Sheet alpha-Al2O3 powder body with controllable particle diameter size and preparation method of sheet alpha-Al2O3 powder body

A flaky, particle size technology, applied in the field of fillers and ceramic composite materials, can solve the problems of not preparing particle size, not studying the amount of seed crystal addition, and rarely considering the effect of size, etc., to achieve the effect of particle size control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In the first step, dissolve 112.0g Al in 300ml deionized water 2 (SO4) 3 18H 2 O, 28g γ-Al 2 o 3 , 57.6gNa 2 SO 4 and 47.2gK 2 SO 4 (The molar ratio of soluble salts to aluminum sulfate is 4:1), then add 2.7g flake α-Al 2 o 3 Seed crystal (equivalent to 6% of the final alumina quality, purchased from Hebei Oak Fine Chemical Co., Ltd.), flake α-Al 2 o 3 The average particle size of the seed crystals is 2.80±0.22um, and the mixture is stirred for 15 minutes to obtain a uniform solution M.

[0037] In the second step, 54 g of sodium carbonate was dissolved in 150 ml of deionized water to obtain N solution. Afterwards, under the action of stirring, the solution N was slowly dropped into the M solution, and the pH of the solution was controlled to be 9 to obtain a mixed aluminum hydroxide gel.

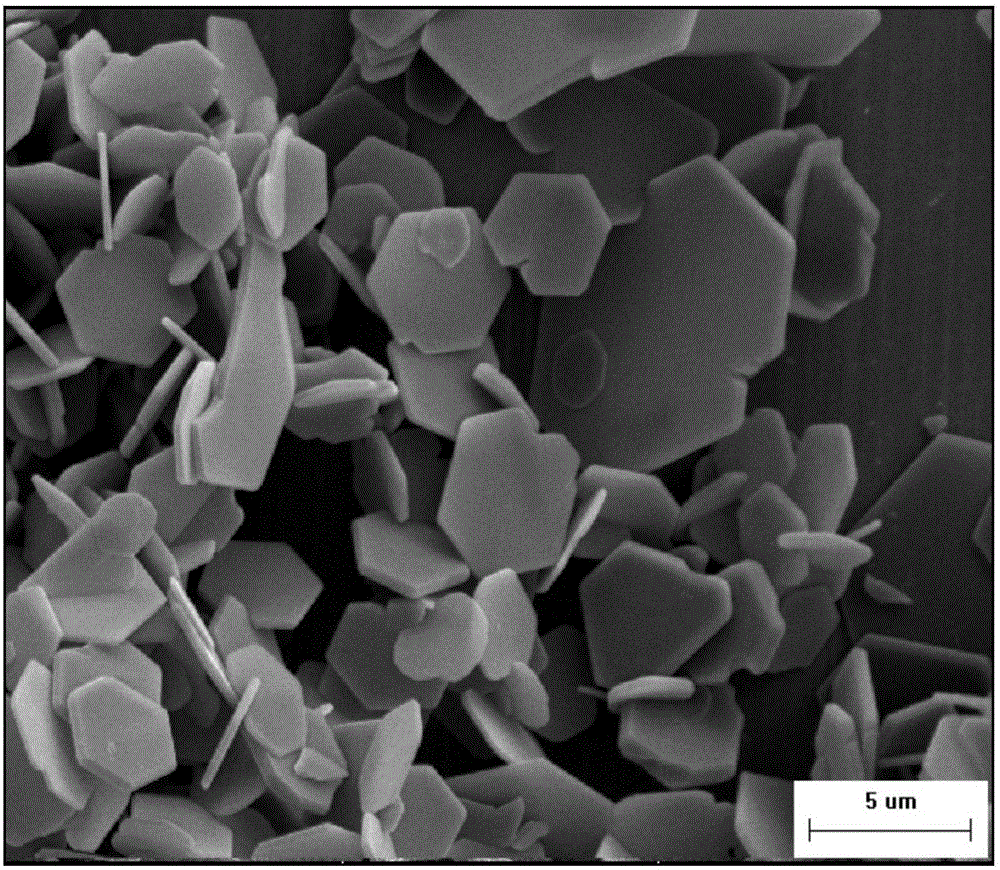

[0038] In the third step, put the aluminum hydroxide gel in an oven and dry it at 100°C for 24 hours. After drying, it is placed in an alumina crucible, calcined in a mu...

Embodiment 2

[0041] In this example, flake α-Al 2 o 3 The amount of seed crystals added was 20% of the mass of the final alumina, and other conditions and methods were the same as in Example 1.

