Device for extracting residual saline matters from industrial waste residues

An extraction device and a technology for industrial waste residues, applied in the direction of alkali metal chlorides, etc., can solve the problems of reducing the recovery rate, slow dissolving speed, and increasing the recovery cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

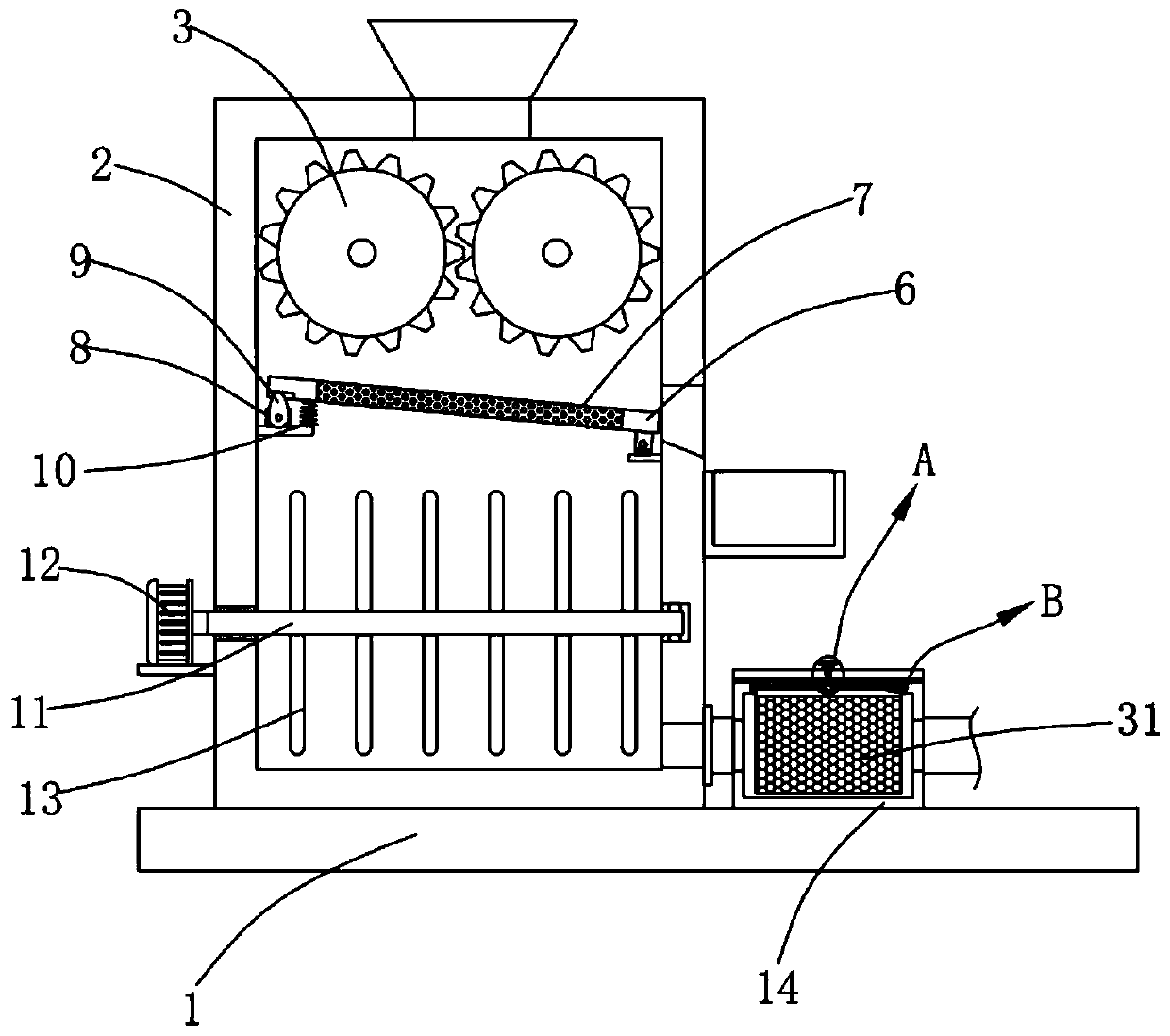

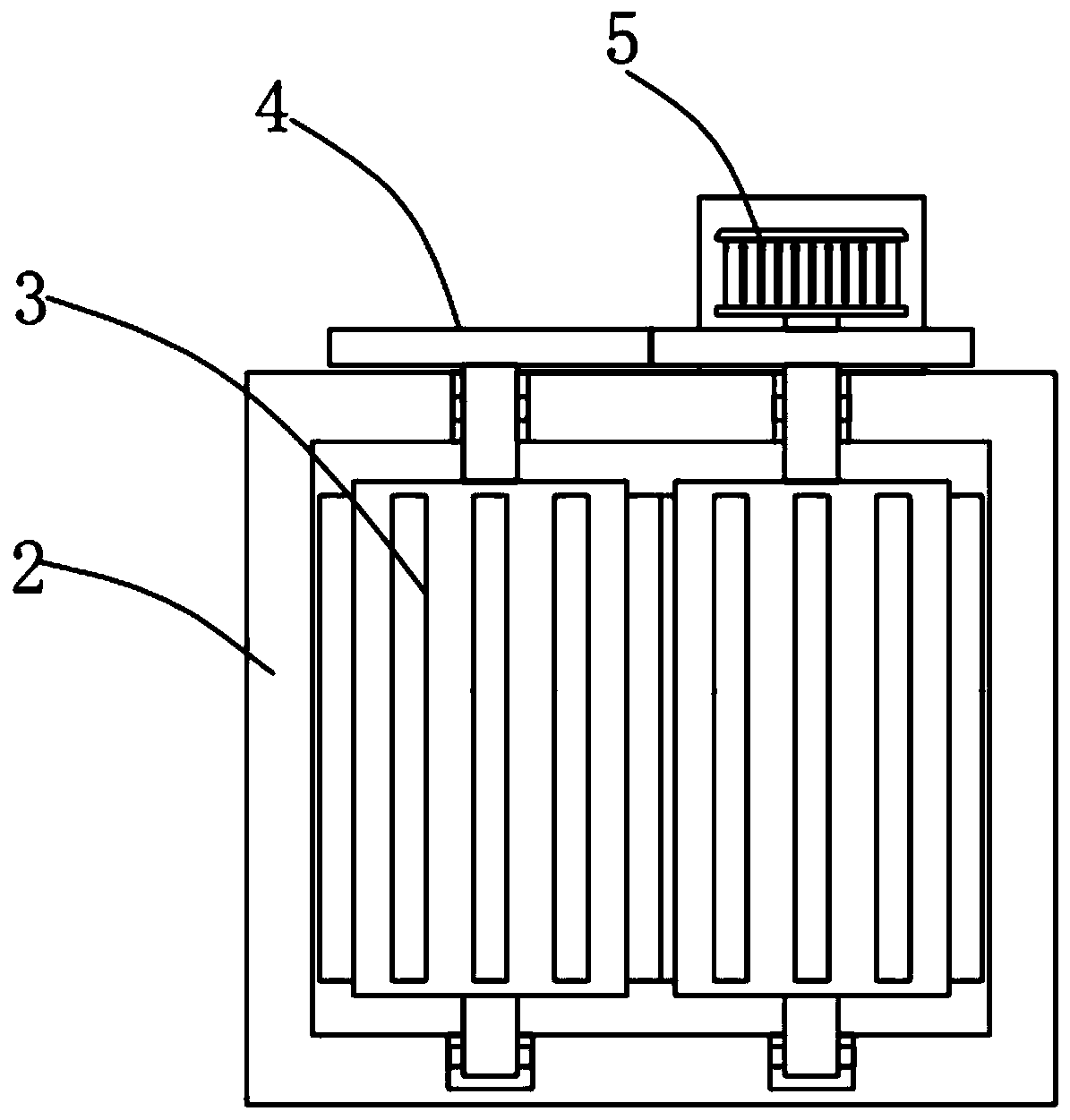

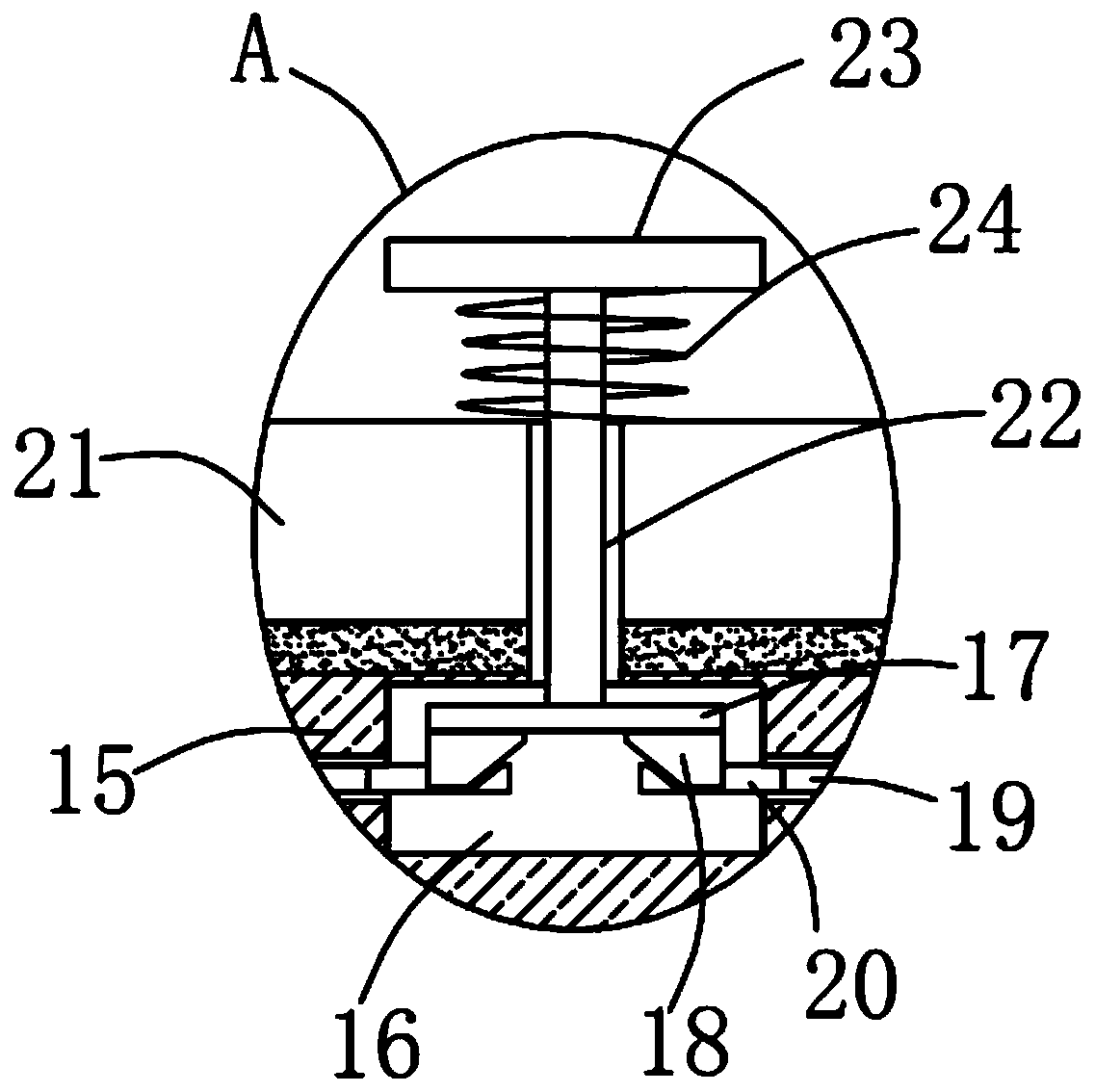

[0027] refer to Figure 1-5 , In this embodiment, an industrial waste residue residual salt extraction device is proposed, including a base 1, a casing 2 is fixedly installed on the top of the base 1, and two crushing rollers 3 are installed symmetrically in the casing 2. One end of the crushing roller 3 It extends to the outside of the casing 2 and is fixedly installed with a gear 4 , a first motor 5 is fixedly installed on one side of the casing 2 , the output shaft of the first motor 5 is fixedly connected with a gear 4 , and a screen is rotatably installed in the casing 2 Bracket 6, a screen mesh 7 is fixedly installed on the screen mesh support 6, a second motor 8 is fixedly installed in the housing 2, and a cam 9 is fixedly installed on the output shaft of the second motor 8, and the cam 9 is in contact with the mesh mesh support 6 , a first spring 10 is fixedly installed in the casing 2, the top of the first spring 10 is fixedly connected with the screen support 6, a ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com