Methacrylate macromonomer containing fluorine structure but not containing bisphenol A structure, preparation method therefor and application thereof

A technology of methacrylate and hydroxymethacrylate, which is applied in the field of methacrylate macromonomers, can solve problems affecting the growth and development of infants and young children, and question the safety of dental restoration materials, so as to promote photoinitiated polymerization, Reduce the effect of oxygen inhibition and reduce the shrinkage of polymerization volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

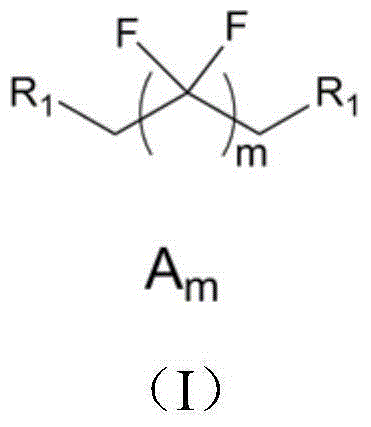

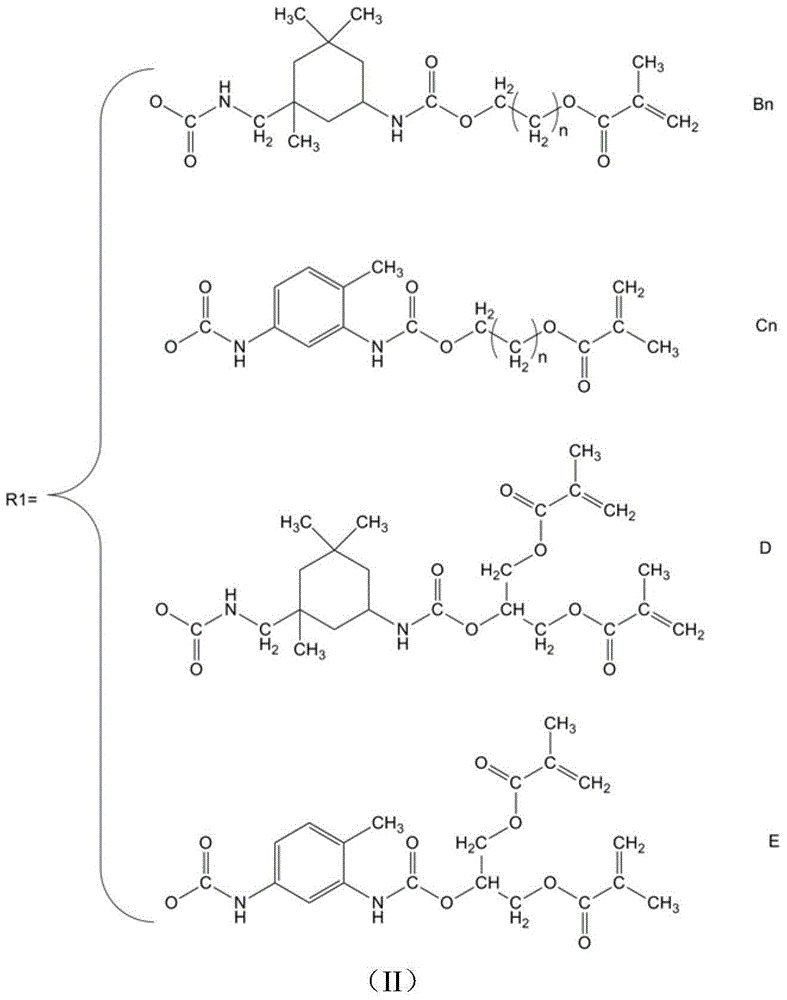

Method used

Image

Examples

Embodiment 1

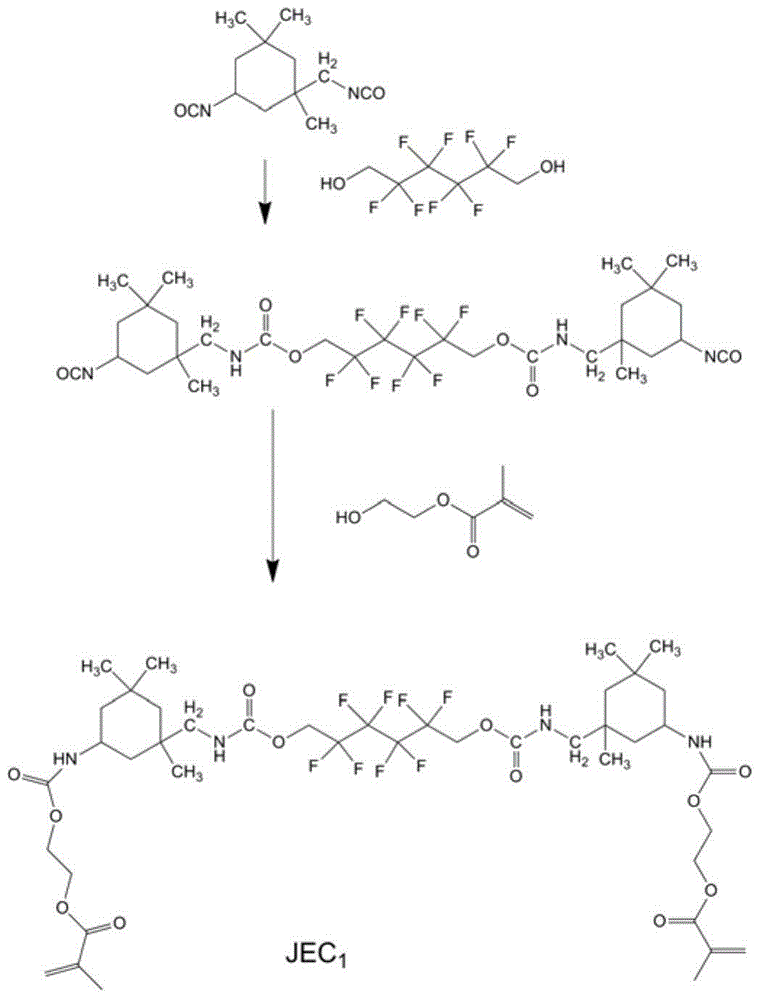

[0032] Preparation of DHOFH-IPDI-HEMA (A 4 B 1 ) large monomer:

[0033] The present embodiment DHOFH-IPDI-HEMA (A 4 B 1 ) The preparation method of macromer comprises the steps:

[0034] Add 6.67g of IPDI to a 250ml three-necked bottle equipped with a magnet, continuously add 3.93g of octafluoro-1,6-hexanediol (DHOFH) through a constant pressure dropping funnel under stirring, and rinse with 2g of tetrahydrofuran Constant pressure dropping funnel, react at 60°C for 0.5 hours, until the amount of -NCO in the diisocyanate system is consumed close to the theoretical value, adjust the temperature to 90°C in a water bath, and then add 3.91g to the reactor through the constant pressure dropping funnel Hydroxyethyl methacrylate (HEMA), 0.002g dibutyltin dilaurate and 0.11g hydroquinone were reacted, and the constant pressure dropping funnel was rinsed with tetrahydrofuran after adding the material, reacted for 2 hours, and then the reaction product was Purification treatment, y...

Embodiment 2

[0036] Preparation of DHOFH-IPDI-HEMA (A 4 B 1 ) large monomer

[0037] The present embodiment DHOFH-IPDI-HEMA (A 4 B 1 ) The preparation method of macromer comprises the steps:

