A kind of non-heat pretreatment method for making sweet corn juice

A sweet corn juice and pretreatment technology, which is applied in the field of sweet corn juice production, can solve the problems of loss of natural fresh and tender flavor of sweet corn, reduce the freshness of sweet corn juice, and affect appearance and taste, so as to avoid flavor loss and simplify processing. Steps to avoid the effect of raw taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

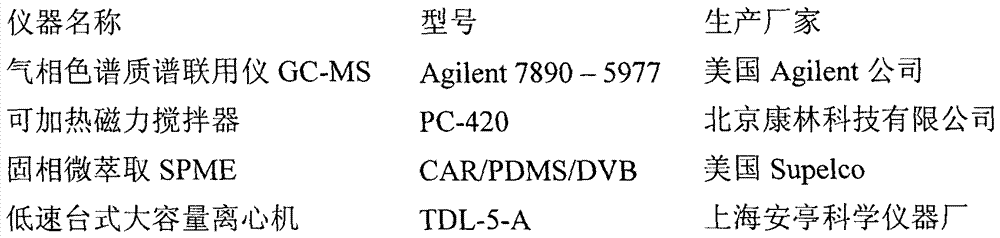

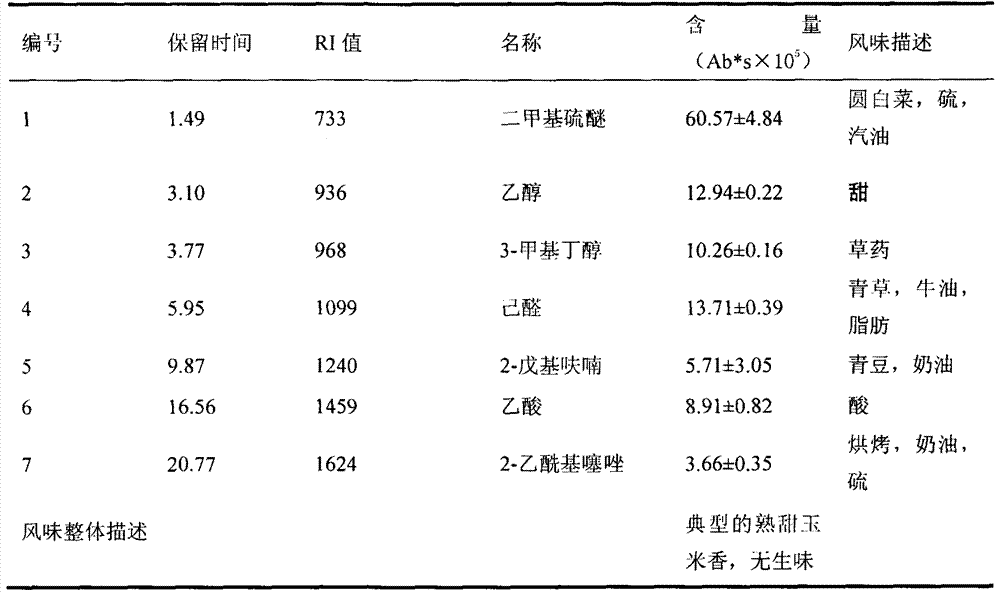

[0026] Weigh 100.0 g of fresh Jingtian No. 5 corn respectively, add 400 mL of purified water (A) or 0.1 mol / L disodium hydrogen phosphate solution (B), use a colloid mill to homogenize, transfer it into four 250 mL centrifuge cups, and centrifuge at 4,000 × g , pour out the upper corn juice for corn juice. 15 mL of each of the two samples was added to three extraction bottles, each with 5 mL, and SPME-GC-MS was used to analyze the volatile components and conduct sensory evaluation.

[0027] Table 1 Effects of pH adjustment pretreatment on volatile components and odor of fresh corn juice

[0028]

[0029] As shown in Table 1, there are many volatile aldols and ketones in the fresh sweet corn juice of raw jade, which are mostly described as green and related to fat oxidation. Adjusting the pH value to 9.0 means that treatment B effectively reduces the production of these components. , the number of aldols and ketones was reduced from 9 to 4, and the detected four ethanol, he...

