A kind of coal mine mine water underground purification treatment method

A purification treatment and mine water technology, applied in mining wastewater treatment, flocculation/sedimentation water/sewage treatment, separation methods, etc., can solve the problems of no oil removal measures, high one-time investment costs, lengthy process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

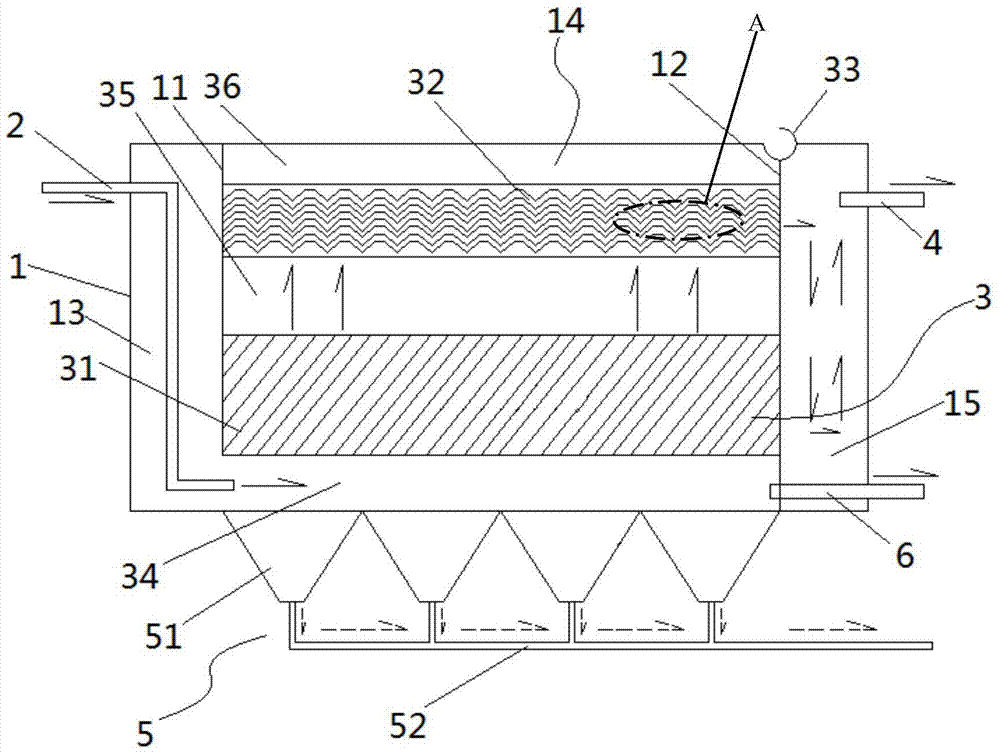

Embodiment 1

[0148] Adopt the purification equipment of the present invention to process the underground mine water of a mine in Shenhua Shendong, China, and the performance index parameters of the mine water are as follows:

[0149] Water volume: 10t / d (10 tons / day)

[0150] Suspended solids (SS): 65.8-316.5mg / L

[0151] Oil content (petroleum): 5.5-14.2mg / L

[0152] 1. Water intake and distribution

[0153] Downhole mine water flows into the water inlet area 13 of the cuboid pool of the purifying equipment of the present invention through the water inlet pipe 2, flows into the water distribution area 34 of the desilting-oil removal area 14 from the bottom of the pool, wherein: the flow velocity of the water flow is 1.0-1.5m / s, the volume of the pool is 25m3 ; The depth of the pool is 250cm; The volume of the inlet area is 2.5m 3 ;The volume of the desilting-deoiling zone is 20m 3 The height of the water distribution area is 50cm; the height of the top of the second dividing plate fro...

Embodiment 2

[0166] In step 1, except that the water velocity is 0.8-1.0m / s; the depth of the pool is 180cm; the height of the water distribution area is 30cm; the height of the top of the second partition from the upper edge of the pool is 30cm; The distance of the top of dividing plate is outside 30cm, and all the other are identical with embodiment 1;

