Slurry Bed Reactor and Its Application in the Production of Hydrogen Peroxide

A reactor and slurry bed technology, applied in the field of chemical engineering, can solve the problems of large catalyst liquid holding capacity, degradation of working fluid, and low reaction selectivity, and achieve the effects of improving hydrogenation efficiency, uniform flow, and improving mass transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

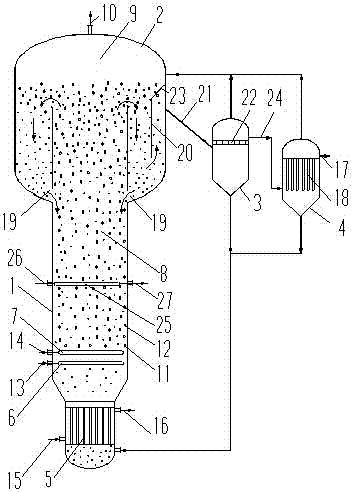

[0031] Such as figure 1 The slurry bed reactor shown comprises riser 1, expansion section 2, cooler 5, catalyst settler 3, filter 4; the expansion section is connected to the top of the riser, and the riser part extends into the expansion section. The riser in the expansion section is provided with a slurry return port 19, which communicates with the reaction chamber 8; the bottom of the riser is connected with the cooler 5, and the cooler and the riser are integrated; the upper part of the expansion section is a gas-liquid separation chamber 9, and the top A reaction gas outlet 10 is provided, and the middle and lower part of the expansion section is a catalyst pre-sedimentation area, and a baffle plate 20 is provided in the catalyst pre-sedimentation area to form a baffle isolation area. Catalyst settler 3 is connected by tangential feed pipe 21; Catalyst settler is fed from the middle by tangential mode, and catalyst settler top is provided with grille 22, and the top of ca...

Embodiment 2

[0042] Hydrogen efficiency determination method: take 5mL of hydrogenated liquid in a separatory funnel, then add 10mL of heavy aromatics and 20mL of H 2 SO 4 Solution (H 2 SO 4 The volume ratio of water and water is 1:4); pass O into the above mixed solution 2 , bubbling and oxidizing until bright yellow or orange (about 10-15min); wash the extraction reaction solution with pure water 4-5 times, about 20mL of water each time; add KMnO with a concentration of 0.1mol / L to the extraction solution 4 The standard solution is titrated to reddish, and the color does not fade in 30s as the end point. Then the hydrogen effect (gH 2 o 2 / L) = standard solution concentration (0.1mol / L) x standard solution volume (mL) x 17.01 / 5.

[0043] The catalyst used is: palladium carbon catalyst Pd110 produced by Yurui Chemical Co., Ltd. The specific parameters are as follows: precious metal content 10% ± 0.2%, specific surface area ≥ 950m 2 / g, metal surface area 85 ~ 105m 2 / g, the averag...

Embodiment 3

[0046] Attached figure 1 In the slurry bed reactor shown, the size of the reaction riser is Φ100×1000mm, the size of the expansion section is Φ150×300mm, and the height from the riser to the expansion section is 150mm; the filter has two sets of 400mm The sintered metal filter element filter components are set to automatically recoil when the pressure difference of each filter component reaches 0.05MPa, and the recoil liquid is the filtered reaction clear liquid.

[0047] Working liquid feed volume is 0.3 m 3 / h, the hydrogen feed rate is 5.0 Nm3 / h, the reaction temperature is 50-55°C, and the reaction pressure is 0.25-0.5 MPa.

[0048] The service life of the filter assembly is 60 hours, and the backwashing time is 40 seconds each time.

[0049] The hydrogenation efficiency reaches 12-14 g / L hydrogenated liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com