Embodiment 2

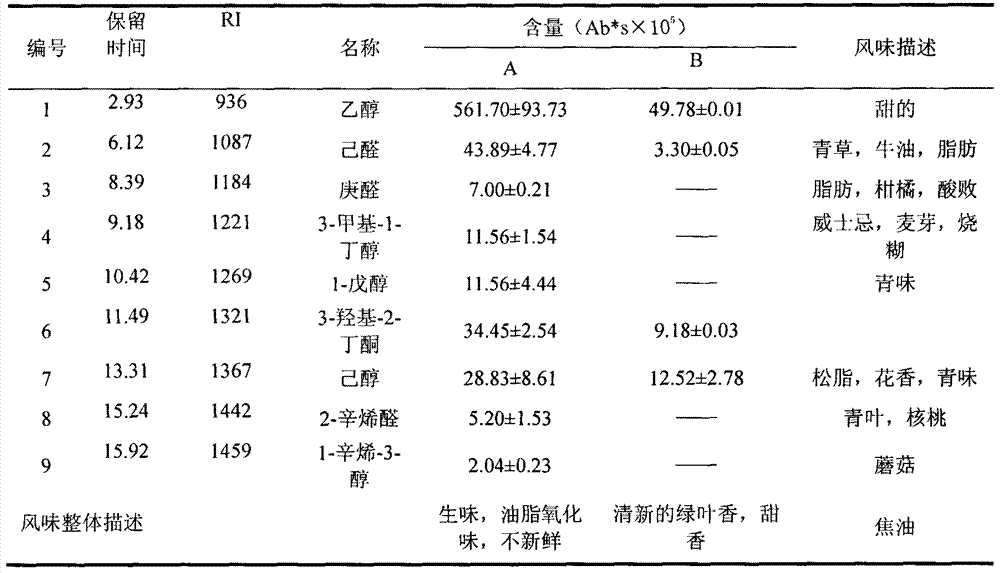

[0031] Weigh 100.0 g of fresh Jingtian No. 5 corn, add 2 L of boiling water to blanched for 4 minutes, remove and drain, add 400 mL of purified water, use a colloid mill to homogenize at 4,000 × g and centrifuge, and pour out the upper layer of corn juice to be the original corn juice. . The corn juice was heated to boiling on an induction cooker, and then the power was turned off, and cooled to 40° C. or 50° C. The same as in Example 1, volatile component analysis and odor analysis were performed.

[0032] Table 2 Effects of blanching pretreatment on volatile components and odor of corn juice

[0033]

[0034] As shown in Table 2, on the one hand, the blanching pretreatment effectively reduced the progress of the fat oxidation reaction, and only three aldol substances, ethanol, 3-methyl butanol, and hexanal, were detected. On the other hand, due to heating, dimethyl sulfide, 3-methyl butanol, 2-pentyl furan, 2-acetyl thiazole were detected. These components were derived f...

Embodiment 3

[0036] The corn juice obtained in Example 1 and Example 2 was put into a high-temperature steam sterilizer at 121°C, cooled to 40°C, and analyzed for volatile components and odors as in Example 1.

[0037] Table 3 Effects of high temperature sterilization treatment on volatile components and odor of corn juice

[0038]

[0039] As shown in Table 3, the sweet corn juice prepared by the blanching pretreatment method was sterilized at high temperature compared with dimethyl sulfide, hexanal, 2-pentyl furan, 1-pentanol in Example 2 The content of acetic acid and 2-acetylthiazole increased, and the increase of each component of the sample pretreated by adjusting the pH value, that is, treatment B, was lower than that of the sample pretreated by blanching. The odor analysis also showed that its odor was closer to that of Example 2, and the sterilized samples of the blanched pretreated sweet corn had a reduced sensory intensity of fresh and sweet flavor, which was closer to the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com