Welding method for aluminum-steel composite member and aluminum-steel composite member

A welding method and technology of composite parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a welding method for aluminum-steel composite parts, comprising the following steps:

[0032] S1: Use plate-like aluminum parts with a surface roughness of Ra1.6 and cylindrical steel parts with a surface roughness of Ra1.6. The thickness of the aluminum part is 9mm, the diameter of the steel part is 20mm, and the aluminum part is 1060 Pure aluminum, steel parts are 304 stainless steel;

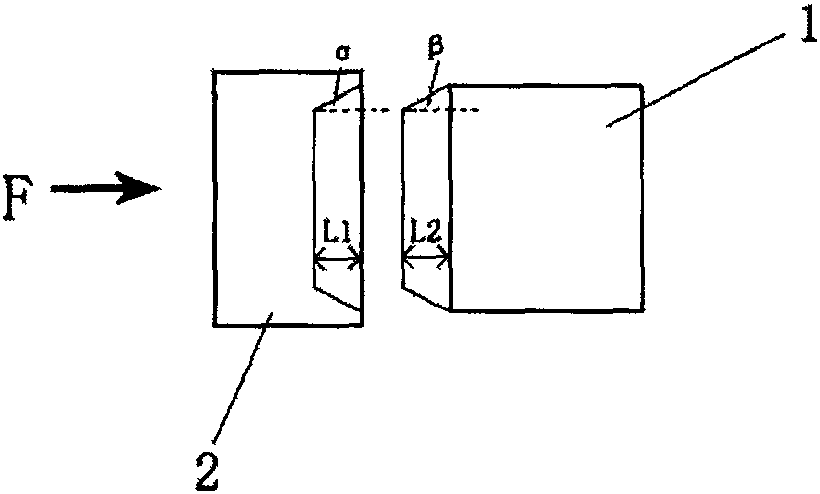

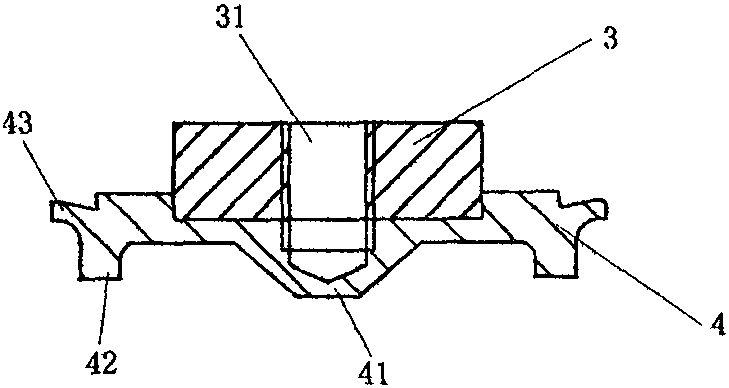

[0033] S2: Fix the aluminum parts and steel parts, and make the plate surface of the aluminum part and the end face of the steel part align and contact to form a welding surface, and apply a force to the steel part and perpendicular to the welding surface on the aluminum part The force or the component of the force, so that the force or the component of the force produces a pressure of 280KN on the welding surface;

[0034] S3: Keep the pressure on the welding surface, and make the steel part rotate relative to the aluminum part, the rotation speed is 300 rpm,...

Embodiment 2

[0039] S1: Use plate-like aluminum parts with a surface roughness of Ra1.6 and cylindrical steel parts with a surface roughness of Ra5.6. The thickness of the aluminum parts is 10mm, and the diameter of the steel parts is 21mm;

[0040] S2: Fix the aluminum parts and steel parts, and make the plate surface of the aluminum part and the end face of the steel part align and contact to form a welding surface, and apply a force to the steel part and perpendicular to the welding surface on the aluminum part The force or the component of the force, so that the force or the component of the force produces a pressure of 320KN on the welding surface;

[0041] S3: Keep the pressure on the welding surface, and make the steel part rotate relative to the aluminum part, the rotation speed is 400 rpm, stop the rotation of the steel part after 3s, and make the steel part rotate during the rotation of the steel part. The parts are gradually inserted into the aluminum parts at a speed of 0.8mm / s...

Embodiment 3

[0046] S1: Use plate-like aluminum parts with a surface roughness of Ra6.3 and cylindrical steel parts with a surface roughness of Ra4.6. The thickness of the aluminum parts is 13mm, and the diameter of the steel parts is 23mm;

[0047] S2: Fix the aluminum parts and steel parts, and make the plate surface of the aluminum part and the end face of the steel part align and contact to form a welding surface, and apply a force to the steel part and perpendicular to the welding surface on the aluminum part The force or the component of the force, so that the force or the component of the force produces a pressure of 380KN on the welding surface;

[0048] S3: Keep the pressure on the welding surface, and make the steel part rotate relative to the aluminum part, the rotation speed is 500 rpm, stop the rotation of the steel part after 4s, and make the steel part rotate during the rotation of the steel part. The parts are gradually inserted into the aluminum parts at a speed of 0.9mm / s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com