Method for measuring contents of silicon, manganese, phosphorus, molybdenum, copper, titanium, magnesium, lanthanum, cerium and yttrium in raw cast iron

A technology of silicon-manganese-phosphorus-molybdenum and copper-titanium is applied in the field of determining the content of silicon-manganese-phosphorus-molybdenum-copper-titanium-magnesium-lanthanum-cerium-yttrium in raw cast iron. It can solve the problems of high matrix element content, matrix effect, overlapping interference, etc., and achieve analysis speed Fast, short test time, and the effect of improving the lifting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1 Reagents and instruments

[0041] 1.1 Reagents

[0042] Concentrated nitric acid: ρ1.42g / mL, analytically pure, Yonghua Chemical Technology (Jiangsu) Co., Ltd.

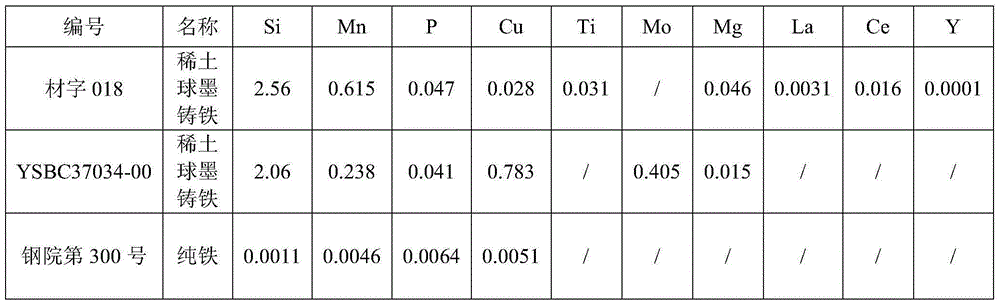

[0043]Standard samples: CAZ 018 Rare Earth Magnesium Ductile Iron, Shanghai Materials Research Institute; YSBC37034-00 Rare Earth Magnesium Ductile Iron, Zhengzhou Machinery Research Institute; Pure Iron No. 300: General Iron and Steel Research Institute. The chemical composition contents of the above standard samples are shown in Table 1 below.

[0044] Table 1

[0045]

[0046] Elements to be measured: Silicon: GSBG 62007-90(1401), 500μg / mL; Manganese: GSBG 62019-90(2502), 1000μg / mL; Phosphorus: GSBG 62009-90(1502), 1000μg / mL; Molybdenum: GSBG 62035 -90(4201), 1000μg / mL; Copper: GSBG62024-90(2902), 1000μg / mL; Magnesium: BSBG 62005-90(1201), 1000μg / mL; Titanium: GSBG 62014-90(2201), 1000μg / mL Lanthanum: GSBG 62047-90 (5701), 1000 μg / mL; Cerium: GSBG 62048-90 (5801), 1000 μg / mL; Yttrium: GSBG 62032-90 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com