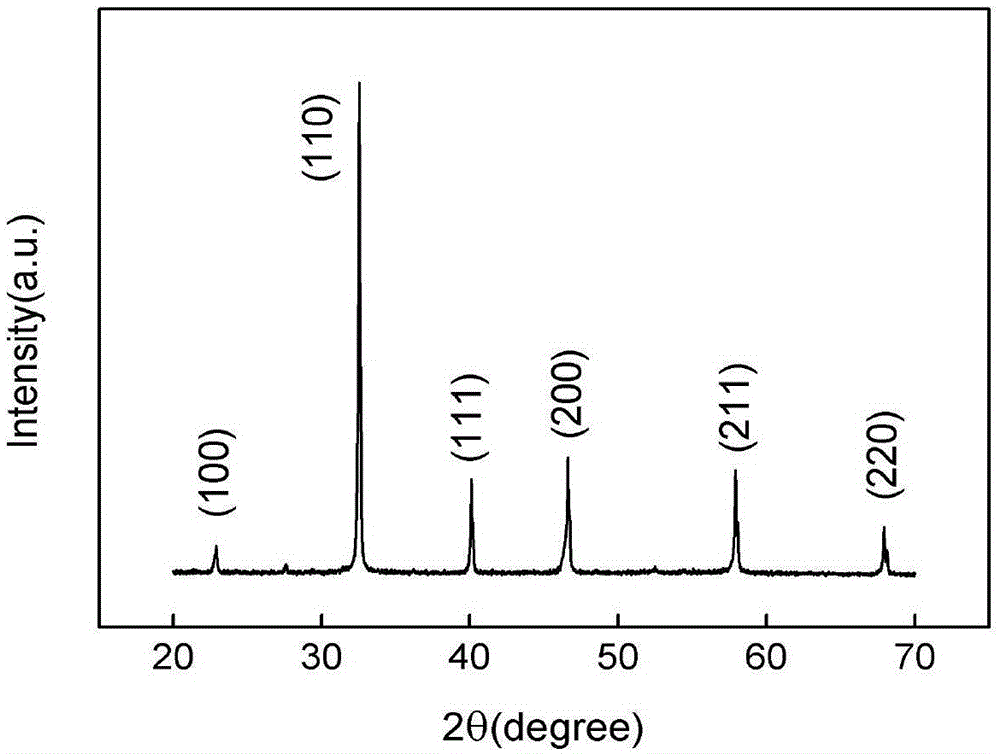

Sodium-bismuth-titanate-base lead-free electrostrictive ceramic material and preparation method thereof

