Module type permanent magnetic separation rolling machine

A magnetic separation roller and modular technology, which is applied in the field of modular permanent magnetic separation roller machines, can solve the problems of dust occurrence, unsuitable for large-scale fine-grained experiments, etc., and achieves easy disassembly, convenient observation and equipment operation. The effect of overhaul

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

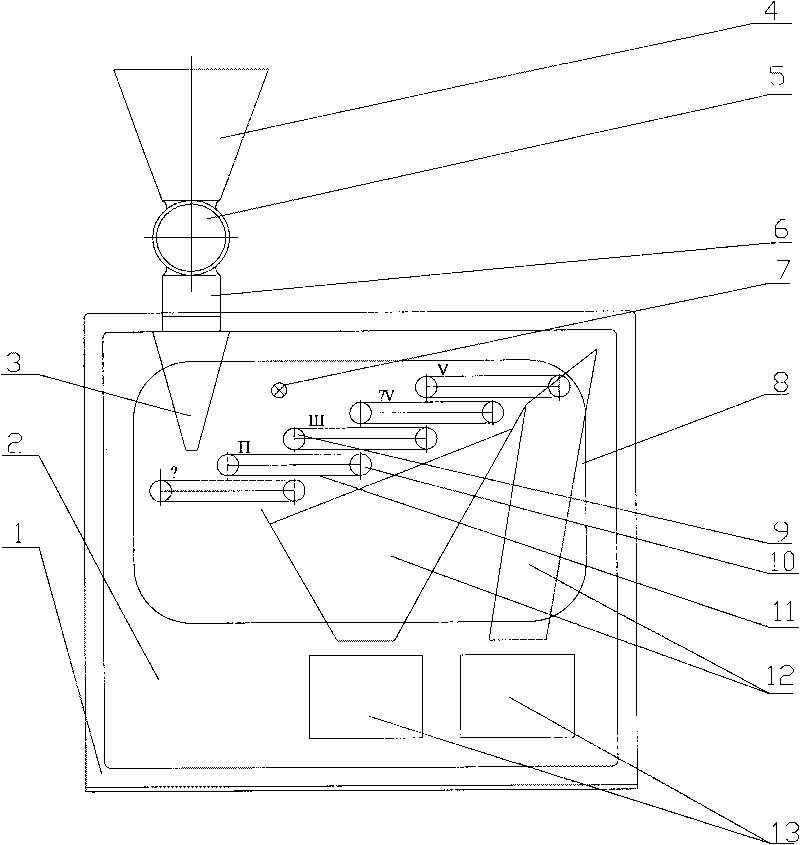

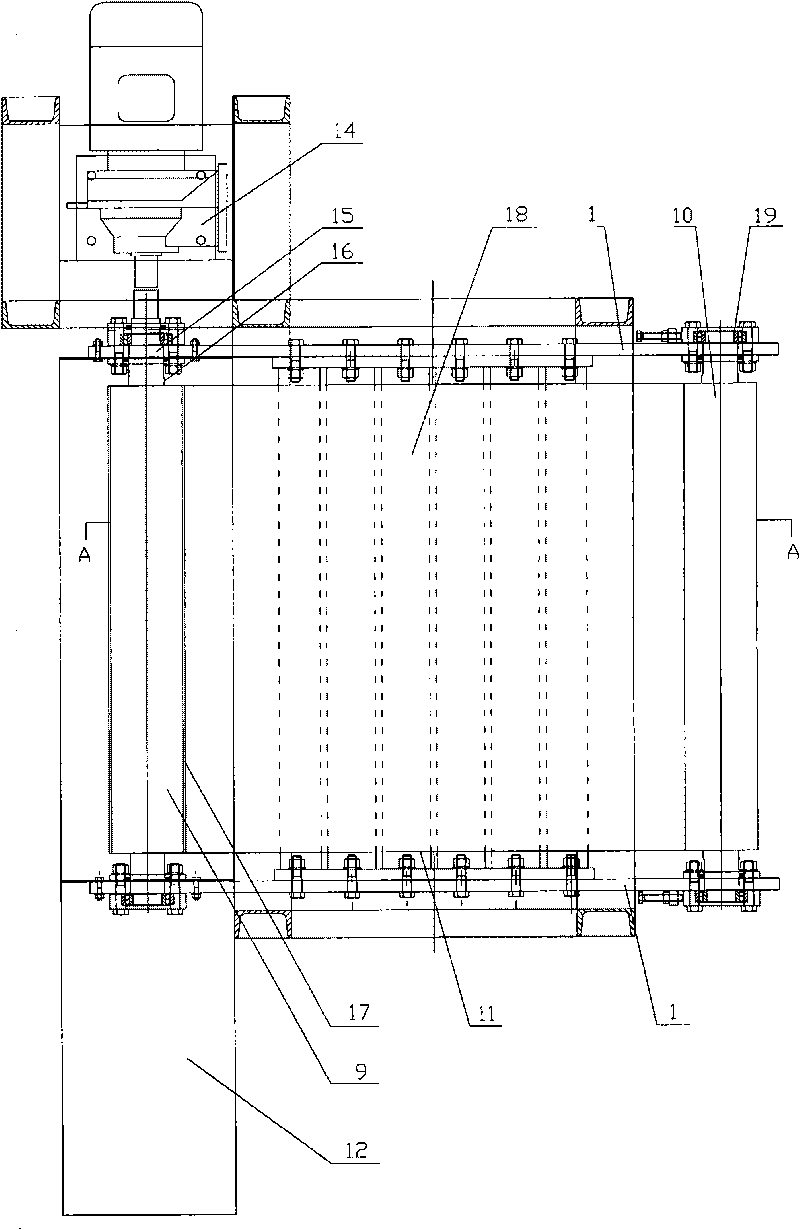

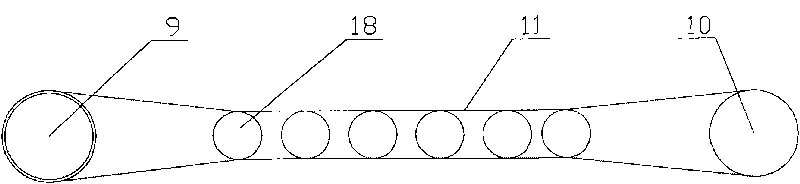

[0034] Such as figure 1 As shown, the modular permanent magnet magnetic roller type machine of the present invention comprises a frame 1, a belt conveyor driven by a transmission device that is installed in several layers on the frame successively in a stepped dislocation arrangement from bottom to top , and the feeding mechanism that is arranged on the feeding end of the belt conveyor, the receiving hopper 12 installed below the discharging end of the belt conveyor, the drawer type silo 13 that is located directly below the discharge port of the receiving hopper 12; The driving roller 9 (driving roller) of every layer of belt conveyor at the material end is a magnetic roller structure. The whole device is controlled by a PID control cabinet. The PID (proportional-integral-derivative) control cabinet is the most widely used regulator in engineering. Its contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com