Method used for purifying sodium tungstate solution

A sodium tungstate solution technology, applied in the field of metallurgy, can solve the problems of excessive ammonium paratungstate cation elements, affecting tungsten adsorption capacity, poor comprehensive impurity removal effect, etc., and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0037] According to a specific embodiment of the present invention, the method includes the following steps: adding waste tungsten oxide, waste ammonium paratungstate, tungstic acid and waste cemented carbide into the sodium tungstate solution at 50-100° C. at least one of the sodium tungstate solution, and keep stirring to adjust the pH value of the sodium tungstate solution to 8.0-10.0, so as to precipitate silicon to obtain the first sodium tungstate mixed solution containing the silicon precipitation; to the first sodium tungstate solution; adding magnesium salt to the sodium tungstate mixed solution to obtain the second sodium tungstate mixed solution; heating the second sodium tungstate mixed solution to a temperature of not lower than 50°C, and continuously stirring the second sodium tungstate mixed solution , and keep the temperature for 1-3 hours, so as to obtain the third sodium tungstate mixed solution containing the precipitate; and filter the third sodium tungstate...

Embodiment 1

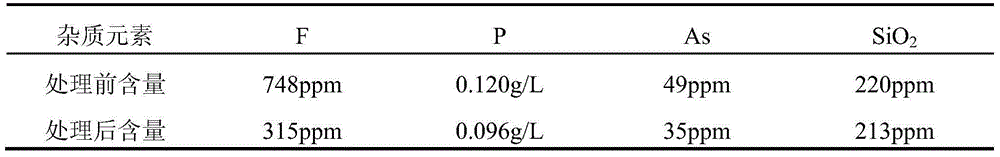

[0042] For containing WO 3 232.7g / L, F 748ppm, P 0.120g / L, SiO 2 The method that 220ppm of sodium tungstate feed liquid is purified is as follows:

[0043] 1. Take 200ml of sodium tungstate feed solution, heat it to about 80°C, and add tungstic acid under stirring conditions. When pH=8~9, stop feeding.

[0044] 2. Add 2.4 g of analytically pure basic magnesium carbonate powder, stir continuously, and keep the temperature for 3 hours to obtain a mixed solution containing precipitates.

[0045] 3. Filter the mixed solution obtained in the previous step to obtain filtrate and residue.

[0046] 4. Determine the composition of the filtrate and slag, as follows:

[0047] Filtrate composition

[0048]

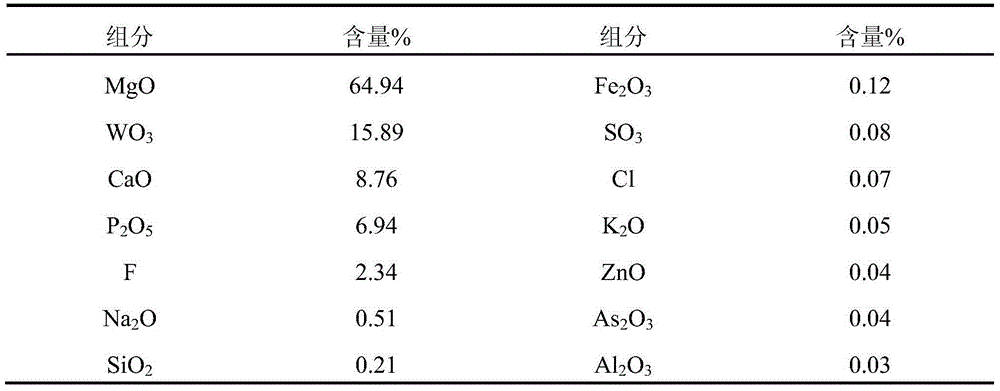

[0049] Composition of slag

[0050]

[0051] It can be found from the above table that the sodium tungstate feed liquid obtained by the purification process of the method of the present invention contains impurity elements F, P, As and SiO. 2 After sufficient precipitation...

Embodiment 2

[0053] For containing WO 3 232.7g / L, F 748ppm, P 0.120g / L, SiO 2 The method that 220ppm of sodium tungstate feed liquid is purified is as follows:

[0054] 1. Take 200ml of sodium tungstate feed solution, heat it to about 80°C, and add tungsten oxide under stirring conditions. When pH=8~9, stop feeding.

[0055] 2. Add 2g of magnesium oxide, keep stirring for 3h, to obtain a mixed solution containing precipitation

[0056] 3. Filter the mixed solution obtained in the previous step to obtain filtrate and residue.

[0057] 4. Determine the composition of the filtrate and slag, as follows:

[0058] Filtrate composition

[0059]

[0060] Composition of slag

[0061]

[0062] From the above table, it can be found that the sodium tungstate feed liquid obtained through the purification treatment of the method of the present invention, the impurity elements F, P, As and Si are fully precipitated, the content of the above-mentioned impurity elements in the filtrate is signif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com