A bioleaching method for strengthening chalcopyrite and bornite

A bioleaching and bornite technology, applied in the direction of improving process efficiency, can solve the problems of slow leaching rate and low microbial leaching rate, and achieve the effect of strengthening bioleaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

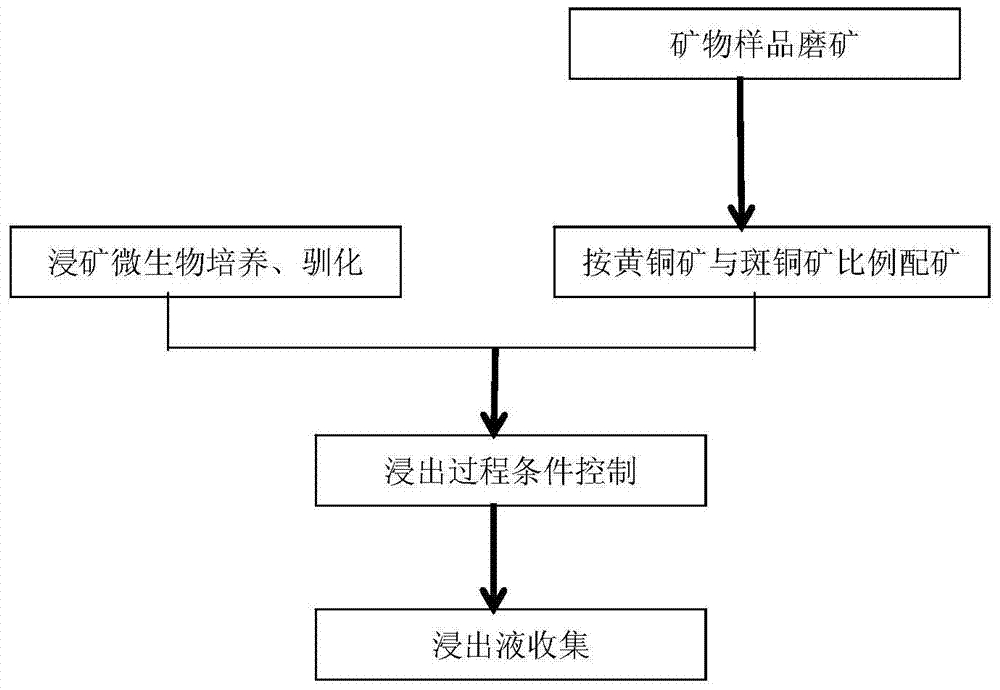

Method used

Image

Examples

Embodiment 1

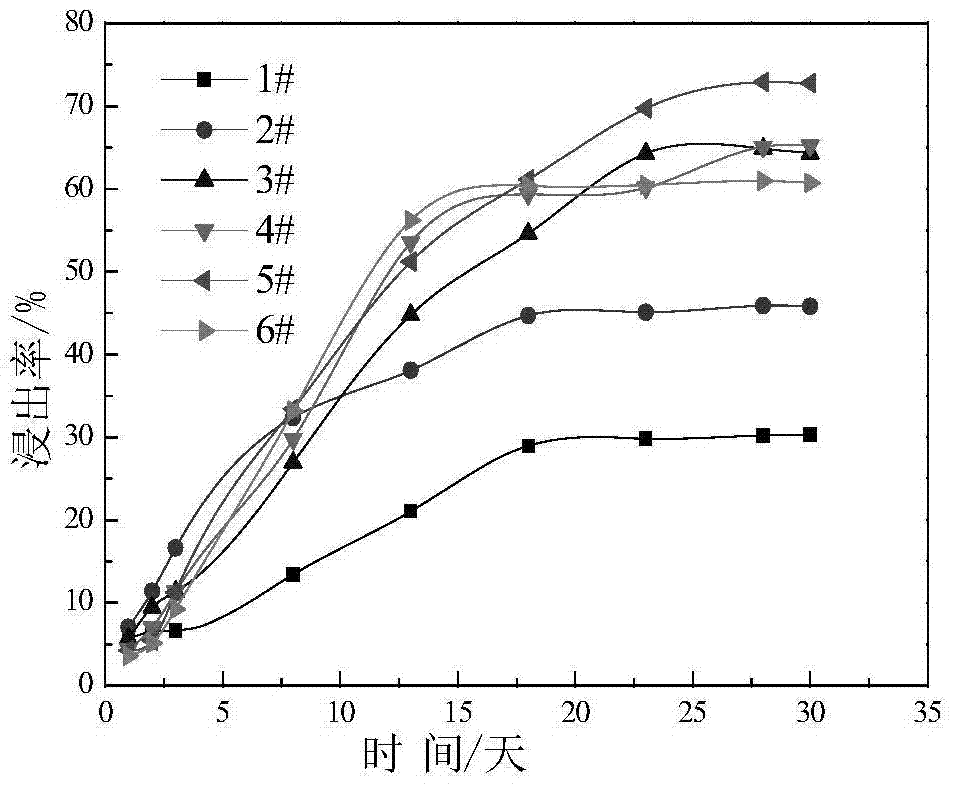

[0027] Example 1: Acidithiobacillus ferrooxidans (CCTCC AB206207) was selected as the ore leaching bacteria, and pure minerals of chalcopyrite and bornite were artificially mixed.

