Preparation method for polyimide composite material for automobile

A polyimide and composite material technology, which is applied in the field of preparing polyimide composite materials for automobiles, can solve the problems of insufficient environmental protection, high cost of raw materials, low degradability, etc., so as to save production costs and improve surface roughness. , the effect of enhancing lipophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

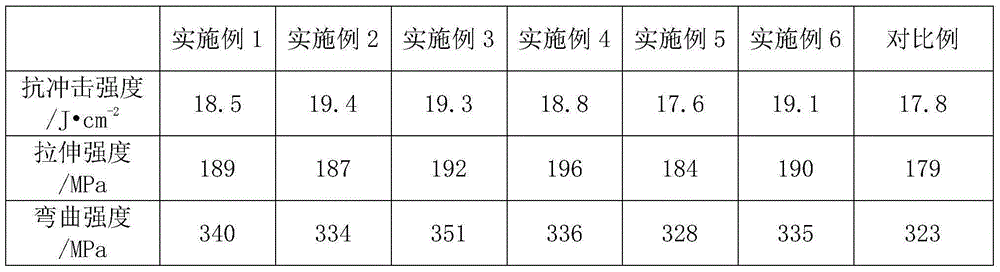

Examples

Embodiment 1

[0024] A kind of preparation method of polyimide composite material for automobile, its steps are as follows:

[0025] (1) Dry the sisal fiber after removing impurities, add the dried sisal fiber to the sodium hydroxide solution with a concentration of 72g / L and soak for 10 hours, take it out and wash it with dilute acid solution 3 times to obtain alkalized Sisal fiber is also dried, KH550 is dissolved in the acetic acid solution and stirred for 3 hours, wherein, the pH value of the acetic acid solution is 5.5, the acetic acid solution pH value of KH550 is adjusted to 7 with the ammoniacal liquor of 6% by mass fraction, let stand After 2 hours, the treatment solution was obtained. Add the dried alkalized sisal fiber into the treatment solution for ultrasonic dispersion for 3 hours, take it out and put it in a vacuum drying oven for 3 hours at 120°C to dry it for 3 hours, take it out, break it up, and pulverize it to get Modified sisal fiber for standby;

[0026] (2) Add talc ...

Embodiment 2

[0029] A kind of preparation method of polyimide composite material for automobile, its steps are as follows:

[0030] (1) Dry the sisal fiber after removing impurities, add the dried sisal fiber to the sodium hydroxide solution with a concentration of 72g / L and soak for 10 hours, take it out and wash it with dilute acid solution 3 times to obtain alkalized Sisal fiber is also dried, KH550 is dissolved in the acetic acid solution and stirred for 3 hours, wherein, the pH value of the acetic acid solution is 5.5, the acetic acid solution pH value of KH550 is adjusted to 7 with the ammoniacal liquor of 6% by mass fraction, let stand After 2 hours, the treatment solution was obtained. Add the dried alkalized sisal fiber into the treatment solution for ultrasonic dispersion for 3 hours, take it out and put it in a vacuum drying oven for 3 hours at 120°C to dry it for 3 hours, take it out, break it up, and pulverize it to get Modified sisal fiber for standby;

[0031] (2) Add talc ...

Embodiment 3

[0034] A kind of preparation method of polyimide composite material for automobile, its steps are as follows:

[0035] (1) Dry the sisal fiber after removing impurities, add the dried sisal fiber to the sodium hydroxide solution with a concentration of 72g / L and soak for 10 hours, take it out and wash it with dilute acid solution 3 times to obtain alkalized Sisal fiber is also dried, KH550 is dissolved in the acetic acid solution and stirred for 3 hours, wherein, the pH value of the acetic acid solution is 5.5, the acetic acid solution pH value of KH550 is adjusted to 7 with the ammoniacal liquor of 6% by mass fraction, let stand After 2 hours, the treatment solution was obtained. Add the dried alkalized sisal fiber into the treatment solution for ultrasonic dispersion for 3 hours, take it out and put it in a vacuum drying oven for 3 hours at 120°C to dry it for 3 hours, take it out, break it up, and pulverize it to get Modified sisal fiber for standby;

[0036] (2) Add talc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com