Spraying-repairing method for ceramic sanitary ware glaze

A technology for sanitary ware and glazed surfaces, applied in the field of gunning repairing defects, which can solve problems such as low efficiency, high cost, and long time-consuming, and achieve good visual effects, good acid resistance, and consistent visual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

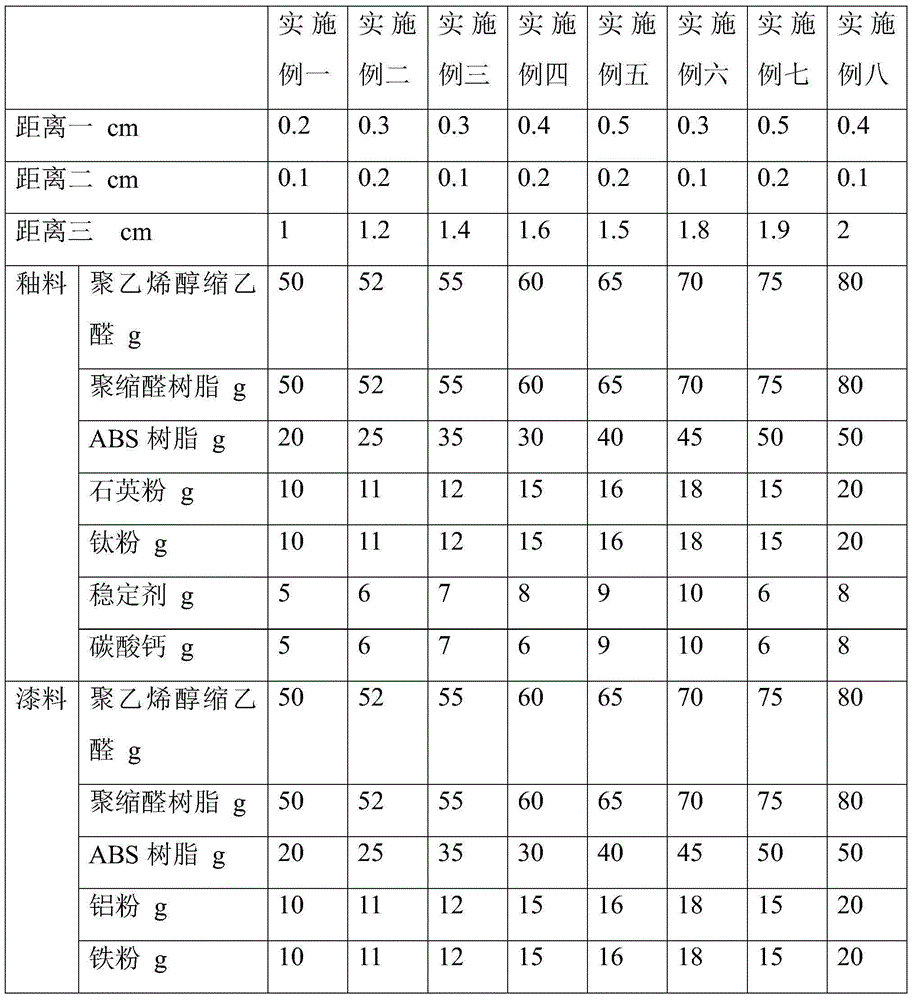

[0029] 1. Grinding: use a grinder to grind the defective parts on the surface of the sanitary ware, and the distance between the outer edge of the polished area and the outer edge of the defective part of the sanitary ware is 0.3cm;

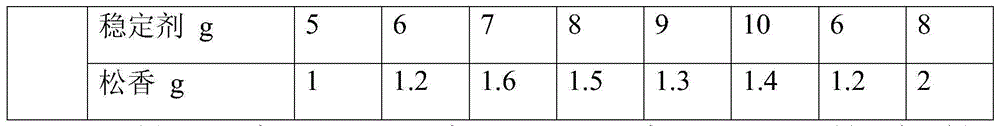

[0030] 2. Glaze repair: Take a diaphragm with waterproof effect, cut a through hole in the center of the diaphragm, the shape and area of the through hole are consistent with the shape and area that need to be polished at the defect, and the edge of the through hole of the diaphragm is consistent with the periphery of the diaphragm. The distance between the edges is 1.4cm. Cover the defect of the sanitary ware with the diaphragm, and then apply the glaze on the defect of the sanitary ware. The distance between the outer edge of the glaze area and the outer edge of the defect of the sanitary ware is 0.1cm; The components of the material and their mass parts ratio are: 55 parts of polyvinyl acetal, 55 parts of polyacetal resin, 30 parts of ABS res...

Embodiment 1

[0033] Embodiment 1, embodiment 2, embodiment 4, embodiment 5, its operation method is consistent with embodiment 3, difference only lies in the parameter in table 1.

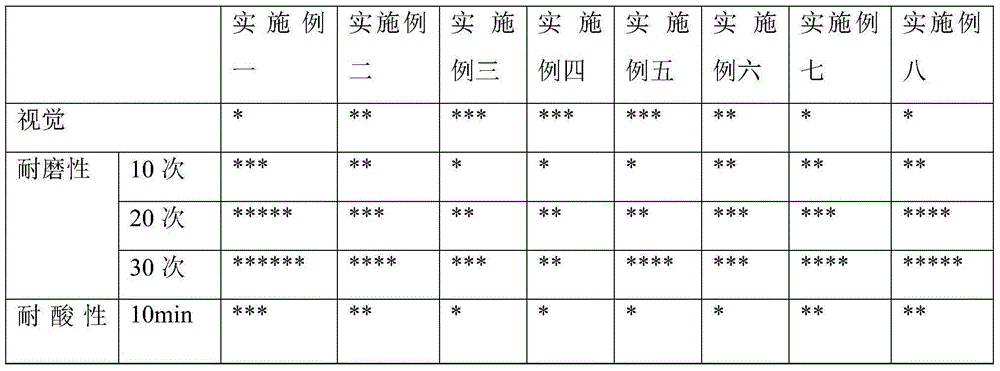

[0034] The following experiments prove the visual effects, wear resistance, acid and alkali resistance and aging properties of the sanitary ware repaired by the operation method of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com