Seepage-proofing leaking-stopping material and preparation method thereof

A technology for plugging materials and raw materials, which is applied in the field of anti-seepage plugging materials and their preparation, and can solve problems such as slurry being easily washed away by water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The raw materials of the anti-seepage and plugging material provided by the embodiments of the present invention are by weight percentage:

[0028] Sisal fiber 0.1%, gypsum 3%, alunite expansion agent 3.5%, cement 55%, water 38.4%.

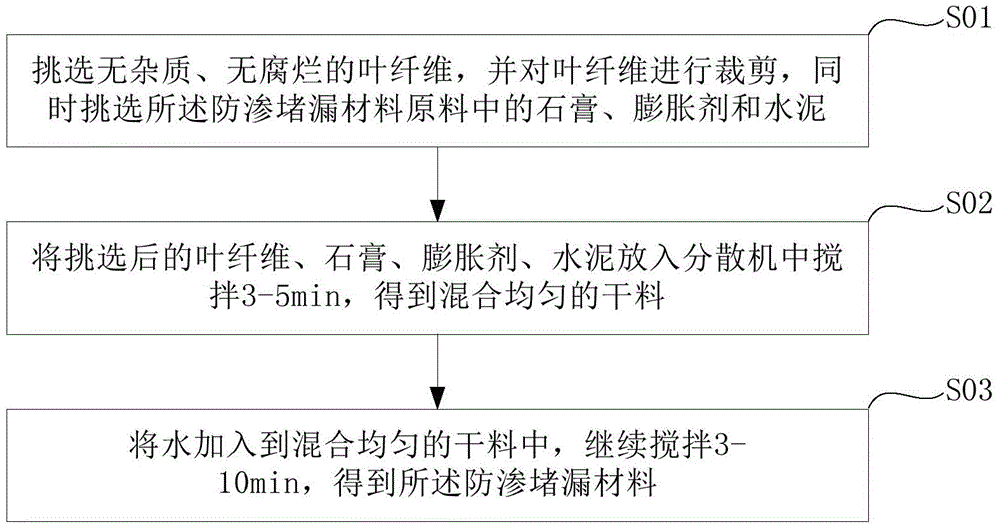

[0029] The preparation method of the anti-seepage plugging material provided by the embodiment of the present invention comprises the following steps:

[0030] S101: Select sisal fibers without impurities and rot, and cut the sisal fibers into short fibers of 10mm, and select powdered gypsum, alunite expansion agent and cement at the same time;

[0031] S102: Weigh the selected sisal fiber, powdery gypsum, alunite expansion agent and cement according to the above ratio, and put the weighed sisal fiber, powdery gypsum, alunite expansion agent and cement in the Stir in a disperser for 3 minutes to obtain a uniformly mixed dry material;

[0032] S103: Add the weighed water into the uniformly mixed dry material, and continue stirring for 3 mi...

Embodiment 2

[0034] The raw materials of the anti-seepage and plugging material provided by the embodiments of the present invention are by weight percentage:

[0035] Sisal fiber 0.25%, gypsum 5%, calcium sulfoaluminate expansion agent 3.5%, cement 40%, water 51.25%.

[0036] The preparation method of the anti-seepage plugging material provided by the embodiment of the present invention comprises the following steps:

[0037] S201: Select sisal fibers without impurities and rot, and cut the sisal fibers into short fibers of 12mm, and select powdered gypsum, calcium sulfoaluminate expansion agent and cement at the same time;

[0038] S202: Weigh the selected sisal fiber, powdery gypsum, calcium sulfoaluminate expansion agent and cement according to the above ratio, and expand the weighed sisal fiber, powdery gypsum, calcium sulfoaluminate Put the agent and cement into the disperser and stir for 5 minutes to obtain a uniformly mixed dry material;

[0039] S203: Add the weighed water into ...

Embodiment 3

[0041] The raw materials of the anti-seepage and plugging material provided by the embodiments of the present invention are by weight percentage:

[0042] Sisal fiber 0.25%, gypsum 8%, calcium oxide expansion agent 6%, cement 50.75%, water 35%.

[0043] The preparation method of the anti-seepage plugging material provided by the embodiment of the present invention comprises the following steps:

[0044] S301: Select sisal fibers without impurities and rot, and cut the sisal fibers into 15mm short fibers, and select powdered gypsum, calcium oxide expansion agent and cement at the same time;

[0045] S302: Weigh the selected sisal fiber, powdery gypsum, calcium oxide expansion agent and cement according to the above ratio, and put the weighed sisal fiber, powdery gypsum, calcium oxide expansion agent and cement in the Stir in a disperser for 4 minutes to obtain a uniformly mixed dry material;

[0046] S303: Add the weighed water into the uniformly mixed dry material, and conti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com