High-performance tracking-resistant silicone rubber and preparation method thereof

A technology of electric leakage tracking and silicone rubber, applied in the fields of silicone rubber insulation materials and polymer insulation materials, can solve the problems of deteriorating processing performance and mechanical properties, damaging the processing performance and mechanical properties of silicone rubber, and complicated processes, so as to improve the resistance to Leakage tracking performance, overcoming poor mechanical properties, easy industrial production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

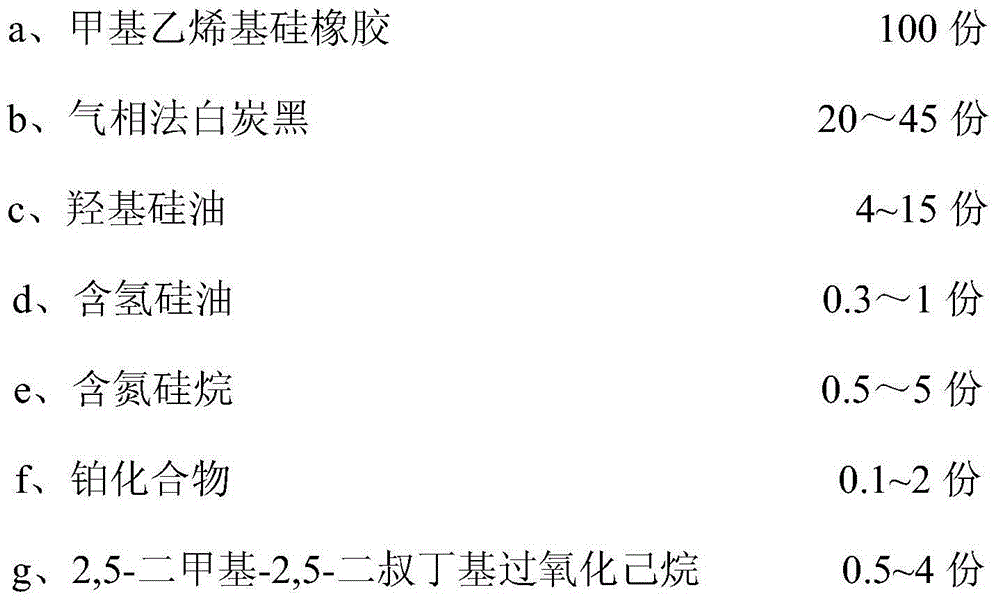

Method used

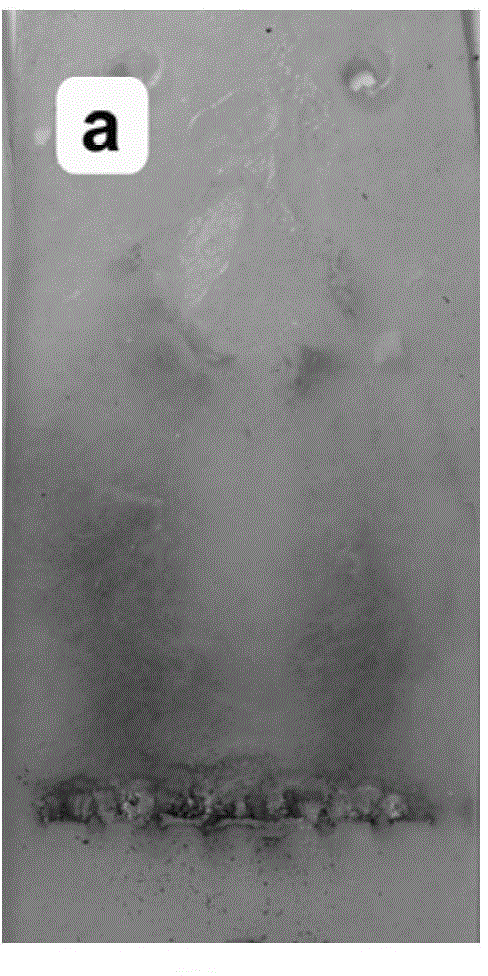

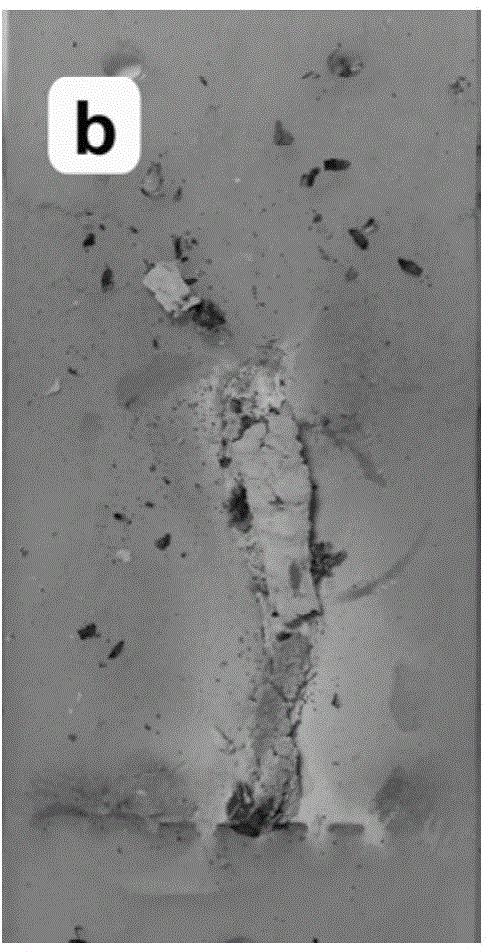

Image

Examples

Embodiment 1

[0033] 90 parts by mass of methyl vinyl silicone rubber (molecular weight 560,000) with 0.05 mol% vinyl content, 10 parts by mass of methyl vinyl silicone rubber (molecular weight 600,000) with 3 mol% vinyl content, 40 parts by mass of gas-phase method white carbon Black (specific surface area 260m 3 / g), 8 parts by mass of hydroxyl silicone oil (hydroxyl content 6wt%) and 0.6 parts by mass hydrogen-containing silicone oil (hydrogen content 1.2wt%) were mixed in a kneader, and kneaded at room temperature for 4h. Then heat to 150°C and continue kneading for 2h, then vacuum knead for 1h, and cool to room temperature to obtain a silicone rubber base rubber.

[0034] Add 2.5 parts by mass of ureapropyltrimethoxysilane (molecular formula: H 2 NCONHCH 2 CH 2 CH 2 Si(OCH 3 ) 3 ), 0.3 parts by mass of divinyltetramethyldisiloxane complex of chloroplatinic acid and 2 parts by mass of 2,5-dimethyl-2,5-di-tert-butylperoxyhexane, mixed evenly Film out later. Vulcanize at 165°C for...

Embodiment 2

