A kind of preparation method of composite yarn

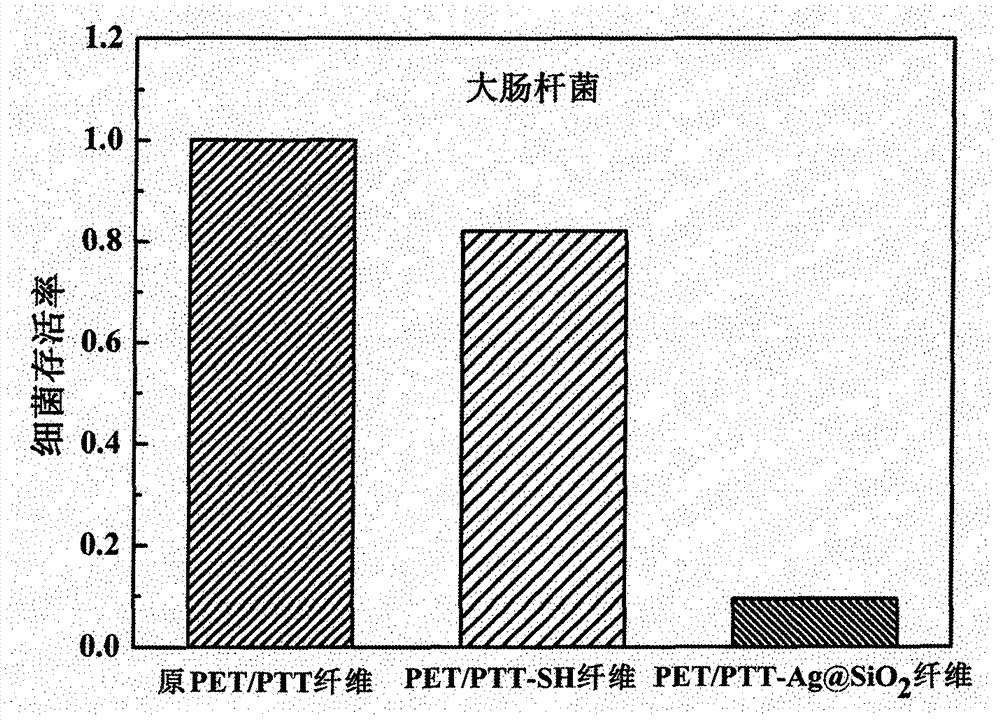

A yarn and composite fiber technology, which is applied in the field of composite yarn preparation, can solve the problems of unsatisfactory air permeability and sweat absorption of fabrics, low service life of clothes, poor elasticity and wear resistance, etc., and achieves excellent bulkiness, Excellent antibacterial and soft touch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

