Automotive internal decorative plate composite material and production method thereof

A technology for automobile interior trim panels and composite materials, which is applied in the field of automobile interior trim panel composite materials and their production, can solve the problems of limited improvement of resin-based properties, difficult softening of hemp fibers, poor processability, etc., and achieves compressive strength and shear resistance. High shear strength, strong UV resistance, good high and low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

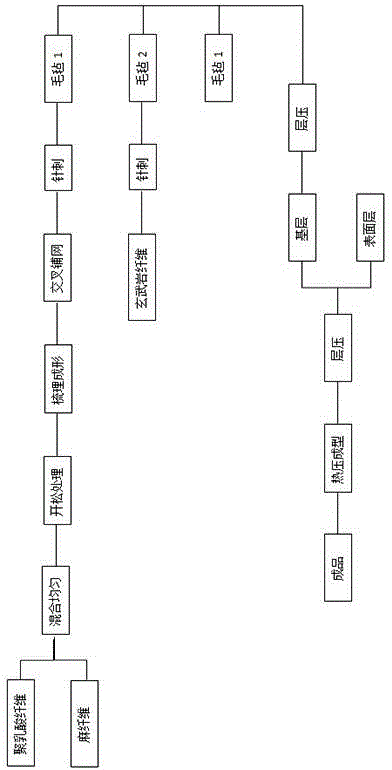

Image

Examples

Embodiment 1

[0020] Weigh the raw material (kg) according to the following weight:

[0021] Polylactic acid fiber 50, jute fiber 30, basalt fiber 20;

[0022] Method for producing automotive interior panels:

[0023] (1) 50kg length is 5~20cm polylactic acid fiber and 30kg length is 5~20cm jute fiber uniform mixing;

[0024] (2) put into the opening machine for opening treatment;

[0025] (3) transported to the carding machine by air flow for carding and forming;

[0026] (4) Send to the cross-lapping net in the net-laying machine;

[0027] (5) After the laid net is folded according to the requirements, it is sent to the pre-acupuncture machine for pre-acupuncture into felt;

[0028] (6) Continue to send the pre-acupunctured felt into the main needling machine for main needling to form the felt 1 composited with hemp fiber and polylactic acid fiber;

[0029] (7) 20kg basalt fiber is woven into felt 2;

[0030] (8) Lay and laminate together in the alternate order of felt 1, felt 2 and...

Embodiment 2

[0034] Weigh the raw material (kg) according to the following weight:

[0035] Polylactic acid fiber 50, sisal fiber 25, basalt fiber 25;

[0036] Method for producing automotive interior panels:

[0037] (1) 50kg length is the polylactic acid fiber of 5~20cm and the sisal fiber of 25kg length is 5~20cm and evenly mixes;

[0038] (2) put into the opening machine for opening treatment;

[0039] (3) transported to the carding machine by air flow for carding and forming;

[0040] (4) Send to the cross-lapping net in the net-laying machine;

[0041] (5) After the laid net is folded according to the requirements, it is sent to the pre-acupuncture machine for pre-acupuncture into felt;

[0042] (6) Continue to send the pre-acupunctured felt into the main needling machine for main needling to form the felt 1 composited with hemp fiber and polylactic acid fiber;

[0043] (7) 25kg basalt fiber is woven into felt 2;

[0044] (8) Lay and laminate together in the alternating order o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com