Lignin solvent and preparation method therefor and application thereof

A technology for lignin and solvent, applied in the field of lignin solvent and its preparation, can solve the problems of high price, high viscosity and high temperature for separating lignin, and achieve the effects of strong practicability, saving raw materials and energy, and reducing investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A lignin solvent comprising 50% water and 50% Tween 80 by weight. Take 50% water and 50% Tween 80 according to weight percentage, add Tween 80 into water, stir evenly to obtain lignin solvent.

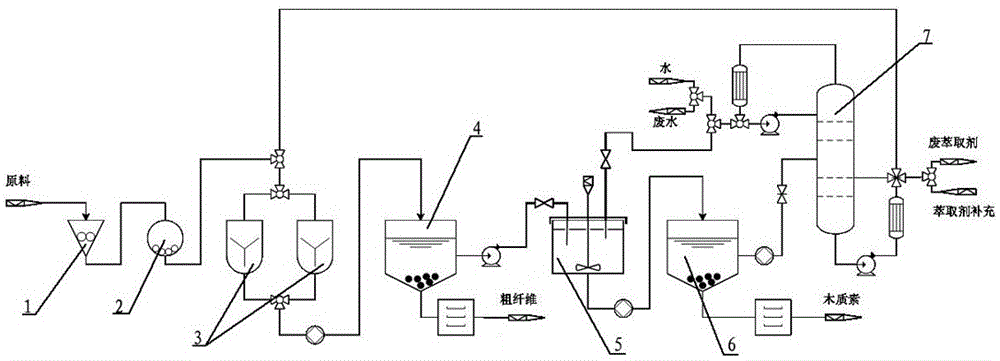

[0022] The application of lignin solvent of the present invention in lignin separation and extraction specifically comprises the following steps: figure 1 A flow chart of the lignin separation and extraction method is shown:

[0023] 1) Pass 1 kg of lignin-containing rice straw through a crusher and a spherical mill in sequence to obtain crushed materials;

[0024] 2) Add the pulverized material into the stirring extraction tank filled with lignin solvent, and stir at room temperature for 2 hours to obtain a mixed slurry;

[0025] 3) Pump the mixed slurry after stirring and extraction into the sedimentation tank for solid-liquid separation. The liquid phase is lignin solution, and the solid phase is dried by a dryer to become crude cellulose product;

[0026] 4) Pump the lig...

Embodiment 2

[0032] A lignin solvent comprising 90% water and 10% Tween 80 by weight. Take 90% water and 10% Tween 80 according to weight percentage, add Tween 80 into water, stir evenly to obtain lignin solvent.

[0033] The application of lignin solvent of the present invention in lignin separation and extraction specifically comprises the following steps:

[0034] 1) Pass 1 kg of lignin-containing rice straw through a crusher and a spherical mill in sequence to obtain crushed materials;

[0035] 2) Add the pulverized material into the stirring extraction tank filled with lignin solvent, and stir at room temperature for 2 hours to obtain a mixed slurry;

[0036] 3) Pump the mixed slurry after stirring and extraction into the sedimentation tank for solid-liquid separation. The liquid phase is lignin solution, and the solid phase is dried by a dryer to become crude cellulose product;

[0037] 4) Pump the lignin solution into the washing extraction tank and stir for 30 minutes. The stirre...

Embodiment 3

[0044] A lignin solvent comprising 60% water and 40% Tween 80 by weight. Take 60% water and 40% Tween 80 according to weight percentage, add Tween 80 into water, stir evenly to obtain lignin solvent.

[0045] The application of lignin solvent of the present invention in lignin separation and extraction specifically comprises the following steps:

[0046] 1) Pass 1 kg of lignin-containing rice straw through a crusher and a spherical mill in sequence to obtain crushed materials;

[0047] 2) Add the pulverized material into the stirring extraction tank filled with lignin solvent, and stir at room temperature for 2 hours to obtain a mixed slurry;

[0048] 3) Pump the mixed slurry after stirring and extraction into the sedimentation tank for solid-liquid separation. The liquid phase is lignin solution, and the solid phase is dried by a dryer to become crude cellulose product;

[0049]4) Pump the lignin solution into the washing extraction tank and stir for 30 minutes. The stirred...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com