[0028] Comparison index: After 30 days of leaching, the leaching rate of chalcopyrite alone is 30%, and that of bornite is 60%; mineral samples are ground first until the content of -0.074mm reaches more than 80%, and chalcopyrite and bornite are controlled The mass ratio is 4:1-1:4; the stirring speed of the leaching process is controlled at 100-600rpm, the pH value of the leaching process is controlled at 1.5-2.5, and the solution potential is controlled at 350-480mV (Ag / AgCl is the reference electrode ), the Cu leaching rate is higher than that of chalcopyrite alone and bornite alone, and the highest Cu leaching rate can reach more than 73%. (See figure 2 )

[0029] In summary, the present invention significantly strengthens the bioleaching of chalcopyrite and bornite.

Embodiment 2

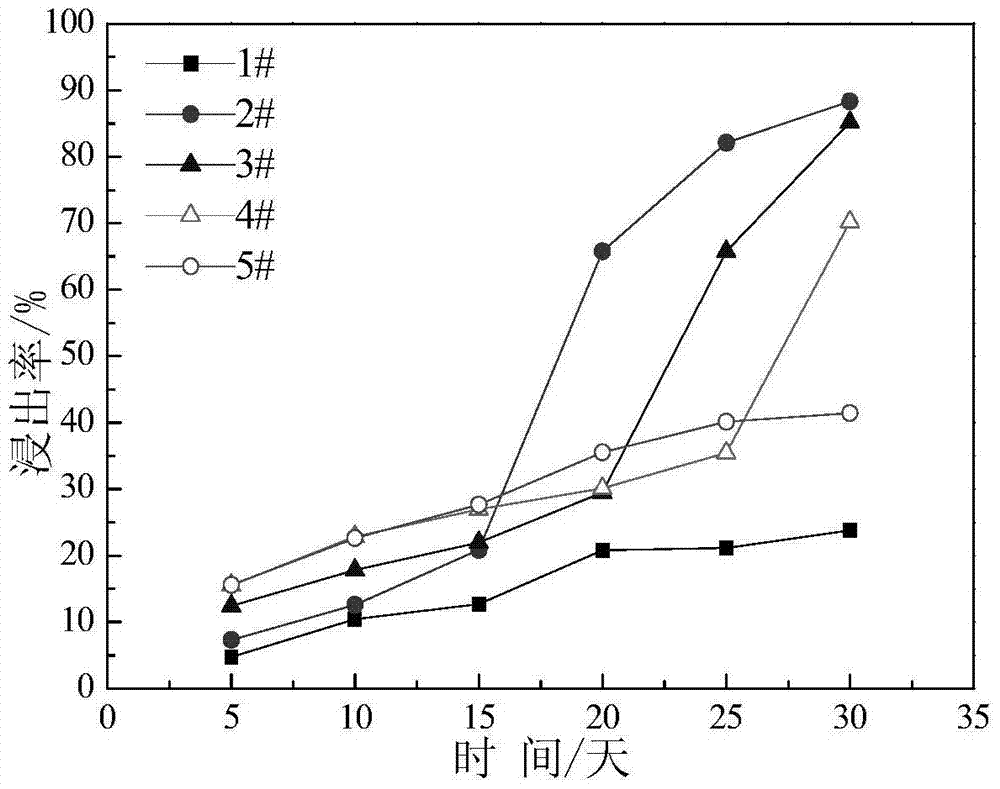

[0030] Example 2: Acidithiobacillus caldus (CCTCC AB 206240) was selected as the leaching bacteria to artificially mix chalcopyrite and bornite pure minerals.

[0031] Comparison index: After 30 days of leaching, the leaching rate of chalcopyrite alone is 23%, and that of bornite alone is 41%. The mass ratio is 5:1-1:5; the stirring speed of the leaching process is controlled at 100-600rpm, the pH value of the leaching process is controlled at 1.5-2.5, and the solution potential is controlled at 350-480mV (Ag / AgCl is the reference electrode ), the Cu leaching rate is higher than that of chalcopyrite alone and bornite alone, and the highest Cu leaching rate can reach more than 88%. (See image 3 )

[0032] In summary, the present invention obviously strengthens the bioleaching of chalcopyrite and bornite.

Embodiment 3

[0033] Example 3: Leptospirillum ferriphilum (CCTCC AB 206239) was selected as the leaching bacteria to artificially mix chalcopyrite and bornite pure minerals.

[0034] Comparison index: after leaching for 30 days, the leaching rate of chalcopyrite alone is 35%, and that of bornite is 48%. Mineral samples are ground first until the content of -0.074mm reaches more than 80%, and chalcopyrite and bornite are controlled The mass ratio is 5:1-1:5; the stirring speed of the leaching process is controlled at 100-600rpm, the pH value of the leaching process is controlled at 1.5-2.5, and the solution potential is controlled at 350-480mV (Ag / AgCl is the reference electrode ), the Cu leaching rate is higher than that of chalcopyrite and bornite alone, and the highest Cu leaching rate exceeds 95%. (See Figure 4 )

[0035] In summary, the present invention significantly strengthens the bioleaching of chalcopyrite and bornite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com