Cutting depth self-adjusting mechanism and drill bit

A cutting depth, self-adjusting technology, used in drill bits, earthwork drilling, drilling equipment, etc., can solve problems such as low drilling efficiency, stick-slip vibration, etc., to overcome the fixed cutting depth, prevent damage and twist break, The effect of expanding the stable operating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

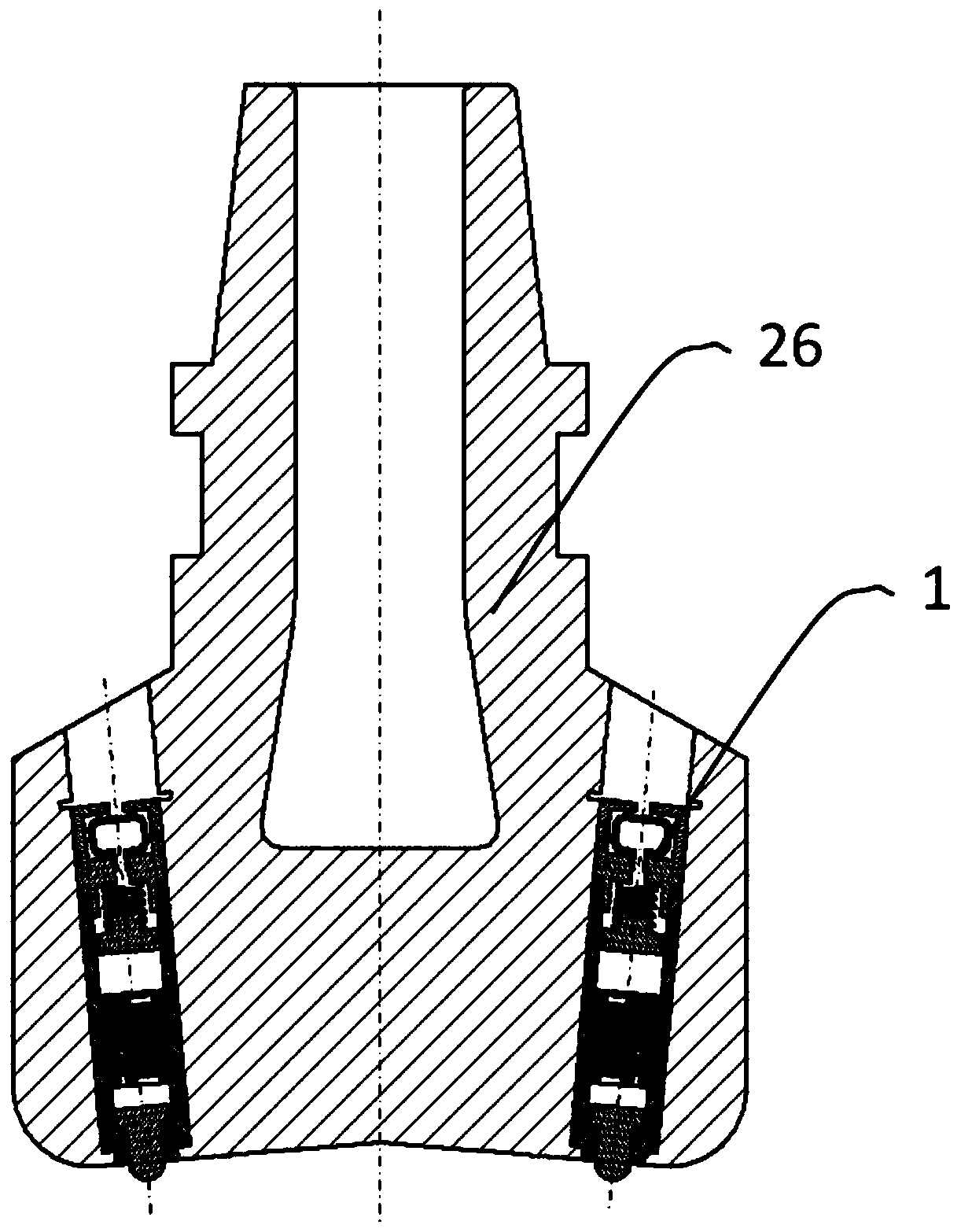

[0035] Please refer to figure 1 , with reference to figure 2 , the embodiment of the present application provides a drill bit 26, the blades on both sides of the drill bit 26 are respectively symmetrically installed with a cutting depth self-adjusting mechanism 1, which is mainly used for adjusting the cutting depth of the drill bit 26, and can effectively prevent the drill bit 26 from stick-slip In the case of vibration, the combination between the cutting teeth of the drill bit 26 and the bottom hole can be protected, the footage of the drill bit 26 can be extended, and the safety of drilling construction can be improved, thereby effectively improving the efficiency and benefit of drilling construction.

