Handheld active control type spot welder for planting nails

An active control, spot welding technology, applied in welding power sources, manufacturing tools, welding equipment, etc., can solve the problems of low success rate, inability to hand-hold, large output current, etc. high current effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

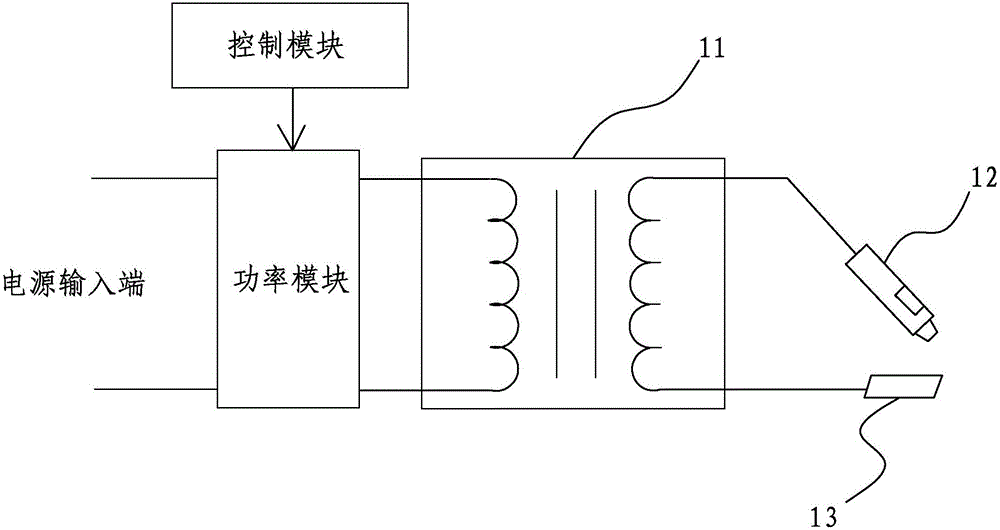

[0031] refer to Figure 3 to Figure 5 , a hand-held active control electric welding machine provided by the present invention includes a power supply module 31 and an operating handle 41, and the operating handle 41 is fixed with a main control board 32, a charging and discharging circuit, a power output board 34 and a welding head 42.

[0032] The charge and discharge circuit includes a charge switch 334 and several charge and discharge units 33 arranged in parallel, the charge and discharge unit 33 includes an electrolytic capacitor 331 and a discharge switch 332, each electrolytic capacitor 331 is correspondingly provided with a discharge switch 332, the charge switch 334 and the discharge switch 332. The discharge switches 332 are all MOSFET main control switches.

[0033] The power module 31 is used to convert the mains power into the voltage required for charging the main control board 32 and the charging and discharging circuit. The power module 31 can be a traditional ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com