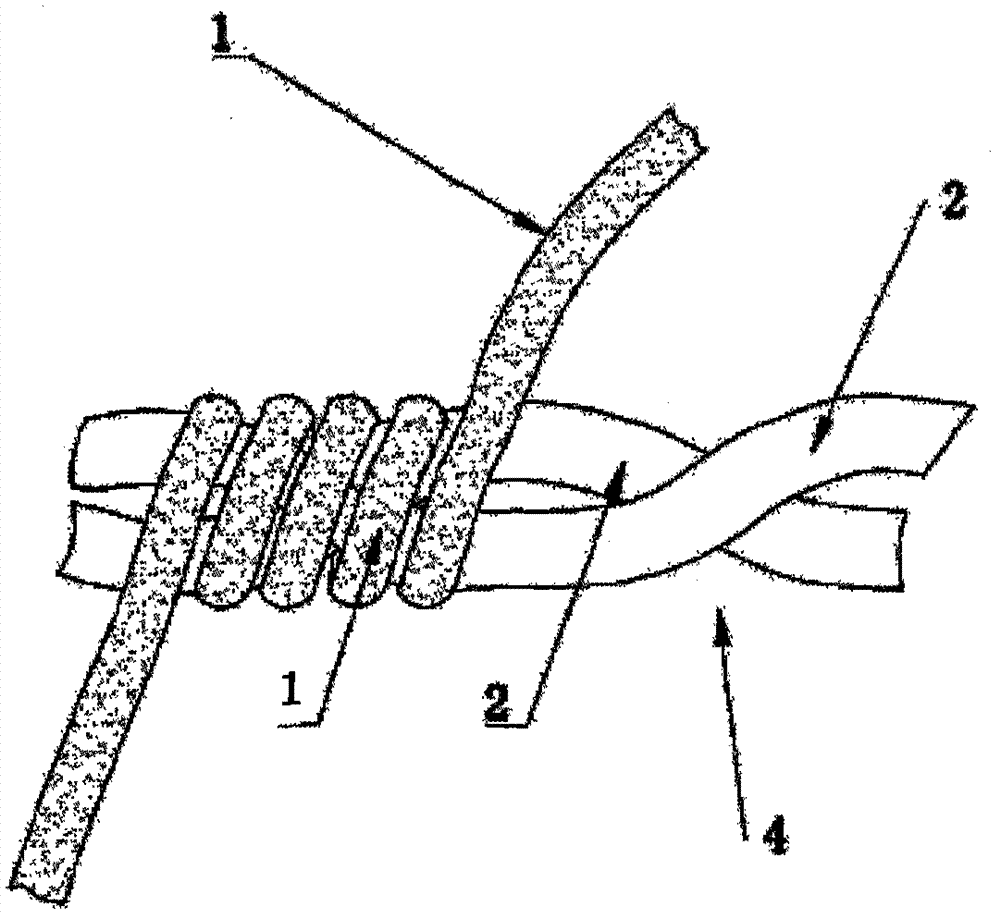

[0023] The embodiment of the present invention discloses a preparation method of a composite yarn, comprising the following steps: providing a polyester yarn core formed by a PET / PTT composite fiber; immersing the artificial fiber in a toluene solution of glycidyl methacrylate (GMA), Fix PGMA on the surface of the rayon by interfacial polymerization, and then graft cysteamine on the surface of the rayon; soak the rayon grafted with cysteamine on the surface for 1-5 hours in the antibacterial mother solution, wash and dry to obtain an antibacterial The artificial fiber outer sliver, the antibacterial mother solution includes titanium dioxide particles, nano-silver particles and hydrochloric acid aqueous solution; the artificial fiber outer sliver is spirally wound on the polyester yarn core to obtain a composite yarn.

[0024] As a preferred solution, the PET / PTT composite fiber is prepared according to the following method: polyethylene terephthalate (PET) and polytrimethylene ...

Embodiment 1

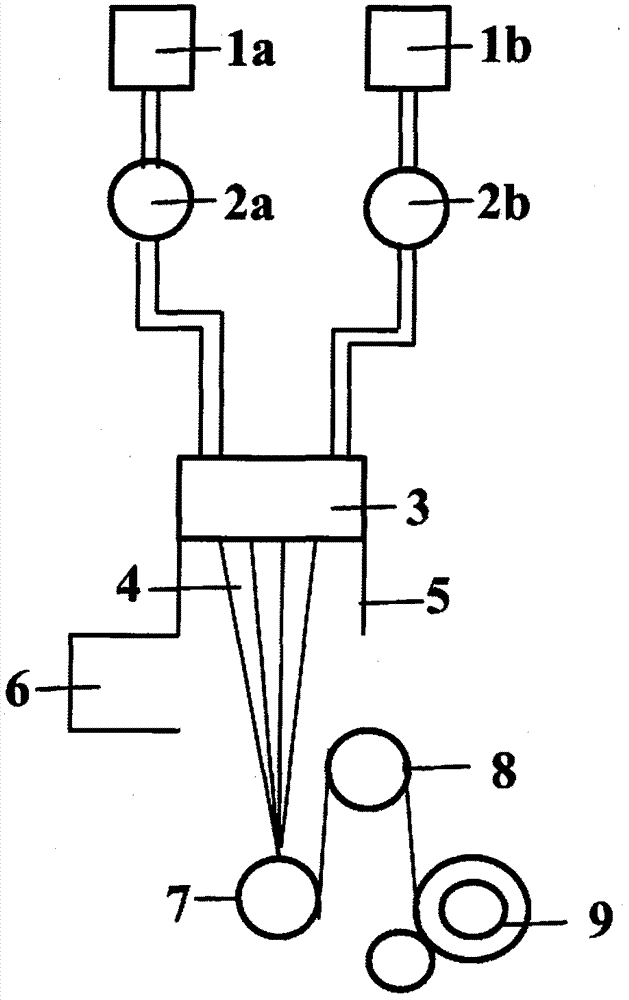

[0040] Such as figure 2 As shown, the pre-dried PET and PTT were placed in two melters 1a and 1b according to the ratio of 7:3 in parts by mass and heated and melted, and the temperature was set at 230°C. 2b Feed into the composite spinneret 3, the composite filament 4 that is extruded and spun passes through the stable windless zone 5, and contacts with the condensed air ejected from the cooling window 6, and the cooled filament 4 is wound to the winding roller. On the driven bobbin 9, winding yarn is formed, and a pair of guide rollers 7 and 8 are used to adjust the tension to obtain bicomponent polyester fibers, namely PET / PTT composite fibers.

[0041] The extrusion speeds of the metering pumps are all 45 rpm, and the outer diameter of the composite filament is about 0.12 mm.

[0042] Two PET / PTT composite fibers prepared above were twisted forward to form a polyester yarn core.

[0043] Dissolve 8wt% of the GMA monomer together with the initiator azobisisobutyronitrile...

Embodiment 2

[0049] Such as figure 2 As shown, the pre-dried PET and PTT were placed in two melters 1a and 1b according to the ratio of 7:3 in parts by mass and heated and melted, and the temperature was set at 245°C. 2b Feed into the composite spinneret 3, the composite filament 4 that is extruded and spun passes through the stable windless zone 5, and contacts with the condensed air ejected from the cooling window 6, and the cooled filament 4 is wound to the winding roller. On the driven bobbin 9, winding yarn is formed, and a pair of guide rollers 7 and 8 are used to adjust the tension to obtain bicomponent polyester fibers, namely PET / PTT composite fibers.

[0050] The extrusion speeds of the metering pumps are all 65 rpm, and the outer diameter of the composite filament is about 0.12 mm.

[0051] Two PET / PTT composite fibers prepared above were twisted forward to form a polyester yarn core.

[0052] Dissolve 11wt% of the GMA monomer together with the initiator azobisisoheptanonitri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com