[0037] The difference between this example and Example 1 is that 90 parts by mass of methyl vinyl silicone rubber with a vinyl content of 0.05 mol% and 10 parts by mass of a vinyl content of 3 mol% are converted into 50 parts by mass of 0.07 mol% vinyl content ( Molecular weight 600,000) and 50 parts by mass of methyl vinyl silicone rubber with 0.25 mol% vinyl content (molecular weight 600,000), 2.5 parts by mass of ureapropyltrimethoxysilane is converted into 1 part by mass of aminopropyltriethoxysilane (molecular formula: H 2 NCH 2 CH 2 CH 2 Si(OCH 2 CH 3 ) 3 ), the divinyltetramethyldisiloxane complex of 0.3 parts by mass of chloroplatinic acid was converted into 0.3 parts by mass of chloroplatinic acid tetrahydrofuran solution. The properties of the samples are shown in Table 1.

[0038] It can be seen from Table 1 that the silicone rubber of this embodiment can also pass the 1A4.5 level tracking resistance test. It shows that aminopropyltriethoxysilane and chlorop...

Embodiment 3

[0040] The difference between this example and Example 1 is that 90 parts by mass of methyl vinyl silicone rubber with a vinyl content of 0.05 mol% and 10 parts by mass of a vinyl content of 3 mol% are respectively converted into 80 parts by mass of a vinyl content of 0.05 mol% (molecular weight 560,000) and 20 parts by mass of 0.3mol% vinyl content (molecular weight 590,000) of methyl vinyl silicone rubber, 2.5 parts by mass of ureapropyltrimethoxysilane is converted into 2 parts by mass of guanidinepropyltriethoxysilane ( Molecular formula: H 2 NC(=NH)NHCH 2 CH 2 CH 2 Si(OCH 2 CH 3 ) 3 ). The properties of the samples are shown in Table 1.

[0041] It can be seen from Table 1 that the silicone rubber of this embodiment can pass the 1A4.5 level tracking resistance test, indicating that the complexation of guanidinyl triethoxysilane and chloroplatinic acid with divinyltetramethyldisiloxane At the same time, two kinds of silicone rubbers with different vinyl content can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com