High-temperature resistance organic silicon adhesive

A silicone and adhesive technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of insufficient heat resistance in adhesion and mechanical properties, and achieve fast curing speed and use Convenience, simplicity, and efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

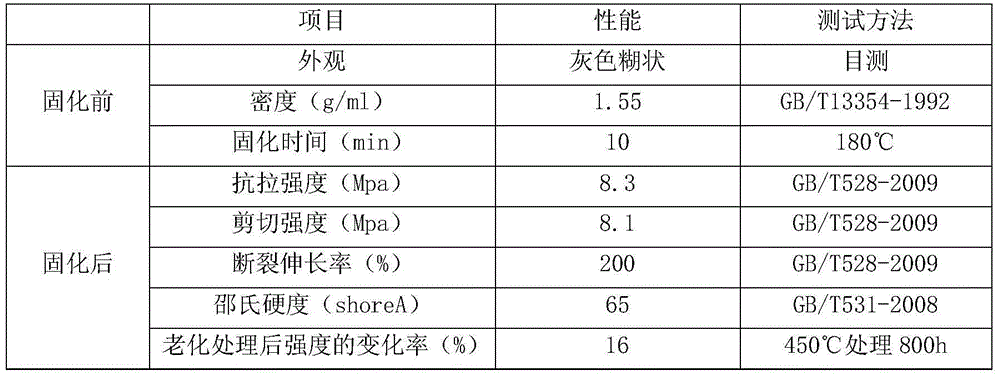

Examples

Embodiment 1

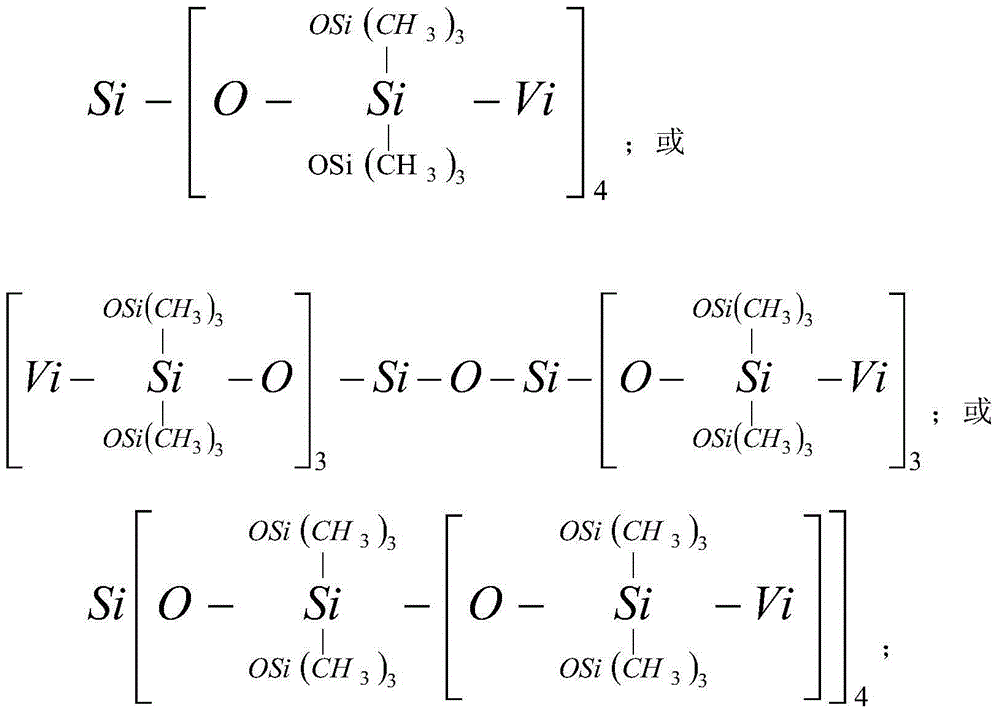

[0023] The vinyl-terminated polyorganosiloxane used in this example is a vinyl-terminated polydimethylsiloxane with a vinyl content of 2.5 wt% and a viscosity of 5000 centipoise; the reinforcing resin used is vinyl triethoxy Polysilane is a body-type vinyl-terminated polydimethylsiloxane with a vinyl content of 0.5 wt% formed by polycondensation of the core molecule with orthosilicate ethyl and ethoxytrimethylsilane, and its structural formula is:

[0024]

[0025] The toughening resin used is a mixture of octavinyl cage silsesquioxane with a vinyl content of 0.15 wt% and trapezoidal silsesquioxane with a vinyl content of 0.15 wt%; the crosslinked resin used is a hydrogen-containing 0.5% polymethylhydrogensiloxane.

[0026] Put 100 parts of vinyl-terminated polyorganosiloxane, 10 parts of reinforcing resin and 10 parts of toughening resin into a dynamic mixer and heat and stir under vacuum for 1 hour. The heating temperature is 110°C, and the vacuum degree is kept below -0....

Embodiment 2

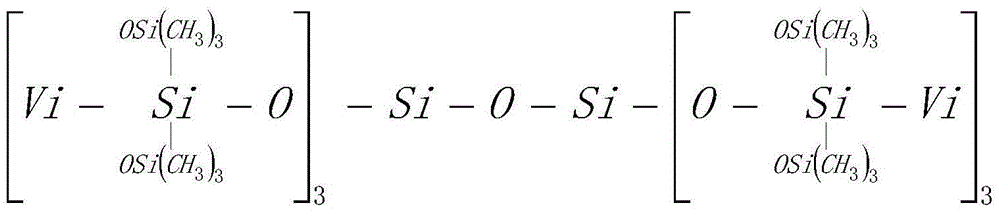

[0032] The vinyl-terminated polyorganosiloxane used in this example is a vinyl-terminated polydimethylsiloxane with a vinyl content of 0.008 wt% and a viscosity of 15,000 centipoise; the reinforcing resin used is vinyl triethoxy Silane is a bulk vinyl-terminated polydimethylsiloxane with a vinyl content of 2.5 wt% formed by polycondensation of the core molecule with orthosilicate ethyl and ethoxytrimethylsilane, and its structural formula is:

[0033]

[0034] a mixture of the two;

[0035]The toughened resin used is a mixture of octavinyl cage silsesquioxane with vinyl content of 0.2wt% and trapezoidal silsesquioxane with vinyl content of 0.2wt%; The resin is polymethylhydrogensiloxane with a hydrogen content of 1.5 wt%.

[0036] Put 100 parts of vinyl-terminated polyorganosiloxane, 30 parts of reinforcing resin and 30 parts of toughening resin into a dynamic mixer, heat and stir in vacuum for 2 hours, the heating temperature is 110 ° C, and the vacuum degree is kept be...

Embodiment 3

[0041] The vinyl-terminated polyorganosiloxane used in this example is vinyl-terminated polydimethylsiloxane with a viscosity of 80,000 centipoise and a vinyl content of 0.008 wt %; the reinforcing resin used is vinyl triethoxy The polydimethylsiloxane with a vinyl content of 2.5% is a bulk vinyl-terminated polydimethylsiloxane formed by polycondensation of polysilane as the core molecule with ethyl orthosilicate and ethoxytrimethylsilane. Its structural formula is:

[0042]

[0043] a mixture of the two;

[0044] The toughened resin used is a mixture of octavinyl cage silsesquioxane with vinyl content of 0.2wt% and trapezoidal silsesquioxane with vinyl content of 0.2wt%; The resin is polymethylhydrogensiloxane with a hydrogen content of 1.5 wt%.

[0045] Put 100 parts of vinyl-terminated polyorganosiloxane, 15 parts of reinforcing resin and 15 parts of toughening resin into a power mixer and heat and stir under vacuum for 2 hours. The heating temperature is 80 ° C, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com