Pulse laser welding method and device assisted by electromagnetic force

A laser welding and auxiliary pulse technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of poor laser welding effect, enlarged welding heat affected zone, decreased weld toughness, etc. Inhomogeneity and stress concentration, improving comprehensive mechanical properties, and suppressing welding porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

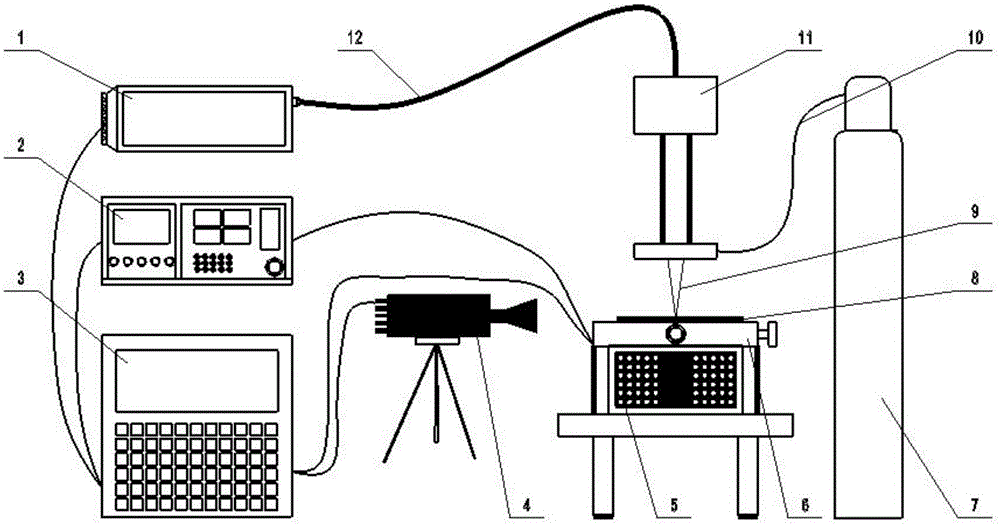

[0033] Such as figure 1 As shown, an electromagnetic force-assisted pulse laser welding device includes a laser generator 1, an optical transmission system 12, an optical focusing system 11, a clamping workbench 6, a protective gas supply device, a control system 3, and a pulse current generator 2. Electromagnetic conversion equipment 5, a high-speed camera 4 for collecting workpiece surface images, the laser generator 1, the pulse current generator 2, the high-speed camera 4, and the clamping workbench 6 are respectively connected to the control system 3, and the The laser generator 1 is connected to the optical focusing system 11 through the optical transmission system 12, the pulse current generator 2 is connected to the electromagnetic conversion device 5, the electromagnetic conversion device 5 is arranged under the workpiece 8, and the protective gas The gas supply port of the supply equipment is set at the welding seam of the workpiece 8, and the optical focusing system...

Embodiment 2

[0067] The welding equipment is as embodiment 1, and the welding method is specifically:

