A continuous rubber mixing device

A mixing and rubber technology, applied in the field of polymer molding processing, can solve the problems of reducing process steps, uneven mixing quality of internal mixer, etc., and achieve simplified process steps, less uneven mixing effect, and large meshing times Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

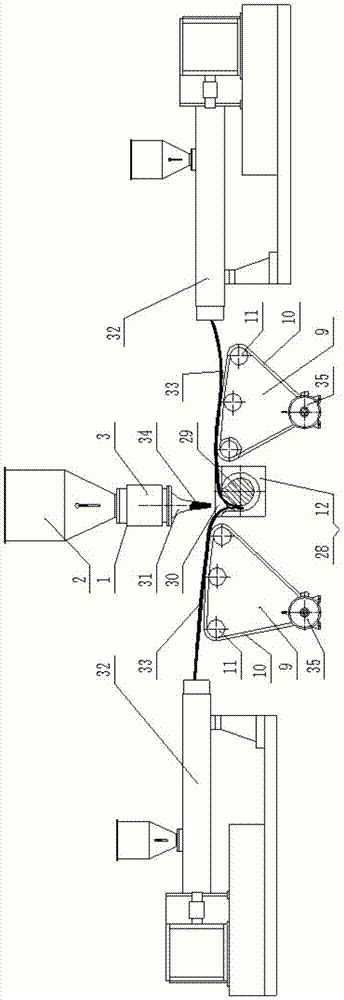

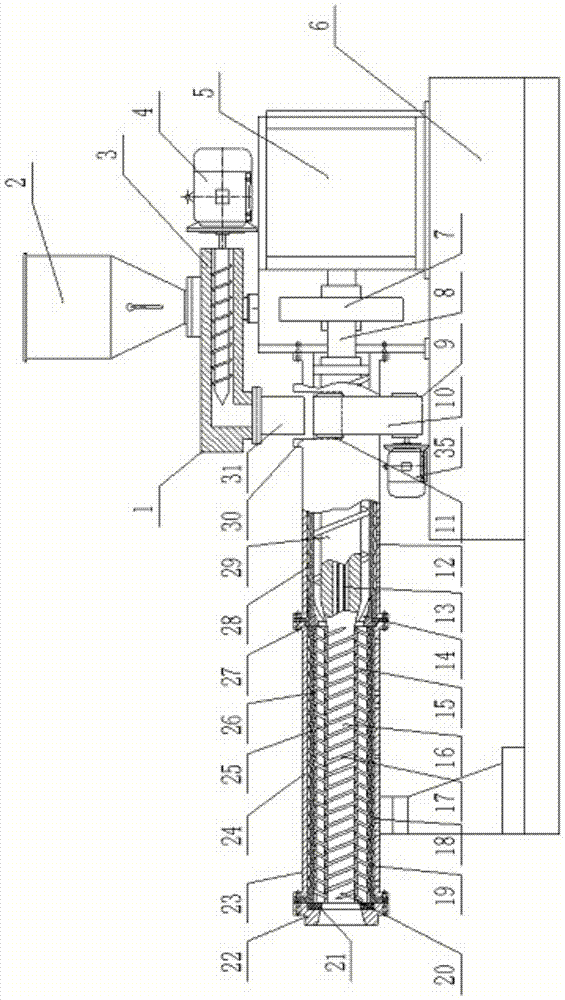

[0030] Such as figure 1 and figure 2 As shown, a rubber continuous mixing device of the present invention is mainly composed of compounding agent metering supply device 1, film metering and conveying device 9, barrel 22, main screw 20, planetary screw 15, rear brake ring 27, front brake ring 21. Die 22, transmission device 7, drive device 5, frame 6, etc., main screw 20 is composed of screw planetary section 16, screw feeding section 29 and screw transmission section 8 in turn, and the center of main screw 20 is from the transmission section 8. Blind holes are opened, and the cooling pipeline 13 is installed inside; the barrel 23 is composed of the inner barrel 19 of the planetary section, the outer barrel 24 of the planetary section, the inner barrel 28 of the feeding section, and the outer barrel 12 of the feeding section, and the inner barrel of the planetary section 19 is located inside the outer barrel 24 of the planetary section and is fixedly connected with it. The in...