[0038] Add 6.67g of IPDI to a 250ml three-necked bottle equipped with a magnet, and continuously add 3.93g of octafluoro-1,6-hexanediol (DHOFH) through a constant pressure dropping funnel under stirring, and use 2g of chloroform Rinse the constant pressure dropping funnel, react at 20°C for 10 hours, until the amount of NCO in the diisocyanate system is consumed close to the theoretical value, adjust the temperature to 40°C in a water bath, and then add to the reactor through the constant pressure dropping funnel 3.91g hydroxyethyl methacrylate (HEMA), 0.003g stannous octoate and 0.061g p-Hydroxyanisole are reacted, add the material and rinse the constant pressure dropping funnel with chloroform, react for 24 hours, then react the reaction product Purification treatment was carried out, and the ...

Embodiment 3

[0040] Preparation of DHOFH-TDI-HDMA (A 4 E) Large monomer

[0041] Add 17.4g of TDI to a 250ml three-neck bottle equipped with a magnet, and continuously add 13.1g of octafluoro-1,6-hexanediol (DHOFH) through a constant pressure dropping funnel under stirring, and rinse with 20mL of tetrahydrofuran Constant pressure dropping funnel, react at 60°C for 0.5 hours, until the amount of -NCO in the diisocyanate system is consumed close to the theoretical value, adjust the temperature to 45°C in a water bath, and then add 22.8g into the reactor through the constant pressure dropping funnel 2-Hydroxy-1,3-dimethylacryloyloxypropane (HDMA), 0.002g dibutyltin dilaurate and 0.11g hydroquinone were reacted, and the constant pressure dropping funnel was rinsed with tetrahydrofuran after adding the materials , reacted for 2 hours, and then purified the reaction product with a yield of 87%. FT-IR:ν(cm -1 ) 3335, 3068, 2950, 2923, 1720, 1636, 1608, 1585, 1242.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com