Modified polypropylene composite material and preparation method thereof

A composite material and polypropylene technology, which is applied in the field of modified polypropylene composite material and its preparation, can solve the problems of poor compatibility between PP and inorganic materials, reduced processing fluidity, complicated preparation methods, etc., and achieves difficult adhesion and agglomeration. , The effect of improving heat resistance and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A modified polypropylene composite material is prepared by using polypropylene, styrene-butadiene thermoplastic elastomer, talcum powder and dicumyl peroxide at a mass ratio of 9:1:1:0.3 to prepare the modified polypropylene composite material.

[0037] A preparation method of modified polypropylene composite material, comprising the following steps:

[0038] Step 1, take the polypropylene of 90 weight parts, the styrene-butadiene thermoplastic elastomer of 10 weight parts, the talcum powder of 10 weight parts and the dicumyl peroxide of 3 weight parts;

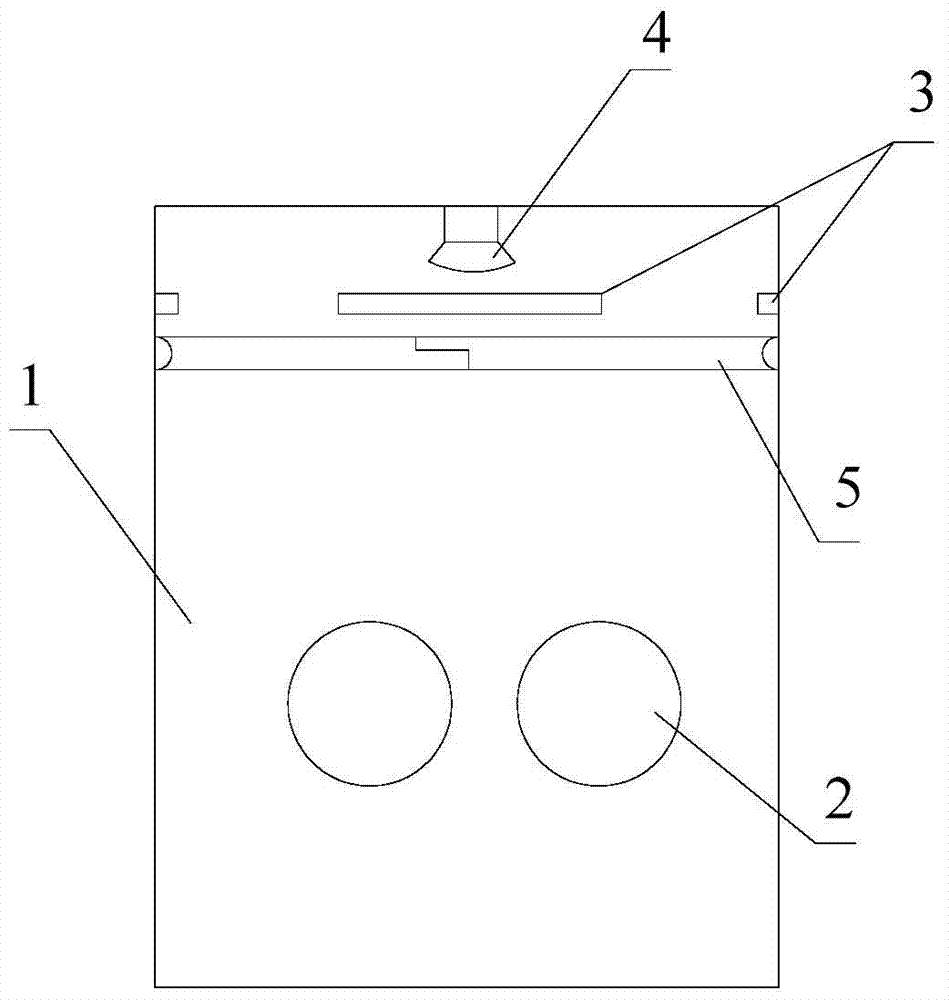

[0039] Step 2. Add the polypropylene, styrene-butadiene thermoplastic elastomer and talcum powder in the above parts by weight to the internal mixer and mix them for the first internal mixing. The time is 3 minutes, the temperature is 165 ° C, and the rotation speed is 50 rpm;

[0040] Step 3, adding 3 parts by weight of dicumyl peroxide for the second banburying, the time is 3min, the temperature is 150°C, and the rot...

Embodiment 2

[0043] A modified polypropylene composite material is prepared by using polypropylene, styrene-butadiene thermoplastic elastomer, talcum powder and dicumyl peroxide in a mass ratio of 9:1:1:0.33.

[0044] A preparation method of modified polypropylene composite material, comprising the following steps:

[0045] Step 1, take the polypropylene of 90 weight parts, the styrene-butadiene thermoplastic elastomer of 10 weight parts, the talcum powder of 10 weight parts and the dicumyl peroxide of 3.3 weight parts;

[0046] Step 2. Add the polypropylene, styrene-butadiene thermoplastic elastomer and talcum powder in the above parts by weight to the internal mixer and mix them for the first internal mixing. The time is 4 minutes, the temperature is 168° C., and the rotation speed is 55 rpm;

[0047] Step 3, adding 3.3 parts by weight of dicumyl peroxide for the second banburying, the time is 4min, the temperature is 152°C, and the rotating speed is 43rpm;

[0048] Step 4, taking out the...

Embodiment 3

[0050] A modified polypropylene composite material is prepared by using polypropylene, styrene-butadiene thermoplastic elastomer, talcum powder and dicumyl peroxide in a mass ratio of 9:1:1:0.4 to prepare the modified polypropylene composite material.

[0051] A preparation method of modified polypropylene composite material, comprising the following steps:

[0052] Step 1, take by weighing the polypropylene of 90 parts by weight, the styrene-butadiene thermoplastic elastomer of 10 parts by weight, the talcum powder of 10 parts by weight and the dicumyl peroxide of 4 parts by weight;

[0053] Step 2. Add the polypropylene, styrene-butadiene thermoplastic elastomer and talcum powder in the above parts by weight to the internal mixer and mix them for the first internal mixing. The time is 5 minutes, the temperature is 170° C., and the rotation speed is 60 rpm;

[0054] Step 3, adding 4 parts by weight of dicumyl peroxide for the second banburying, the time is 5min, the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com