Embodiment 2

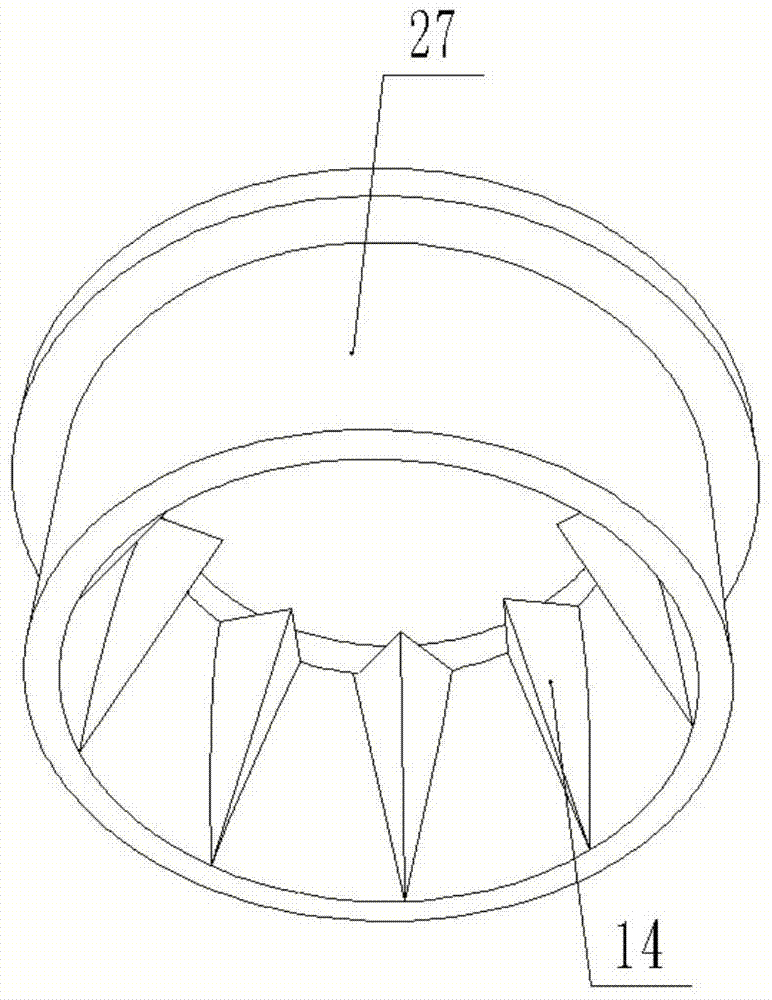

[0035] Such as Figure 7 As shown, the structure, working principle and effect of this embodiment and embodiment 1 are basically the same, the difference is: its blade 14 is not arranged on the rear brake ring 27, but is arranged on the feeding material contacting with the rear brake ring 27 rear end The position of the inner wall of the cylinder 28 in the section.

[0036] Because the material is not conveyed in a straight line forward along the axial direction of the machine barrel 23 in the process of advancing, but there is a certain helical angle. The blade 14 for cutting material will be subject to the lateral force of the material, and the blade 14 is arranged on the barrel 28 in the feeding section instead of on the rear brake ring 27, which will reduce the external force on the rear brake ring 27 and slow down the rear brake ring 27. Damage to the moving ring 27.

Embodiment 3

[0038] Such as Figure 8 As shown, the structure, working principle and effect of this embodiment are basically the same as those of Embodiment 1, the difference is that the front brake ring 21 has a hole, the planetary screw 15 and the front brake ring 21 are axially fixed and can rotate, and the planetary section The machine barrel 19 and the outer machine barrel 24 of the planetary section are axially fixed and rotatable. The number of blades of the rear brake ring 27 is consistent with the number of the planetary screw 15, and the circumferential position of each blade 14 is consistent with the circumferential position of the planetary screw 15. The number of the planetary screw 15 and the blades 14 should be large enough to ensure that the cross-sectional area of the planetary screw gap is not greater than the cross-sectional area of the planetary screw 15 .

[0039] The working principle of this structure is that the main screw 20 rotates and engages to make the plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com