Hollow sphere adopting metal oxide/Pt/C three-layer nano structure and preparation method of hollow sphere

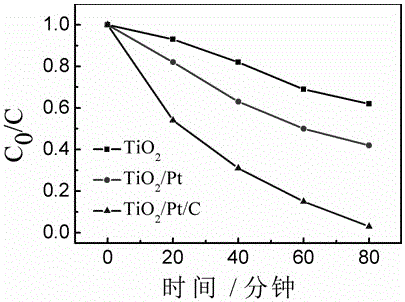

A nanostructure and oxide layer technology, applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of limiting solar energy utilization, waste of photogenerated electron holes, etc., and achieve the effect of low cost, simple method, and conducive to industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

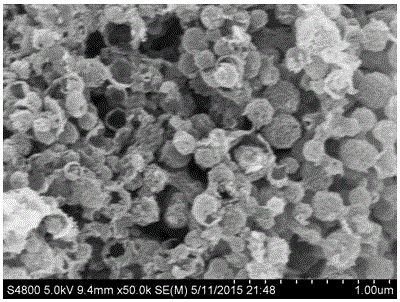

[0022] TiO 2 / Pt / C nano hollow spheres:

[0023] (1) 0.34g of tetrabutyl titanate is dissolved in 100mL of ethanol to obtain a 0.01M titanium ion solution, and then 0.1g of SiO with carboxyl and hydroxyl groups on the surface is added to the adsorption solution 2 Spherical template, ultrasonically disperse the spherical template, stir and adsorb for 4 hours, then centrifuge to obtain the adsorbed spherical template, place at 60°C, and dry for 6 hours;

[0024] (2) After the sample obtained in step (1) was heat-treated in air at 300°C for 60h, then immersed in a NaOH solution with a concentration of 1M at 60°C for 0.5h to remove SiO 2 Spherical template to obtain titanium oxide hollow spherical shell;

[0025] (3) the 10mgTiO obtained in step 2) 2 The hollow spheres were added to 10 mL of the noble metal platinum chloroplatinic acid solution with a concentration of 0.05 mg / mL, and the water in the solution was evaporated to dryness at 60° C. to collect samples. The obtained...

Embodiment 2

[0029] Bi 2 o 3 / Pt / C nano hollow spheres:

[0030] (1) 24g of bismuth nitrate pentahydrate was dissolved in 50mL of ethylene glycol to obtain a 1M bismuth ion solution, and then 0.5g of carbon spherical templates with carboxyl and hydroxyl groups on the surface were added to the adsorption solution, and the spherical template was fully dispersed by ultrasound, Stir and adsorb for 48 hours and then centrifuge to obtain the adsorbed spherical template, place it at 100°C and dry for 48 hours;

[0031] (2) The sample obtained in step (1) was heat-treated in air at 500°C for 20 hours to obtain Bi 2 o 3 Hollow spherical shell;

[0032] (3) The 100mgBi obtained in step 2) 2 o 3 The hollow spheres were added to 50 mL of 1 mg / mL chloroplatinic acid solution of noble metal platinum, and the water in the solution was evaporated to dryness at 100 ° C to collect samples. The obtained sample was heat-treated at 300 °C for 6 h in a hydrogen atmosphere to obtain Bi 2 o 3 / Pt nano ho...

Embodiment 3

[0035] CeO 2 / Pt / C nano hollow spheres:

[0036] (1) 21.7g of cerium nitrate hexahydrate was dissolved in 100mL of ethanol to obtain a 0.5M bismuth ion solution, and then 0.8g of PS spherical templates with carboxyl and hydroxyl groups on the surface were added to the adsorption solution, and the spherical templates were fully dispersed by ultrasound. Stir and adsorb for 12 hours, then centrifuge to obtain the adsorbed spherical template, place at 80°C, and dry for 24 hours;

[0037] (2) After the sample obtained in step (1) was heat-treated in air at 800 °C for 3 h, CeO 2 Hollow spherical shell;

[0038] (3) the 50mgCeO obtained in step 2) 2 The hollow spheres were added to 30 mL of the noble metal platinum chloroplatinic acid solution with a concentration of 0.5 mg / mL, and the water in the solution was evaporated to dryness at 80° C. to collect samples. The obtained sample was heat-treated at 250 °C for 4 h in a hydrogen atmosphere to obtain CeO 2 / Pt nano hollow sphere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com