Method and system for preparing carbonyl iron powder by utilizing red mud

A technology of carbonyl iron powder and carbonyl iron, which is applied to the removal of carbonyl iron and solid waste, can solve the problems of low utilization rate and long-term storage of industrial waste, and achieve effective utilization, long-term storage and utilization low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

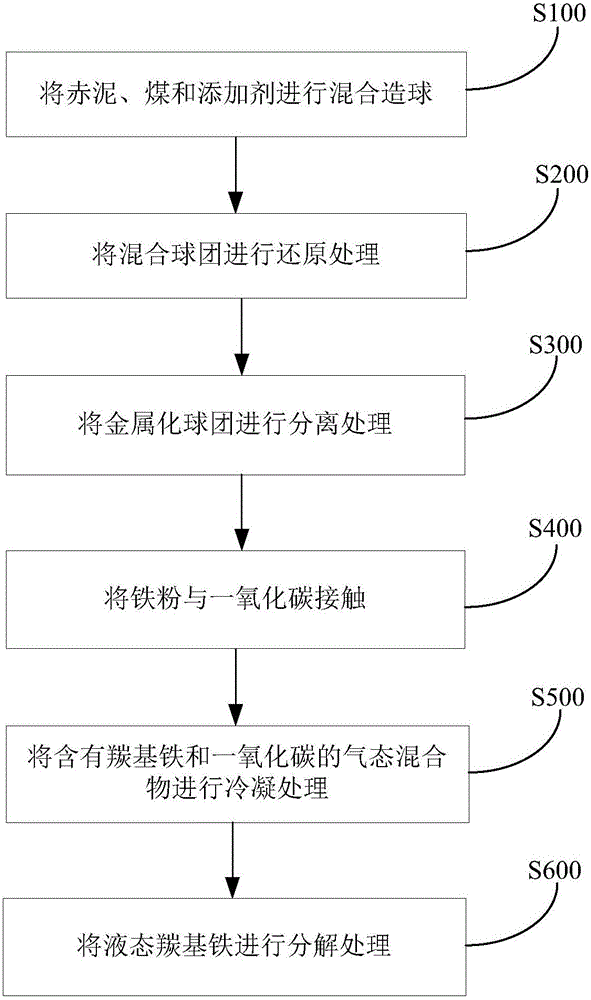

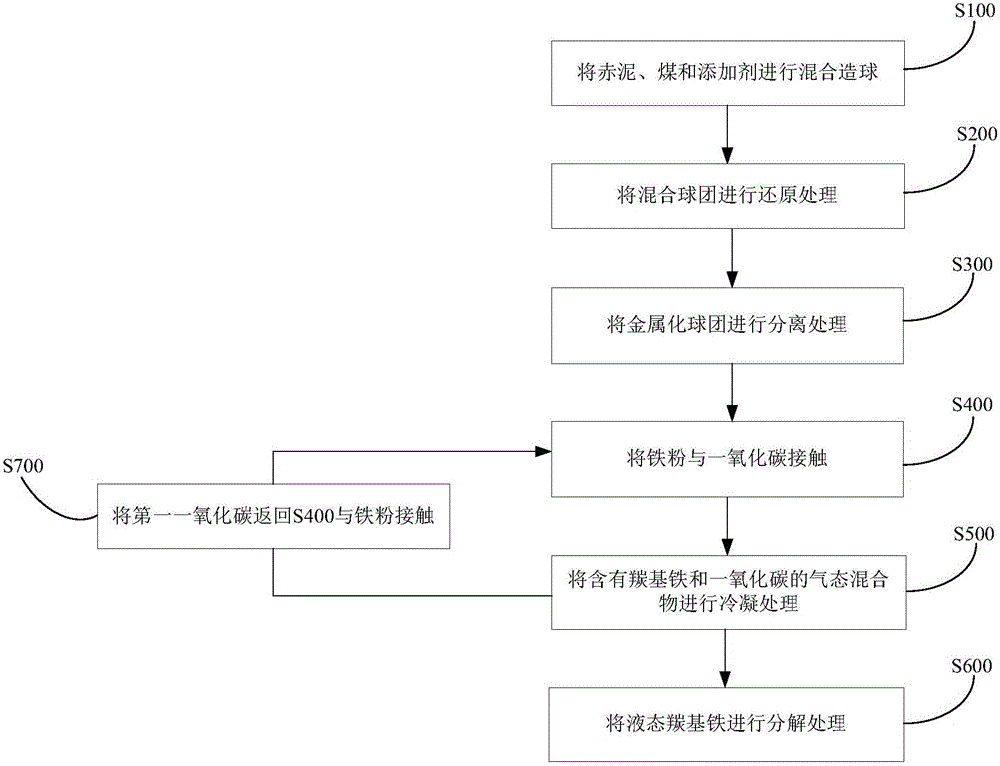

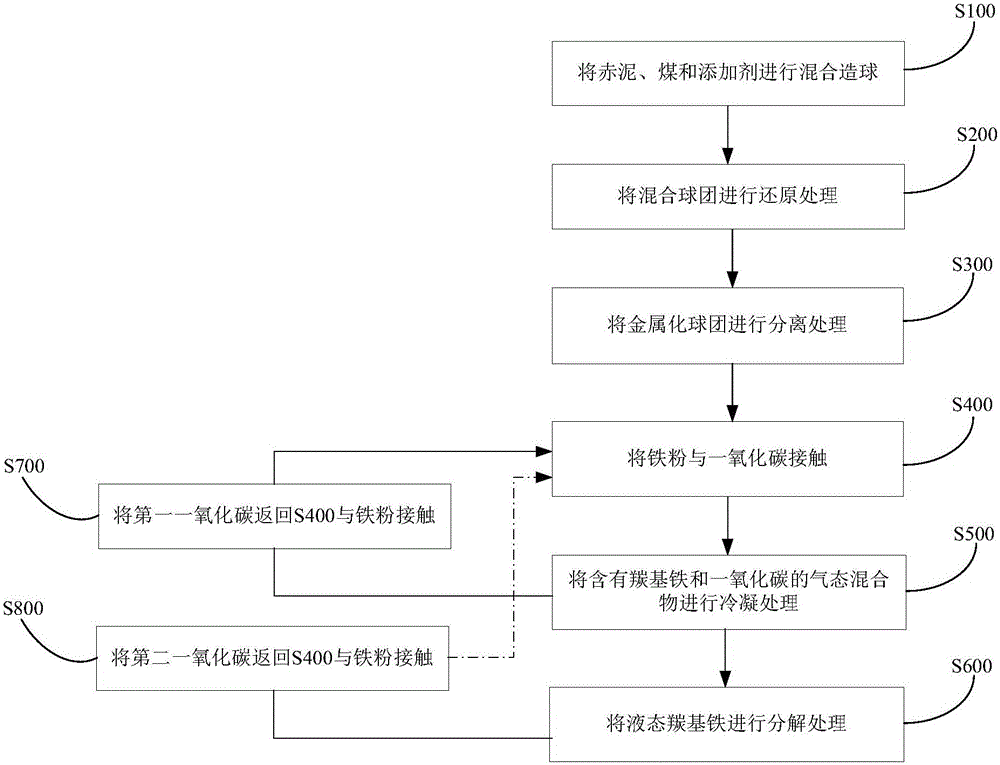

Method used

Image

Examples

Embodiment 1

[0089] Red mud, coal, and calcium oxide are mixed evenly and then pelletized and dried. The mixing mass ratio of red mud, coal, and calcium oxide is 100:25:10, and the dried mixed pellets are reduced at 1220°C to obtain Metallized pellets (the metallization rate is 92wt%, and the surface of the pellets shows a slight melting phenomenon), and then the obtained metallized pellets are separated by crushing, grinding and magnetic separation to obtain iron powder with an average particle size of less than 74 microns. Then, the iron powder is contacted with CO countercurrently to generate a carbonylation reaction to generate a gaseous mixture containing carbonyl iron and carbon monoxide, and the gaseous mixture containing carbonyl iron gas and carbon monoxide is condensed to obtain liquid carbonyl iron and carbon monoxide, and the carbon monoxide is returned to contact with the iron powder The reaction is continued, and finally the obtained liquid carbonyl iron is vaporized and then ...

Embodiment 2

[0091] Mix red mud, coal, and limestone and then make pellets and dry them. The mixing mass ratio of red mud, coal, and limestone is 100:35:15. The dried mixed pellets are reduced at 1250°C to obtain metallized pellets. Pellets (90.5wt% metallization rate, micro-melting on the surface of the pellets), and then the metallized pellets are separated through crushing, grinding and magnetic separation to obtain iron powder with an average particle size lower than 74 microns, and then The iron powder is contacted with CO countercurrently to generate a carbonylation reaction to form a gaseous mixture containing carbonyl iron and carbon monoxide, and then condense the gaseous mixture containing carbonyl iron gas and carbon monoxide to obtain liquid carbonyl iron and carbon monoxide, and return the carbon monoxide to contact with the iron powder to continue reaction, and finally gasify the obtained liquid carbonyl iron and then decompose it to obtain carbonyl iron powder with an iron gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com