[0036] It should be noted that, in this embodiment, the drill bit 26 may be a PDC drill bit.

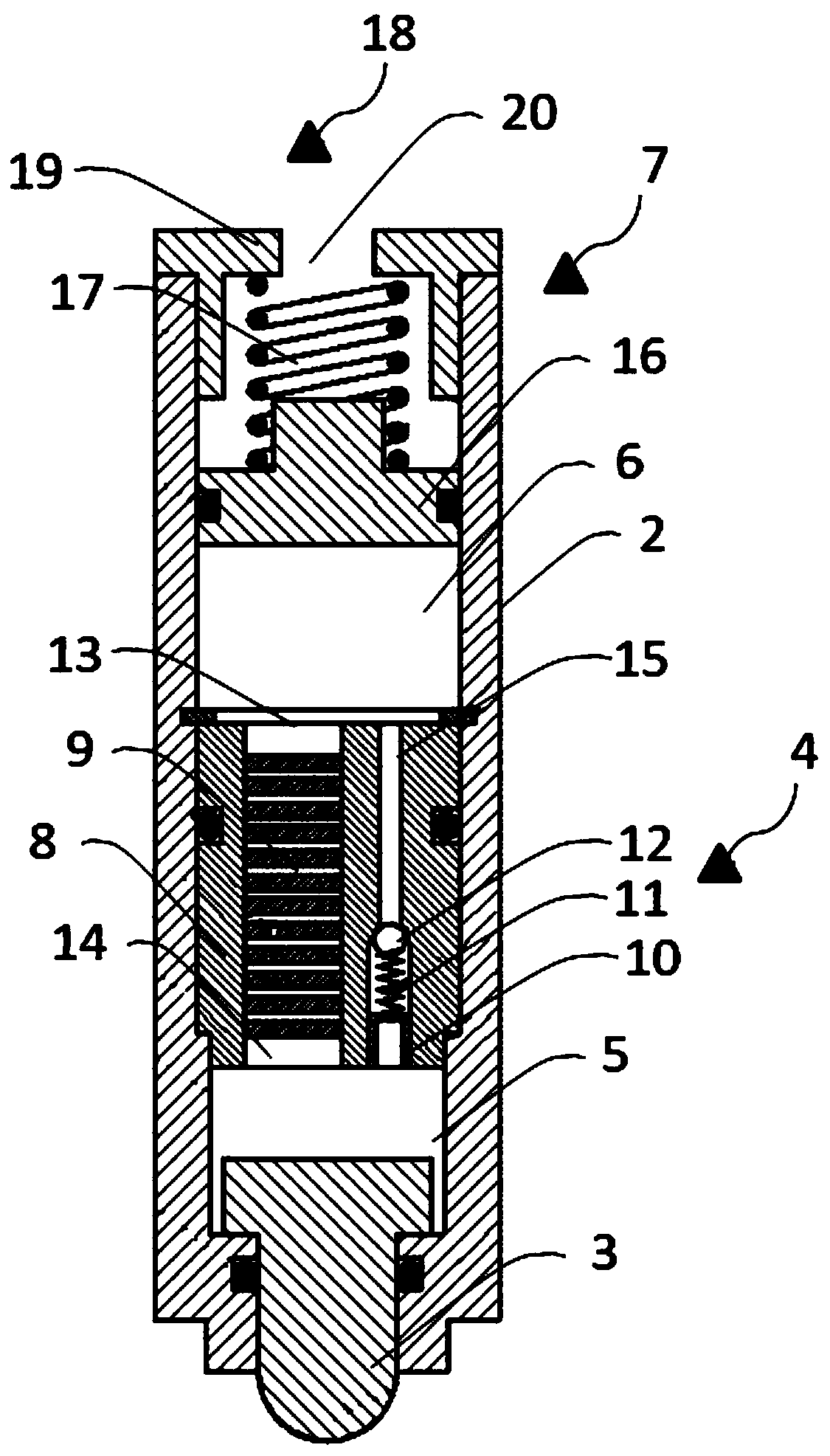

[0037] Please refer to figure 2The cutting depth self-adjusting mechanism 1 mainly includes an outer cylinder 2, a ball tooth 3, a throttling damping valve 4 and a hydraulic r...

