High-quality gate oxide forming method

A gate oxide layer, high-quality technology, applied in the SiCoN dry etching process, gate oxide layer formation technology, high-quality gate oxide layer formation field, can solve the problems of native oxide layer growth, etc., to improve product performance, improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

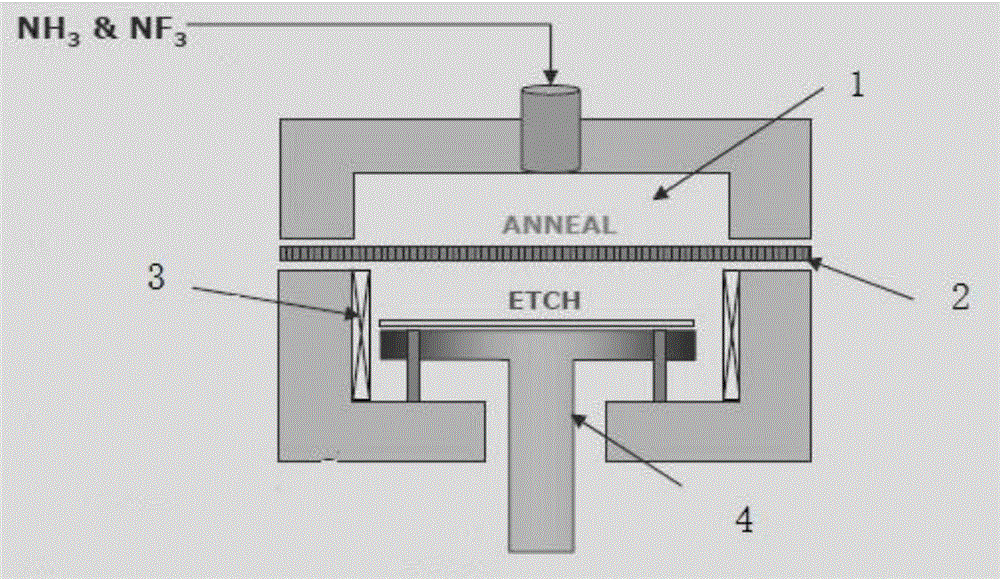

[0040] The specific embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

[0041] It should be noted that the technical solution proposed by the present invention is the same as the prior art, using SiCoNi to remove the native silicon oxide layer on the silicon surface or the residual silicon oxide layer from the previous process, which is different from the prior art However, it only needs the etching step in the SiCoNi process, and does not need to use high temperature to remove the (NH4) on the silicon surface. 2 SiF 6 Layer volatilized, but keep this layer (NH4) 2 SiF 6 , Making it a protective layer on the silicon surface to prevent the formation of native silicon oxide. Has (NH4) 2 SiF 6 After the protective film wafer goes to the high-temperature oxidation furnace, during the heating process of the oxidation furnace, (NH4) 2 SiF 6 It will be completely decomposed and volatilized, so it will not affect th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com