Denitration catalyst terminal hardening liquid as well as preparation method and application thereof

A technology for denitrification catalyst and hardening solution, which is applied in the direction of catalyst activation/preparation, catalyst protection, chemical instruments and methods, etc. It can solve the problems of reduced overall catalyst strength, achieve good preparation and application performance, reduce production costs, and wear resistance Effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

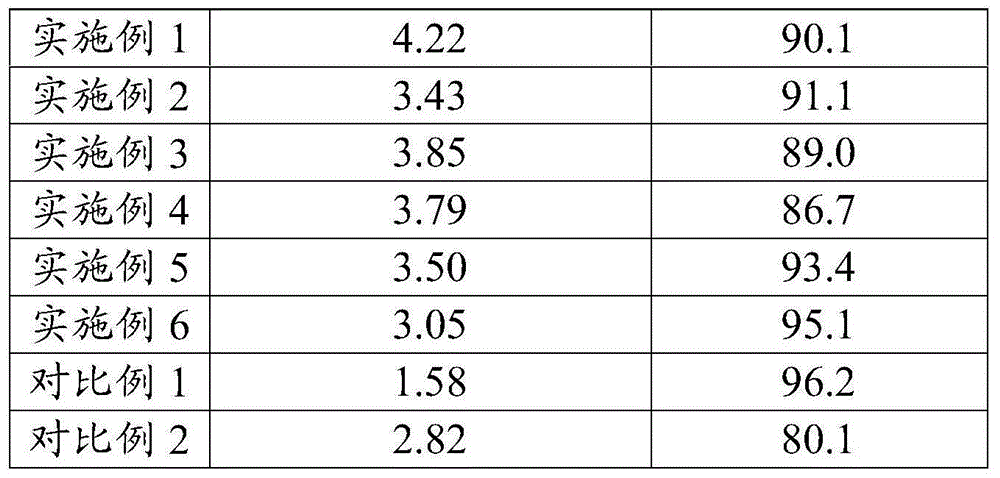

Examples

Embodiment 1

[0032] Prepare hardening solution according to the following formula and method:

[0033] (1) Dissolve 45g of phosphoric acid in 45g of deionized water and heat up to 60°C;

[0034] (2) Slowly add 10g of aluminum hydroxide in batches to (1) under stirring;

[0035] (3) heating to 120° C. for 2 hours to obtain a transparent solution;

[0036] (4) Add 0.5g of BYK-302 to (3) and stir evenly;

[0037] (5) Slowly add 4.5g of copper oxide powder, calcined at 950°C, the particle size is about 5-20μm, stir and disperse evenly to obtain the hardening solution.

[0038] The catalyst is impregnated according to the following process:

[0039] (1) After immersing 20 mm of the inlet end (or both ends of the air inlet and outlet) of the roasted and polished catalyst into the aforementioned hardening solution in stirring for 10 seconds;

[0040] (2) Blow off excess liquid with compressed air, and air-dry at room temperature for 5-8 hours;

[0041] (3) Catalyst treatment is completed by ...

Embodiment 2

[0044] Prepare hardening solution as follows:

[0045] (1) Dissolve 30g of phosphoric acid in 60g of deionized water and heat up to 60°C;

[0046] (2) Slowly add 10g of aluminum hydroxide in batches to (1) under stirring;

[0047] (3) heating to 120° C. for 2 hours to obtain a transparent solution;

[0048] (4) Add 0.5g of BYK-302 to (3) and stir evenly;

[0049] (5) Slowly add 4.5 g of copper oxide powder.

[0050] Dipping treatment process is the same as embodiment 1;

Embodiment 3

[0052] Prepare hardening solution as follows:

[0053] (1) Dissolve 60g of phosphoric acid in 30g of deionized water and heat up to 60°C;

[0054] (2) Slowly add 10g of aluminum hydroxide in batches to (1) under stirring;

[0055](3) heating to 120° C. for 2 hours to obtain a transparent solution;

[0056] (4) Add 0.5g of BYK-302 to (3) and stir evenly;

[0057] (5) Slowly add 4.5 g of copper oxide powder.

[0058] Dipping treatment process is the same as embodiment 1;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com