no. 2 example

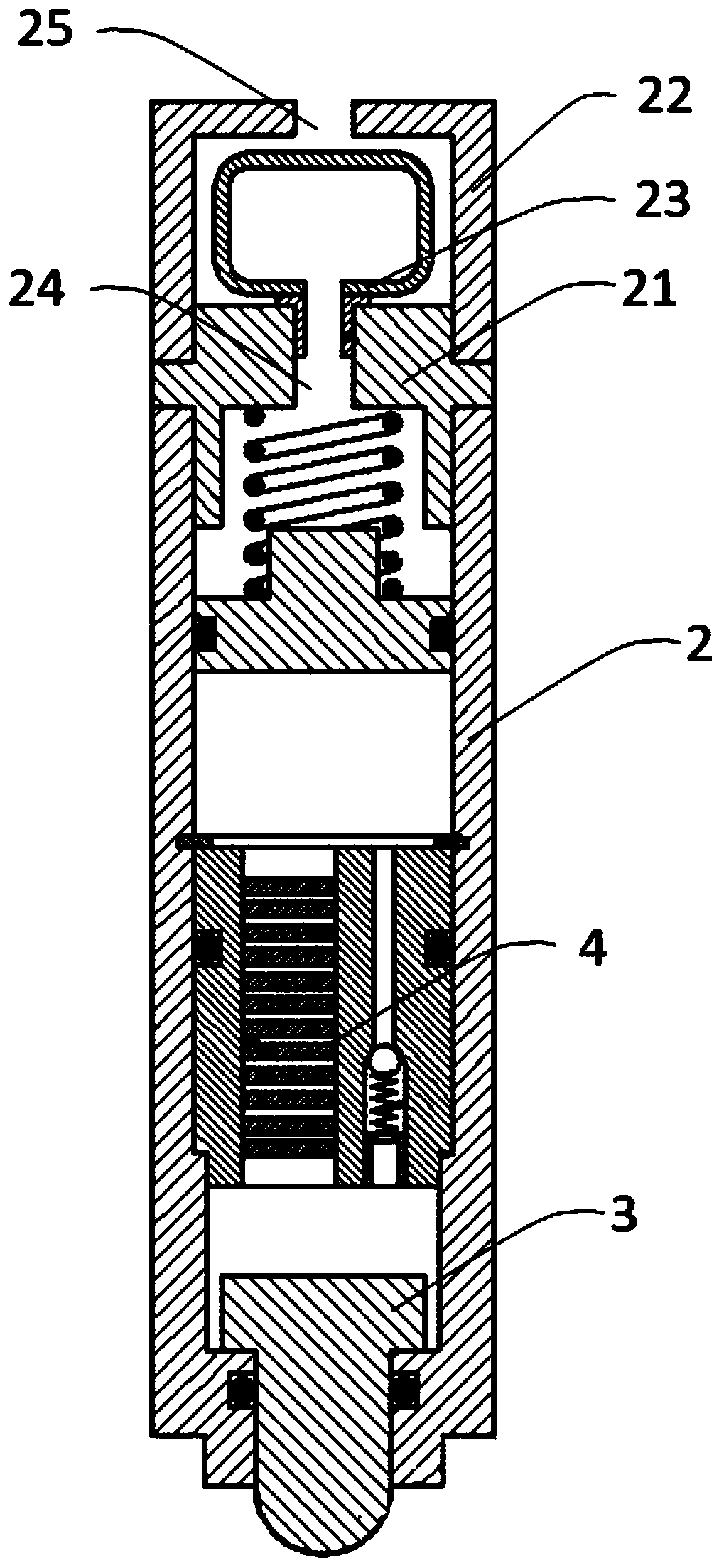

[0056] Please refer to image 3 , the embodiment of the present application provides another structure of the cutting depth self-adjusting mechanism 1 and the drill bit 26, most of its structure is the same as that of the first embodiment, the difference is that the protection structure 18 in the present application is different from that in the first embodiment is different.

[0057] It should be noted that, in this embodiment, the protective structure 18 includes a mounting cover 21, a protective cover 22 and a rubber bladder 23; the mounting cover 21 is mounted on the other end of the outer cylinder 2, and the mounting cover 21 is provided with a second opening 24 , the other end of the return spring 17 is crimped on the mounting cover 21; the protective cover 22 is set on the mounting cover 21 through a threaded connection cover, and the protective cover 22 is provided with a third opening 25; the rubber bladder 23 is arranged in the protective cover 22 , and connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com