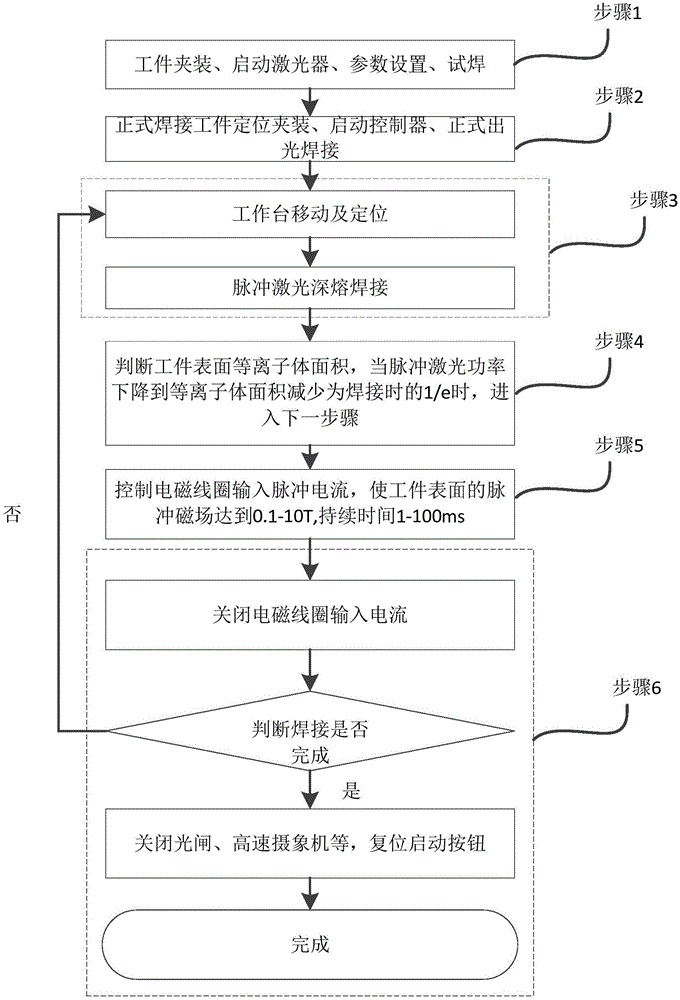

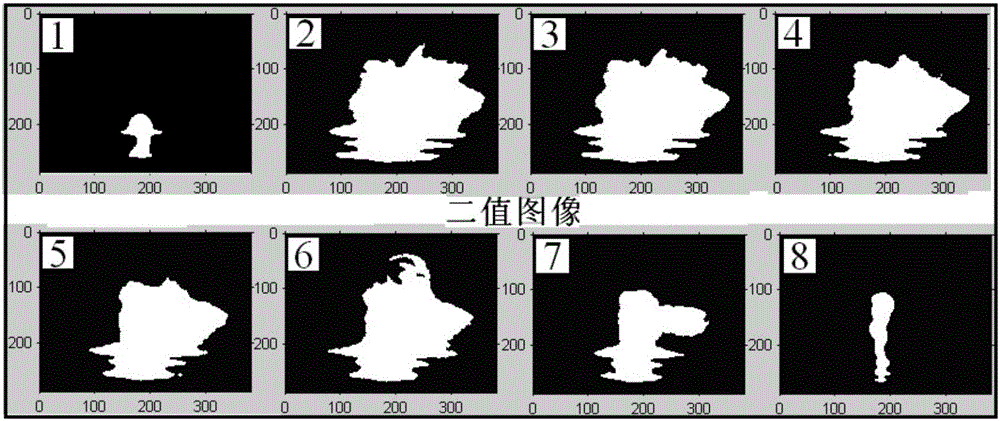

[0068] In this case, DISC laser pulse welding is used. According to the area change of the plasma binary map, when the welding pulse is about to end, that is, when the plasma area is 1 / e of the peak value of the plasma area during welding, the electromagnetic field is coupled to make the liquid metal generate electromagnetic force and accelerate Fills the "keyhole" and creates a uniform texture.

[0069] The thickness of the welded workpiece is 4mm6061 aluminum alloy plate, the welding process is butt welding, the distance between the welds is less than 0.05mm, the butt penetration is required to be greater than 2mm and penetration welding is not required, and the porosity is required to be less than 0.5%. A 7KW DISC laser is used for welding, modulated by a half-period sine wave with 6KW peak power at 100Hz, the interval between pulses is 10ms, the pulse width is 8ms, the spot diameter ...

Embodiment 3

[0075] The welding equipment is as embodiment 1, and the welding method is specifically:

[0076]In this case, 3KW semiconductor laser λ=915~940nm pulse welding is used. According to the change of the area of the plasma binary map, when the welding pulse is about to end, that is, when the plasma area is 1 / e of the peak value of the plasma area during welding, the electromagnetic field is coupled to make the liquid state The metal creates an electromagnetic force that accelerates the filling of the "keyhole" and creates a homogeneous structure.

[0077] The thickness of the welded workpiece is 2mm5052 aluminum alloy plate, the welding process is butt welding, the weld spacing is less than 0.05mm, butt welding is required, the penetration depth is 1±0.2mm, and the porosity is required to be less than 0.5%. 3KW semiconductor laser λ=915~940nm pulse welding is used for welding, the spot diameter is about 1.3mm, modulated by a triangle wave with 2.4KW peak power at 100Hz, after t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| Defocus amount | aaaaa | aaaaa |

| Defocus amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com