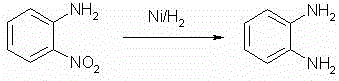

An improved synthetic method for preparing o-phenylenediamine by reduction of o-nitroaniline

A technology of o-nitroaniline and o-phenylenediamine, which is applied in the field of synthesis of o-phenylenediamine, can solve problems such as not considering alkali sulfide, potential safety hazards, and imperfect wastewater recovery process, so as to avoid potential safety hazards and pollution , reduce the risk of safety production, and the effect of efficient wastewater treatment capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

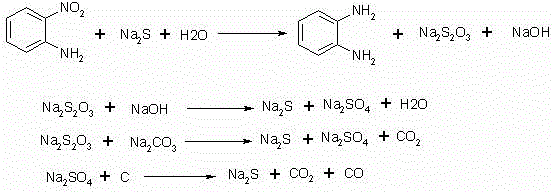

Embodiment 1

[0023] In a 20L reactor, put 2.5 kg of o-nitroaniline, 2.1 kg of sodium sulfide and 6.35 kg of water, mix well, control the temperature in the reactor between 96 and 102°C, reflux for 1 to 1.5 hours, and then Cooling, crystallization and filtration obtained 1.84 kg of crude o-phenylenediamine (the content of o-phenylenediamine was greater than 99.5% as detected by GC, and the yield was 94%). The filtrate was used as reaction waste liquid to recover sodium sulfide, and concentrated at a temperature range of 80-120 °C React the waste liquid, remove most of the water and some residual organic matter in the waste liquid, and obtain a solid residue, the main components are sodium thiosulfate, sodium hydroxide and a small amount of unreacted sodium sulfide, and the sulfur is mainly in the form of sodium thiosulfate exist. Mix the solid residue with 110g of sodium hydroxide evenly, send it into the furnace cavity of the electric furnace, set the heating temperature of the medium-temp...

Embodiment 2

[0025] In a 20L reactor, put 2.5 kg of o-nitroaniline, 2.5 kg of sodium sulfide and 10 kg of water, mix well, control the temperature in the reactor between 100 and 130°C, reflux for 3.5 hours, then cool and crystallize Filtrate to obtain 1.9 kg of crude product of o-phenylenediamine (the content of o-phenylenediamine detected by GC is greater than 99.3%, and the yield is 99.7%). The filtrate is used as reaction waste liquid to recover sodium sulfide, and the reaction waste is concentrated in the temperature range of 80-120°C. liquid, remove most of the water and part of the remaining organic matter in the waste liquid, and obtain a solid residue, the main components are sodium thiosulfate, sodium hydroxide and a small amount of unreacted sodium sulfide, and the sulfur mainly exists in the form of sodium thiosulfate. Mix the solid residue with 140g of sodium carbonate evenly, send it into the electric furnace chamber, set the heating temperature for medium-temperature calcinati...

Embodiment 3

[0027] In a 20L reactor, put 2.5 kg of o-nitroaniline, 2.1 kg of sodium sulfide and 8.3 kg of water, mix well, control the temperature in the reactor between 90 and 110°C, reflux for 2 hours, then cool and crystallize Filtrate to obtain 1.86 kg of crude product of o-phenylenediamine (the content of o-phenylenediamine detected by GC is greater than 99.3%, and the yield is 99.6%). The filtrate is used as reaction waste liquid to recover sodium sulfide, and the reaction waste is concentrated in the temperature range of 80-120°C. liquid, remove most of the water and part of the remaining organic matter in the waste liquid, and obtain a solid residue, the main components are sodium thiosulfate, sodium hydroxide and a small amount of unreacted sodium sulfide, and the sulfur mainly exists in the form of sodium thiosulfate. Mix the solid residue with 120g of sodium hydroxide evenly, send it into the furnace cavity of the electric furnace, set the heating temperature of the medium-tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com