Mesoporous magnesium silicate/ hydroxyapatite/ polyether-ether-ketone composite material, bone restoration and preparation method and application thereof

A technology of hydroxyapatite and polyetheretherketone, which is applied in the field of materials, can solve the problems of looseness, poor mechanical compatibility, and inability to bond firmly to bone repair materials, and achieves accelerated bone healing, good biological activity and biological Compatibility, effect on shortening bone healing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] A preparation method of mesoporous magnesium silicate, comprising the steps of:

[0066] (1) Mix 8.5g of P123, 240mL of deionized water and 8g of absolute ethanol, and stir until the solution is clear, then add 20mL of hydrochloric acid with a concentration of 11.9mol / L at 40°C and stir to mix, then add 24g of TEOS Add dropwise into the solution, stir until the solution becomes white and turbid, then add 29.5g of magnesium nitrate hexahydrate, and continue stirring for 2.5h to obtain a reaction solution;

[0067] (2) Aging the reaction solution at 98°C for 48 hours, then removing the supernatant by suction filtration, drying the precipitate at 85°C, and sintering at 600°C for 7 hours to obtain mesoporous magnesium silicate.

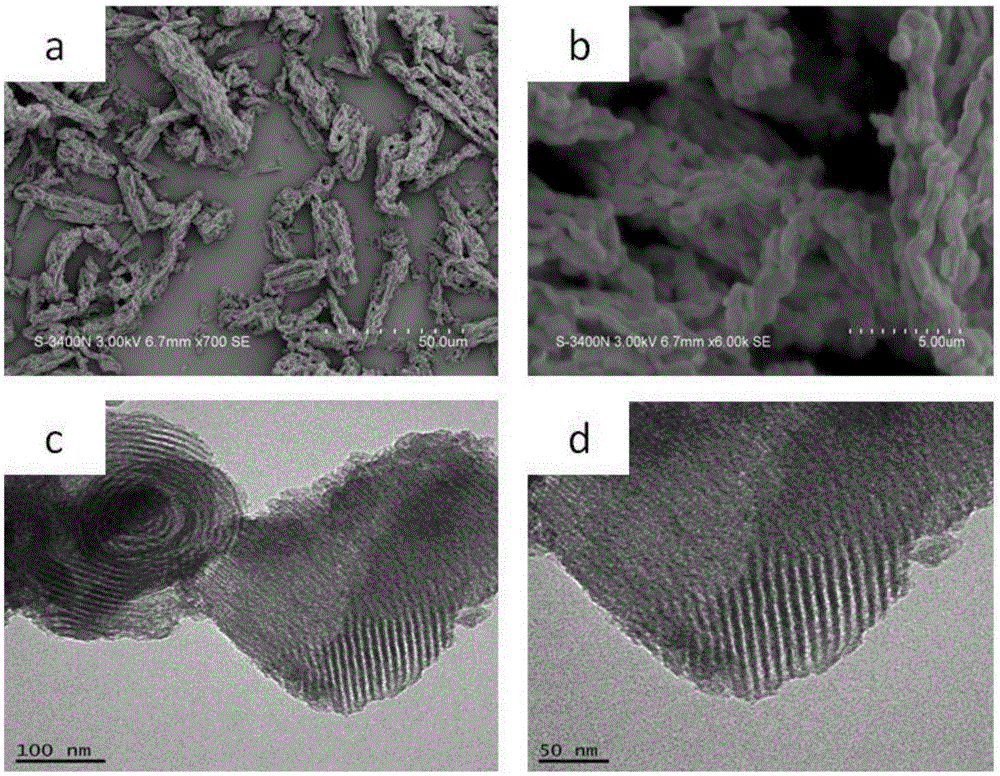

[0068] The scanning electron micrographs and transmission electron micrographs of the mesoporous magnesium silicate / hydroxyapatite are shown in figure 1 (a), (b) and figure 1 (c), (d); the mesoporous magnesium silicate / hydroxyapatite has a mesopo...

Embodiment 2

[0070] The preparation method of mesoporous magnesium silicate / hydroxyapatite / polyether ether ketone composite material, it comprises the following steps:

[0071] Put 2kg (20wt%) of the mesoporous magnesium silicate prepared in Example 1, 1.5kg (15wt%) of hydroxyapatite and 6.5kg (65wt%) of polyether ether ketone (particle size is 10 μm) in a mixer Mix evenly to obtain a mixed powder; mix the mixed powder with absolute ethanol, disperse it ultrasonically for 30 minutes at a power of 60W, and then place it in an oven at 65°C to evaporate the absolute ethanol; product mold), and then heated up in a sintering furnace, sintered and formed, and obtained; wherein, the sintering temperature is 350 ° C; the heating rate of the sintering furnace is 1 ° C / min; the holding time is 140 min. The mechanical properties of the mesoporous magnesium silicate / hydroxyapatite / polyether ether ketone composite are shown in Table 1.

Embodiment 3

[0073] A method for preparing a bone prosthesis, comprising the steps of:

[0074] 1.5kg (15wt%) of the mesoporous magnesium silicate prepared in Example 1, 1.5kg (15wt%) of hydroxyapatite powder and 7kg (70wt%) of polyetheretherketone (particle size is 15 μm) were mixed in a mixer Mix the raw materials uniformly in the medium to obtain a mixed powder; mix the mixed powder with absolute ethanol, disperse it ultrasonically for 30 minutes with a power of 70W, and then place it in an oven at 70°C to evaporate the absolute ethanol to obtain a composite powder; then press the composite powder with a mold Molding (the mold of the bone prosthetic product), and then heating up in a sintering furnace, sintering and molding, and the obtained; wherein, the sintering temperature is 360°C; the heating rate of the sintering furnace is 1°C / min; the holding time is 140min. The mechanical properties of the bone restoration are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com