Coffee yogurt and preparation method thereof

A technology for coffee and yogurt, applied in the field of coffee yogurt and its preparation, can solve the problems of poor stability, influence on coffee flavor, and incongruity between coffee flavor and yogurt flavor, and achieves the advantages of reduced additive amount, good sensory enjoyment, and simple and feasible operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

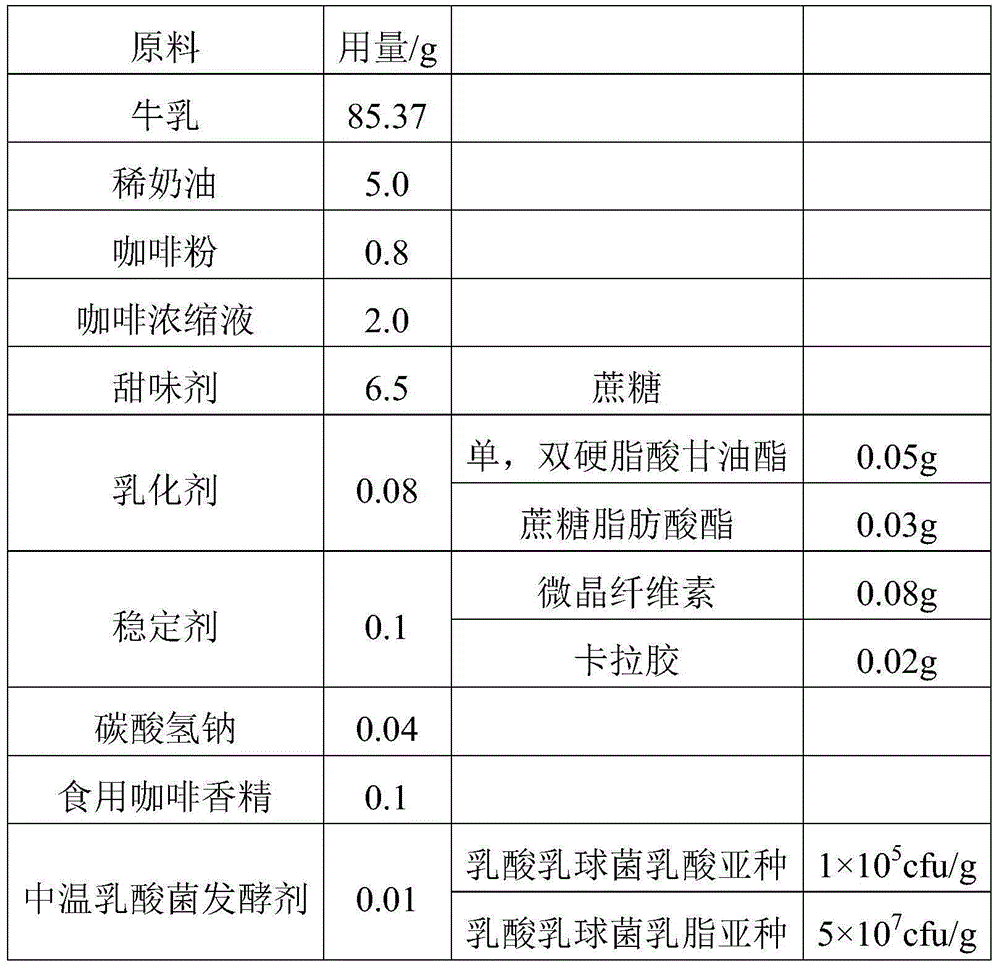

[0040] formula:

[0041]

[0042] The process steps are as follows:

[0043] 1. Heat milk to 60°C, add cream, coffee powder, coffee concentrate, sucrose, mono- and distearic acid glycerides, sucrose fatty acid esters, carrageenan, microcrystalline cellulose and sodium bicarbonate, stir to dissolve After heat preservation for 15min, material A was obtained;

[0044] 2. After homogenizing the material A obtained in step 1 at 60°C and 25Mpa, pasteurize at 85°C for 15s to obtain a fermentation substrate;

[0045] 3. Cool down the fermentation substrate obtained in step 2 to 35°C, add medium-temperature lactic acid bacteria starter at 35°C to ferment until the final acidity is 80°T, cool to 16°C, add edible coffee essence, stir evenly, fill and refrigerate at 10°C.

