Waste emulsion quantitative reduction processing technology and apparatus

A waste emulsion and treatment process technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It is obvious that it is difficult to automate operation, etc., to achieve the effect of obvious reduction effect, easy automatic control, and convenient automatic control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

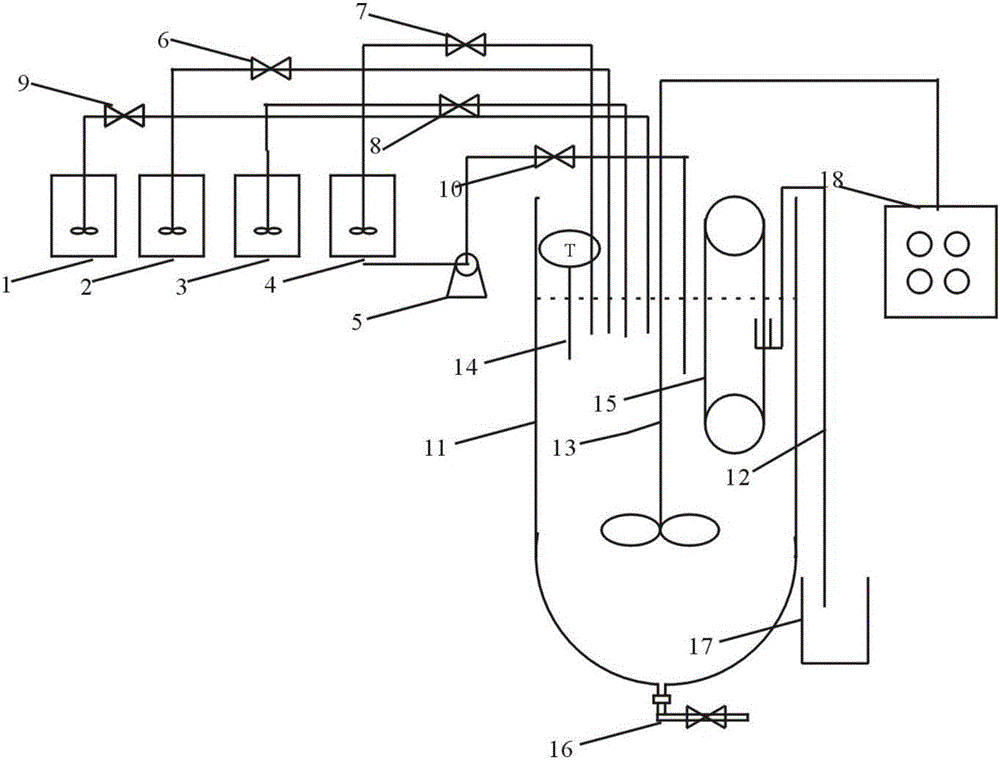

[0036] The waste emulsion enters the waste emulsion reduction device container 11 through the waste emulsion lifting pump 5, and the switch of the lifting pump 5 is controlled by the program set in the liquid level float controller and the electric control cabinet 18, thereby controlling the flow of the waste emulsion. Measure the amount of waste emulsion water inflow through the water inlet electromagnetic flowmeter 10, and turn on the stainless steel stirring device 12 at the same time. Sulfuric acid is added, and the sulfuric acid metering pump 7 is programmed according to the program in the electrical control cabinet 18 and the pH and temperature compound electrodes 14 to control the dosage of sulfuric acid. After the addition of sulfuric acid, the stainless steel agitator 13 is turned on, and an appropriate stirring program is set in the electrical control cabinet 18 according to the characteristics of the emulsion. With oil skimmer 15 for oil skimming treatment, the proc...

Embodiment 2

[0039] A Taiwan-funded electrical treatment company produces 1m3 / d of waste emulsion, and the treatment cost is 3800 yuan / m3. After adopting the device of the present invention, the dosage of sulfuric acid is between 0.8% and 1.5%, the diameter of the steel strip oil skimmer is 25 mm, the volume after oil skimming is reduced to less than 90% of the original volume, and the operation time of the steel strip oil skimmer is 12 hours. The operating cost is 100 yuan / m3, which saves the owner 3320 yuan / day in operating costs and provides great economic value for the owner. The test results show that the influent COD concentration is 160,000mg / L, the oil concentration is 100,000mg / L, the effluent COD concentration is less than 20,000mg / L, and the oil removal rate is higher than 98%. Add 5000mg / L of ferrous sulfate and 15000mg / L of hydrogen peroxide to the effluent (using the Fenton oxidation system formed by ferrous ions and hydrogen peroxide to minimize the organic matter in the was...

Embodiment 3

[0041] A German Transmission Machinery Co., Ltd. produces 3m3 / d of waste emulsion. After adopting this device, the volume ratio of sulfuric acid is 1.2%, the operation time of steel belt oil skimmer is 16h, and the COD concentration of waste emulsion is 100000mg / L. After treatment, the COD of the effluent is less than 10000mg / L. Dosing hydrogen peroxide 15000mg / L and ferrous sulfate 5000mg / L in the effluent, the COD concentration after treatment is less than 8500mg / L, and the supernatant is mixed with domestic sewage and cleaning wastewater for treatment. After treatment, the COD is less than 60mg / L to achieve wastewater reuse Require.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com