Golden finger processing method characterized by no lead wire residues

A processing method, gold finger technology, applied in the processing steps sequence, electrical connection formation of printed components, electrical components, etc., can solve problems such as reducing production costs, achieve the effects of reducing production costs, improving yield, and reducing refills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

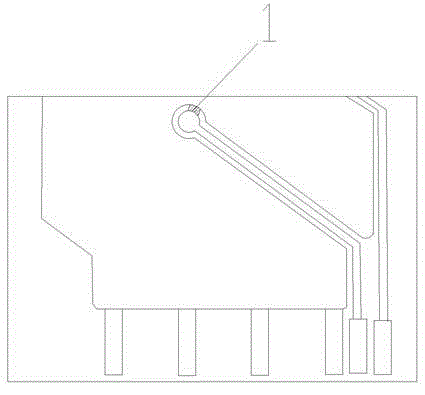

[0030] Such as figure 1 As shown, a gold finger treatment method without lead wire residue comprises the following steps:

[0031] S1. Fabrication, pressing, and drilling of the inner circuit board, and electroplating the entire surface of the outer circuit board to make the outer circuit board.

[0032] S2. The first outer graphics transfer.

[0033] According to the distribution of the golden finger part of the outer circuit board, select the network connection point suitable for the golden finger part. Such as figure 1 As shown, when the network connection point 1 of the golden finger part of the outer circuit board is determined to be between the PAD hole and the copper skin, make a film picture A, and make a graphic of the network connection point in the film picture A. When making the film picture A, the circuit graphics, gold finger parts and network connection points connecting each gold finger are all light-transmitting parts, and other parts are opaque parts. Pas...

Embodiment 2

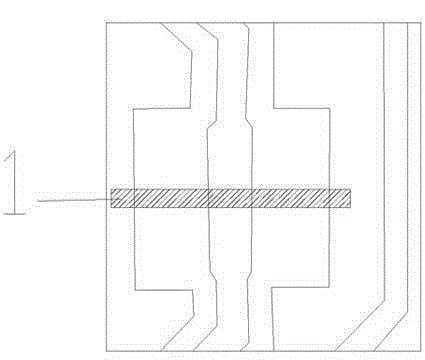

[0044] Such as figure 2 As shown, a gold finger treatment method without lead wire residue comprises the following steps:

[0045] S1. Fabrication, pressing, and drilling of the inner circuit board, and electroplating the entire surface of the outer circuit board to make the outer circuit board.

[0046] S2. The first outer graphics transfer.

[0047] According to the distribution of the golden finger part of the outer circuit board, select the network connection point suitable for the golden finger part. Such as figure 2 As shown, when it is determined that the network connection point 1 of the golden finger part of the outer circuit board is between the patches, make a film picture A, and make a graphic of the network connection point in the film picture A. When making the film picture A, the circuit graphics, gold finger parts and network connection points connecting each gold finger are all light-transmitting parts, and other parts are opaque parts. Paste a layer of ...

Embodiment 3

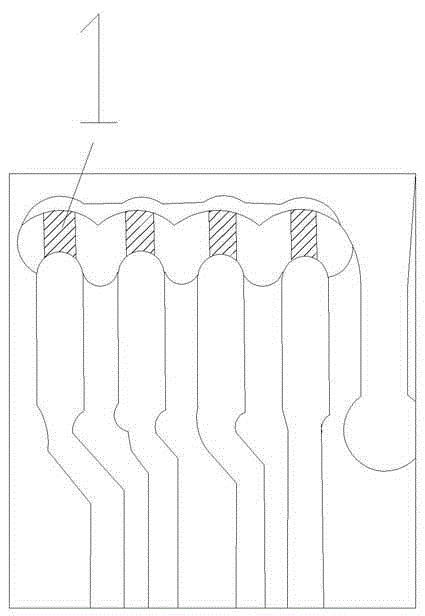

[0058] Such as image 3 As shown, a gold finger treatment method without lead wire residue comprises the following steps:

[0059] S1. Fabrication, pressing, and drilling of the inner circuit board, and electroplating the entire surface of the outer circuit board to make the outer circuit board.

[0060] S2. The first outer graphics transfer.

[0061] According to the distribution of the golden finger part of the outer circuit board, select the network connection point suitable for the golden finger part. Such as image 3 As shown, when it is determined that the network connection point 1 of the gold finger part of the outer circuit board is between the IC and the copper skin, make a film picture A, and make a graphic of the network connection point in the film picture A. When making the film picture A, the circuit graphics, gold finger parts and network connection points connecting each gold finger are all light-transmitting parts, and other parts are opaque parts. Paste ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com