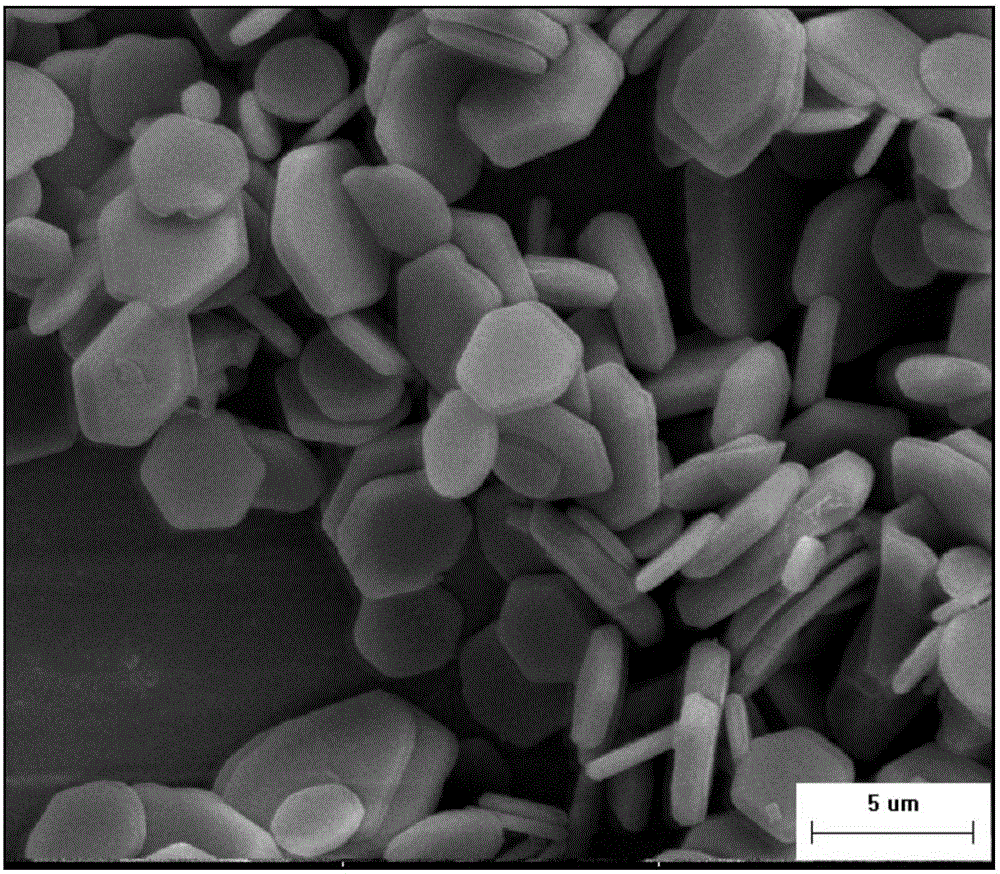

[0042] from SEM figure 2 As can be seen in the flaky α-Al 2 o 3 For the hexagonal scales, no twin nuclei reunion. The flaky α-Al was obtained by analyzing the software Nano Measurer 1.2 2 o 3 The average particle size is 4.69±0.35um. When stirred and dispersed in water, flake α-Al 2 o 3 The powder produces smooth streamlines with strong metallic luster, showing its good dispersibility in water. Discovery of flaky α-Al 2 o 3 The final particle size of the powder and the flake α-Al 2 o 3 The size of the seed crystal is proportional to the size of the flaky α-Al 2 o 3 The cubic root of the seed content is inversely proportional to the relationship; by changing the flake α-Al 2 o 3 The size and content of the seed crystals can well realize the flaky α-Al 2 o 3 Powder particle size ...

Embodiment 3

[0044] In this example, flake α-Al 2 o 3 The amount of seed crystals added was 40% of the mass of the final alumina, and other conditions and methods were the same as in Example 1.

[0045] from SEM image 3 As can be seen in the flaky α-Al 2 o 3 For the hexagonal scales, no twin nuclei reunion. The flaky α-Al was obtained by analyzing the software Nano Measurer 1.2 2 o 3 The average particle size is 3.76±0.22um. When stirred and dispersed in water, flake α-Al 2 o 3 The powder produces smooth streamlines with strong metallic luster, showing its good dispersibility in water. Discovery of flaky α-Al 2 o 3 The final particle size of the powder and the flake α-Al 2 o 3 The size of the seed crystal is proportional to the size of the flaky α-Al 2 o 3 The cubic root of the seed content is inversely proportional to the relationship; by changing the flake α-Al 2 o 3 The size and content of the seed crystals can well realize the flaky α-Al 2 o 3 Powder particle size c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com