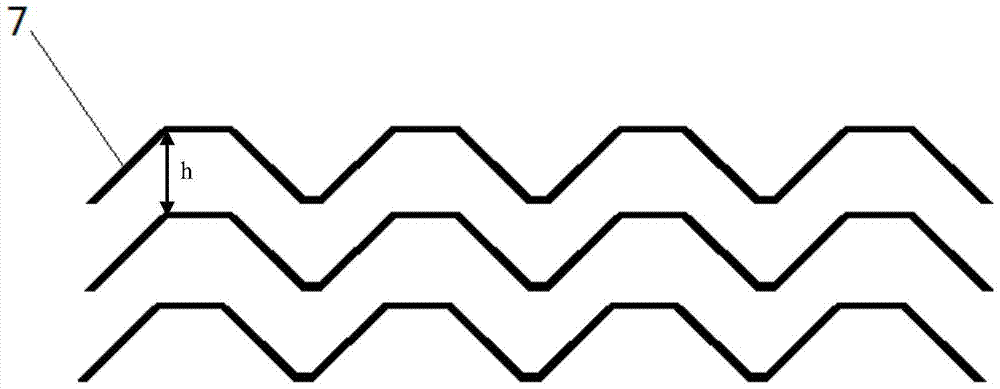

[0167] In step 2, except that the height of the inclined plate sedimentation packing layer is 30cm, the height of the bottom of the inclined plate sedimentation packing layer from the bottom of the pool is 60cm, and the water velocity is 0.8-1.0m / s, all the other are the same as in Example 1;

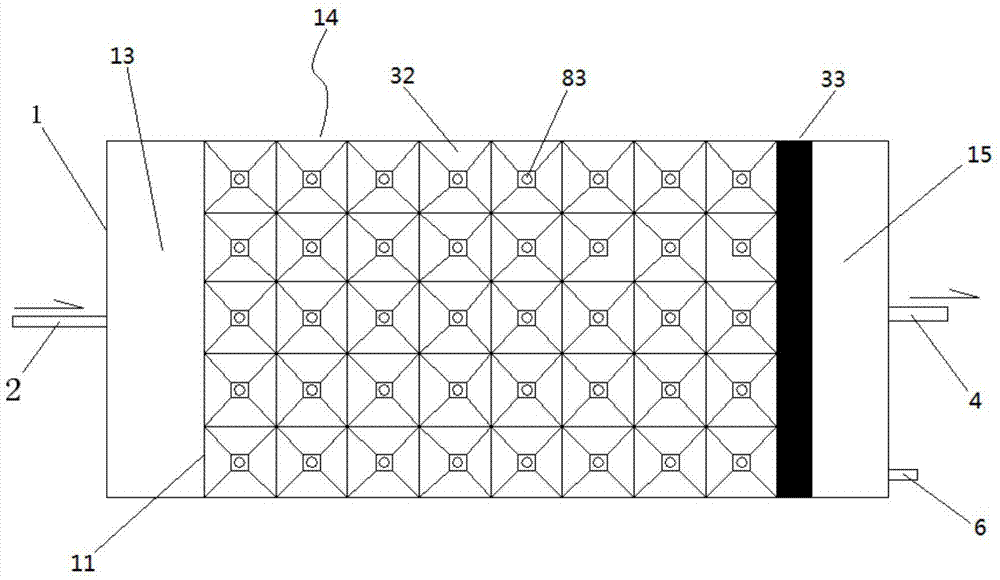

[0168] In step 3, except that the height of the buffer zone is 30cm, the water velocity is 0.8-1.0m / s, the height of the deoiling filler layer is 30cm, and the distance between two adjacent layers of deoiling filler sublayers is 7cm, it is a prism type The side length of the lower bottom surface of the oil removal unit is 5cm, and the side length ...

Embodiment 3

[0173] In step 1, except that the water velocity is 1.0-1.3m / s; the depth of the pool is 250cm, and the height of the water distribution area is 40cm; the height of the top of the second partition from the upper edge of the pool is 10cm; The distance of the top of plate is 30cm; Except, all the other are identical with embodiment 1;

[0174] In step 2, except that the height of the inclined plate sedimentation packing layer is 60cm, and the height of the bottom of the inclined plate sedimentation packing layer from the bottom of the pool is 50cm, all the other are the same as in Example 1;

[0175] In step 3, except that the height of the buffer zone is 50cm, the water velocity is 1.0-1.3m / s, the height of the deoiling filler layer is 60cm, and the distance between two adjacent layers of deoiling filler sublayers is 3cm, the positive truss type The side length of the lower bottom surface of the oil removal unit is 8cm, and the side length of the upper bottom surface is 3cm; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com