Technology for recycling valuable metal from jarosite slag

A technology of valuable metals and alum slag, which is applied to the improvement of process efficiency and cement production, etc. It can solve the problems of polluting groundwater and soil, poor stockpiling, occupation, etc., and achieves separation, cheap price, and quicker reaction speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention reclaims the technique of valuable metal from jarosite slag specifically comprising:

[0024] (1) add dispersant in water, after stirring uniformly; add alum slag and reducing agent, stir uniformly; add lime, stir uniformly, obtain the solution containing ferric oxide and calcium sulfate precipitation;

[0025] (2) separating iron oxide and calcium sulfate precipitation from solution to obtain liquid;

[0026] (3) Add a hydrophobic agent and a floating agent to the liquid, and the hydrophobic agent selectively adsorbs on the surface of metal ions Zn and In, and under the action of the floating agent, floats on the surface of the liquid, scrapes the liquid containing metal on the surface, and recovers the metal .

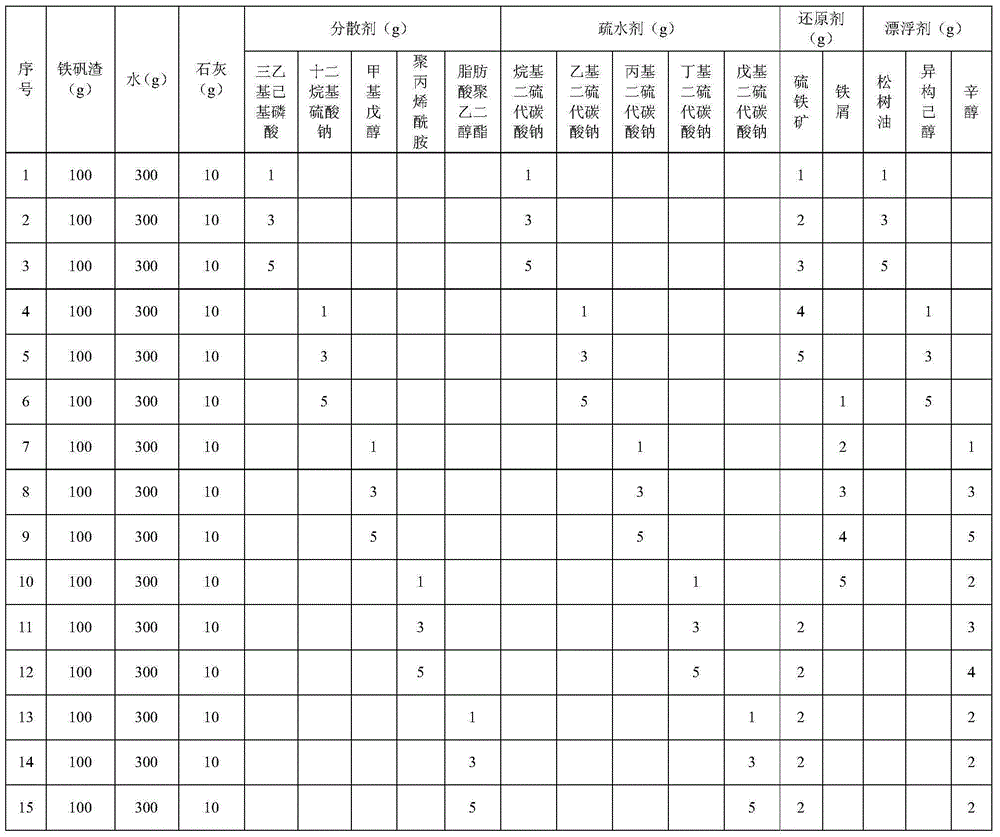

[0027] The types of various additives and their proportions with water and iron slag are shown in Table 1.

[0028] Comparing the amount of recovered metal with the amount of metal in the iron-aluminum slag, the recovery rate of metal i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com