Embodiment 2

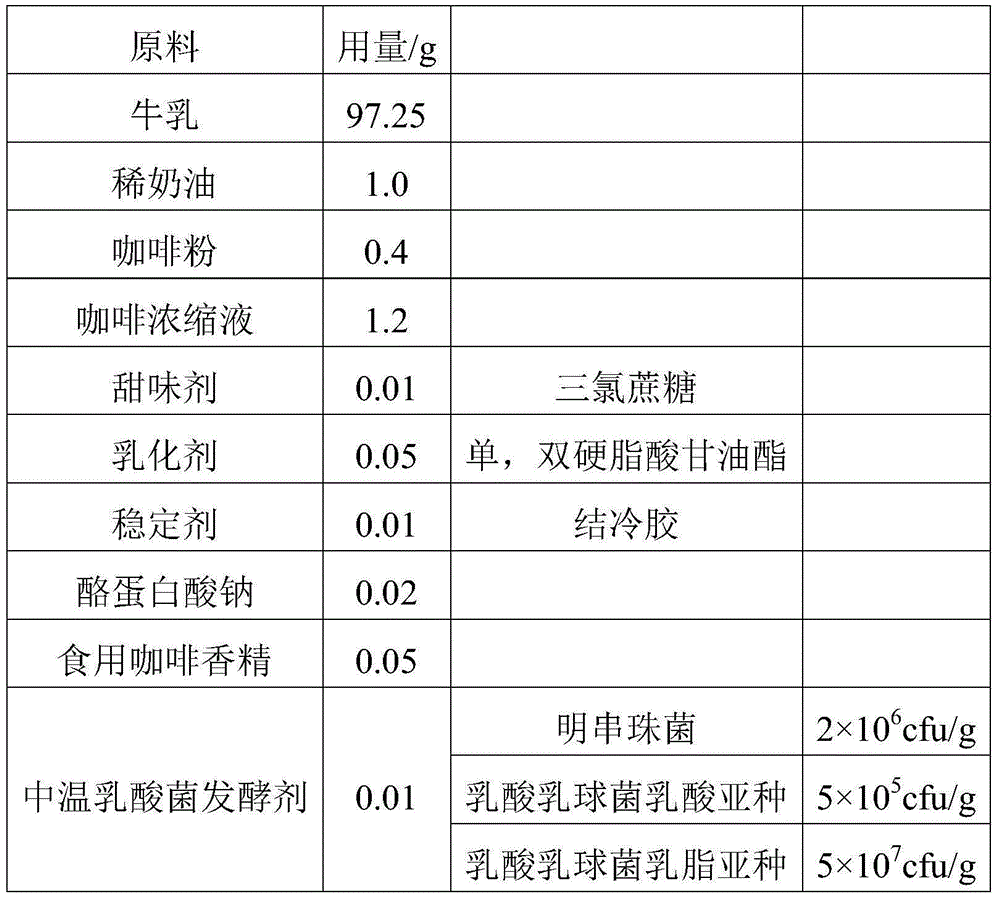

[0047] formula:

[0048]

[0049] The process steps are as follows:

[0050] 1. Heat the milk to 40°C, add cream, coffee powder, coffee concentrate, sucralose, glyceryl mono- and distearate, gellan gum and sodium caseinate, stir and dissolve and keep warm for 30 minutes to obtain the material A;

[0051] 2. After homogenizing the material A obtained in step 1 at 65°C and 25Mpa, pasteurize at 85°C for 15s to obtain a fermentation substrate;

[0052] 3. Cool down the fermentation substrate obtained in step 2 to 38°C, add medium-temperature lactic acid bacteria starter to ferment at 38°C until the final acidity is 80°T, cool to 16°C, add edible coffee essence, stir evenly, fill and refrigerate at 4°C.

