obtain the lacquer skin, pulp and lacquer seed core, separating the lacquer seed skin and pulp from the lacquer seed core with a fan, and pulverizing the separated lacquer skin and pulp respectively;

[0045]2. Weigh 40g of the crushed patent leather and pulp into a round bottom flask, add 200ml of dimethyl carbonate, then add 0.4g of calcium oxide powder, condense and reflux at 92~93°C for 2 hours, collect the extract, and repeat the extraction Step 1, combine the 2 extracted solutions to obtain about 386ml extract;

[0046] 3. Weigh 80g of 100~200 mesh pharmaceutical grade silica gel, and wet install it on the insulation chromatography column. The column temperature is controlled at 35~40℃, so that t...

Embodiment 2

[0050] 1. Processing of raw materials: Screen the collected lacquer seeds to get full granules, remove impurities in the granules, and dry the lacquer seeds from which impurities have been screened out at 30°C for about 2.5 hours; dry the dried lacquer seeds through Grinding to obtain the lacquer skin, pulp and lacquer seed core, separating the lacquer seed skin and pulp from the lacquer seed core with a fan, and pulverizing the separated lacquer skin and pulp respectively;

[0051] 2. Weigh 80g of the crushed patent leather and pulp into a round bottom flask, add 400ml of dimethyl carbonate, condense and reflux at 93~95℃ for 2.5 hours, add 0.5g of calcium oxide powder first during the condensing and reflux period, and take an interval of 1 hour Then add 0.4g of calcium oxide powder, collect the extract, repeat the extraction step once, and mix the two extracted solutions to obtain about 780ml of extract;

[0052] 3. Weigh 160g of 100~200 mesh pharmaceutical grade silica gel, ...

Embodiment 3

[0056] 1. Raw material processing: Bake the plucked lacquer seeds in a large oven at 50-60°C for 2 hours, then crush them with a large pulverizer, separate them with a fan, and get the skin and flesh for extraction ;

[0057] 2. Extraction: Put the obtained lacquer seed skin and pulp into an extraction tank with 800Kg as a tank, add 6 square meters of dimethyl carbonate extractant and 8Kg of small particles of calcium oxide, and condense and reflux at 93~95°C After 1 hour, collect the extract, repeat the above extraction step once, and combine the extract;

[0058] 3. Separation and purification: The extraction liquid passes through the column using simulated moving bed separation technology. The chromatographic columns in the simulated moving bed are all equipped with heat preservation, and the temperature is controlled at 45°C. Observe the separation situation, when the bottom of the chromatographic column is yellow, change the column for separation, circulate through the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com