Powder coating with metal flashing effect, as well as preparation method and application method of powder coating

A metal flash and powder coating technology, applied in powder coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of high cost, man-hours, high energy consumption, labor consumption, and weakened product competitiveness. The effect of reducing installation costs, saving energy consumption and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The metal glitter effect powder coating described in the present embodiment is compounded by 3 components, and 3 components are respectively made of the raw materials of following percentage by weight:

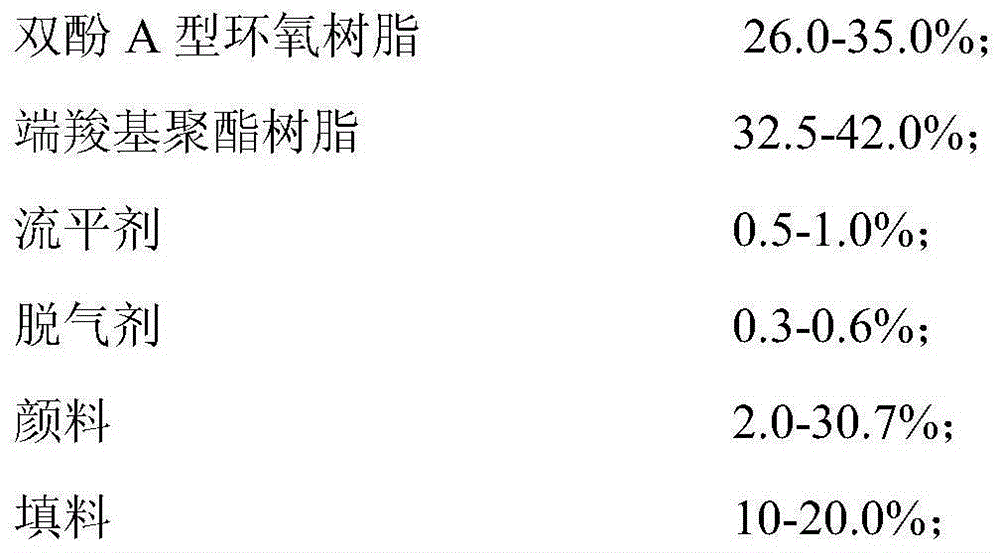

[0042] A component:

[0043]

[0044] B component:

[0045] A component 94.5%;

[0046] Flake copper powder pigment 2.0%;

[0047] Mica titanium pearlescent pigment 3.5%;

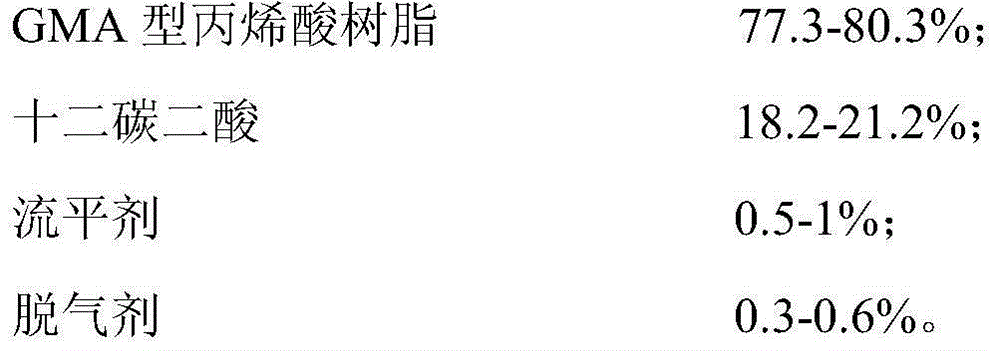

[0048] C component:

[0049]

[0050] The preparation method is as follows:

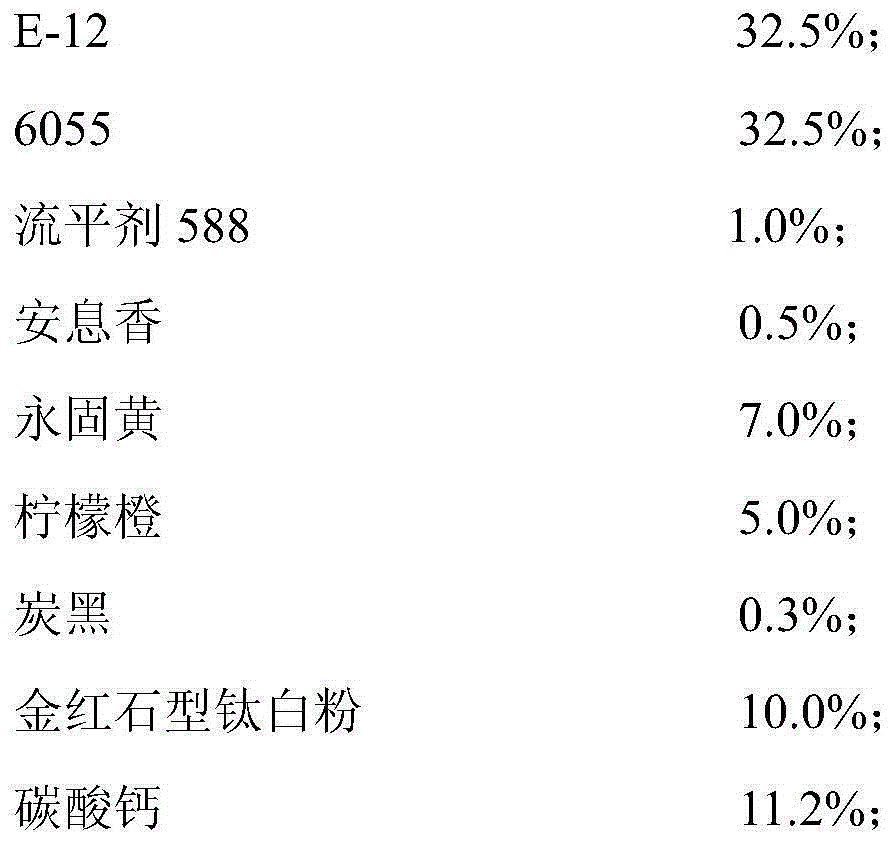

[0051] (1) Preparation of component A: After fully mixing E-12, 6055, leveling agent 588, benzoin, permanent yellow, lemon orange, carbon black, rutile titanium dioxide and calcium carbonate, in a twin-screw extruder Melt and extrude at 100°C, after cooling and tableting, pulverize with a jet mill, separate with a multi-stage cyclone separator, and sieve with a rotary sieve to obtain powder particles with an average particle size of 15-40 μm, which is component A.

[0052] (2) Preparation of component B: mix fla...

Embodiment 2

[0058] The metal glitter effect powder coating described in the present embodiment is compounded by 3 components, and 3 components are respectively made of the raw materials of following percentage by weight:

[0059] A component:

[0060]

[0061] B component:

[0062] A component 94.5%;

[0063] Flake aluminum powder pigment 1.0%;

[0064] Mica titanium pearlescent pigment 4.5%;

[0065] C component:

[0066]

[0067] The preparation method is as follows:

[0068] (1) Preparation of component A: After fully mixing E-12, 6055, leveling agent 588, benzoin, carbon black, rutile titanium dioxide and calcium carbonate, melt extrude in a single-screw extruder at 90°C , after cooling and tableting, pulverize with a jet mill, separate through a single-stage cyclone separator, and sieve with a rotary sieve to obtain powder particles with an average particle size of 15-40 μm, which is component A.

[0069] (2) Preparation of component B: mix flake aluminum powder pigment and...

Embodiment 3

[0075] The metal glitter effect powder coating described in the present embodiment is compounded by 3 components, and 3 components are respectively made of the raw materials of following percentage by weight:

[0076] A component:

[0077]

[0078] B component:

[0079] A component 95.5%;

[0080] Mica titanium pearlescent pigment 4.5%;

[0081] C component:

[0082]

[0083]

[0084] The preparation method is as follows:

[0085] (1) Preparation of component A: After fully mixing E-12, 6055, leveling agent 588, benzoin, carbon black and calcium carbonate, melt and extrude in a twin-screw extruder at 80°C, cool and press Finally, pulverize with a jet mill, separate through a single-stage cyclone separator, and sieve with a rotary sieve to obtain powder particles with an average particle size of 15-40 μm, which is component A.

[0086] (2) Preparation of component B: mix the mica titanium pearlescent pigment with the component A prepared in step (1) in a bonding m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com