Embodiment 3

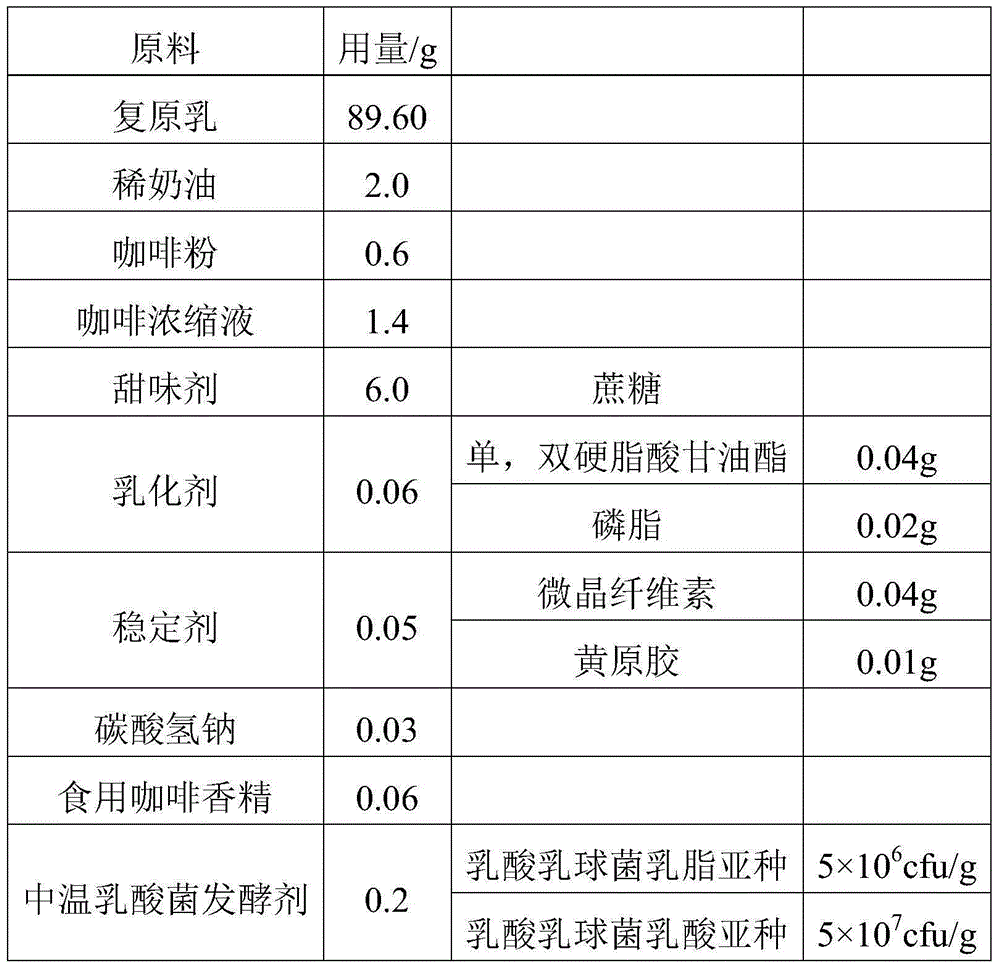

[0054] formula:

[0055]

[0056] Wherein, the preparation method of the reconstituted milk is: add 150kg of whole milk powder into 850L of water until completely dissolved.

[0057] The process steps are as follows:

[0058] 1. Heat the reconstituted milk to 50°C, add cream, coffee powder, coffee concentrate, sucrose, mono- and distearin glycerides, phospholipids, microcrystalline cellulose, xanthan gum and sodium bicarbonate, stir to dissolve Heat preservation for 20 minutes to obtain material A;

[0059] 2. After homogenizing the material A obtained in step 1 at 60°C and 25Mpa, pasteurize at 85°C for 15s to obtain a fermentation substrate;

[0060] 3. Cool down the fermentation substrate obtained in step 2 to 38°C, add medium-temperature lactic acid bacteria starter to ferment at 37°C until the final acidity is 70°T, cool to 20°C, add edible coffee essence, stir evenly, fill and refrigerate at 4°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com