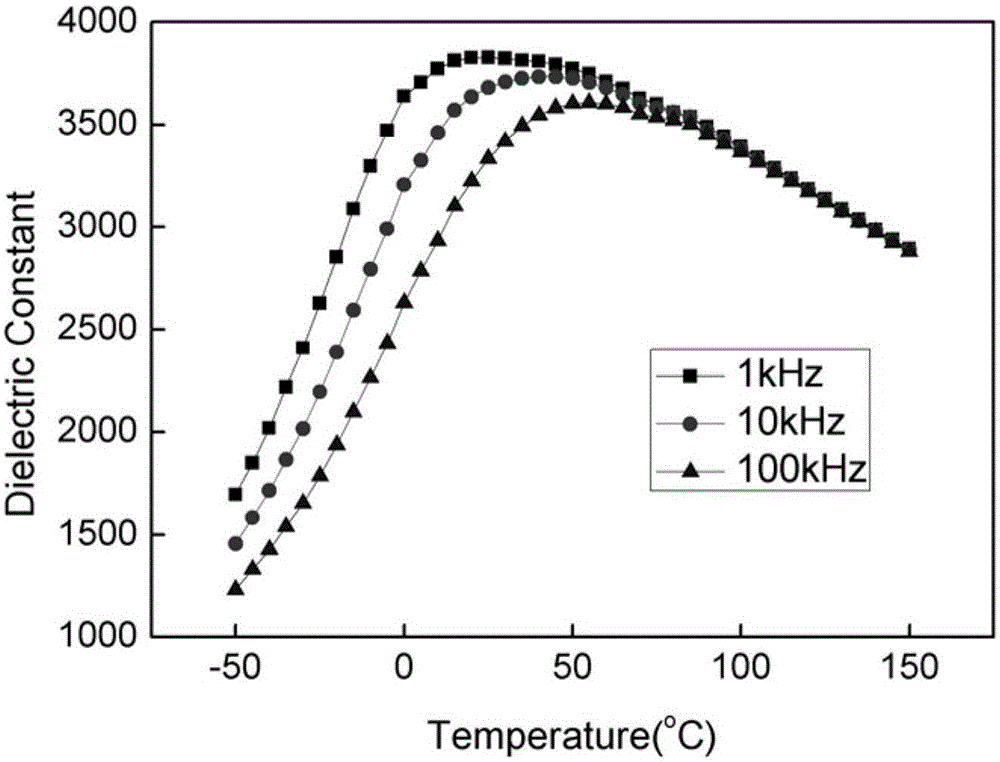

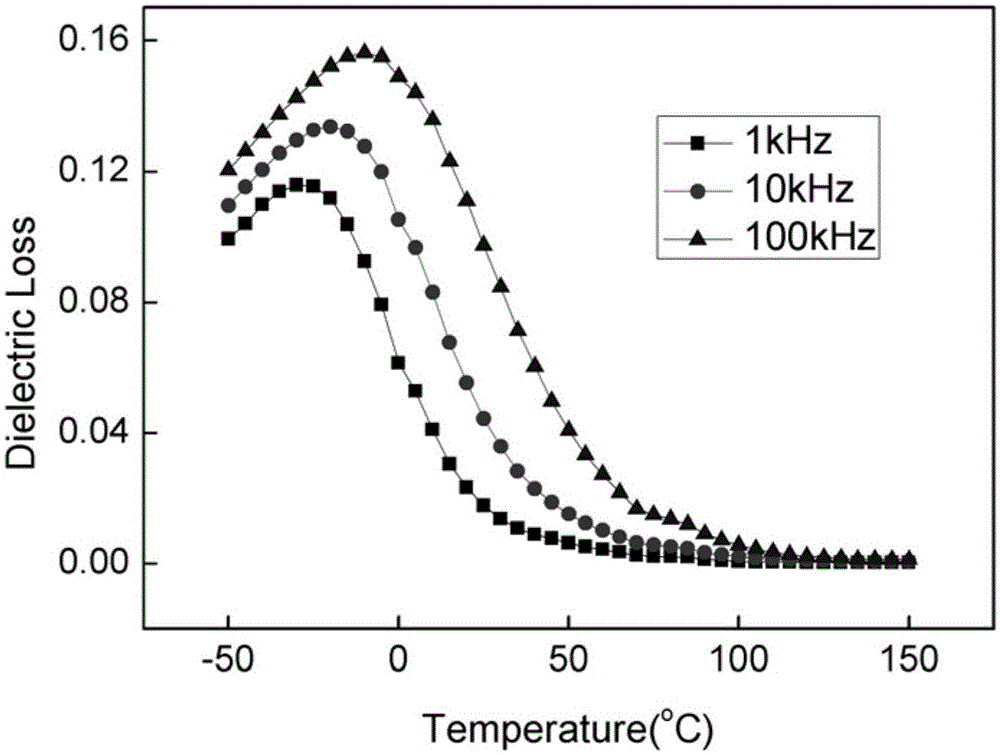

A technology of sodium bismuth titanate-based and ceramic materials is applied in the field of electrostrictive ceramics, which can solve the problems of pollution of lead-based electrostrictive materials and achieve the effect of good dielectric relaxation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0037] 1. Will analyze pure raw NaCO 3 , Bi 2 o 3 ,TiO 2 According to (Na 0.5 Bi 0.5 )TiO 3 Stoichiometric weighing, mixed ball milling, the ball milling medium is ethanol, the rotating speed is 400r / min, and the ball milling time is 10h.

[0038] 2. Wash out the ball-milled slurry in step 1, put it in an oven at 100°C for drying, grind and compact it, put it in a muffle furnace and raise the temperature to 800°C at a uniform speed at a rate of 3°C / min, and keep it warm for 2 hours , cooled to room temperature in the furnace, and ground to obtain powder A.

[0039] 3. Will analyze the pure raw material SrCO 3 ,TiO 2 According to SrTiO 3 The stoichiometric ratio is weighed, and mixed ball milling is carried out, the ball milling medium is ethanol, the rotating speed is 400r / min, and the ball milling time is 10h.

[0040] 4. Wash out the ball-milled slurry in step 3, put it in an oven at 100°C for drying, grind and compact it, put it in a muffle furnace and raise the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com