Surface modification method of medical magnesium alloy

A surface modification and magnesium alloy technology, which is applied in the field of surface modification of medical magnesium alloys, can solve the problems of easy falling off, small binding force, and high degradation rate of magnesium alloys, and achieve increased surface roughness and good biocompatibility properties, improving binding strength and biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0017] Embodiment 1: The surface modification method of the medical magnesium alloy of the present embodiment is realized according to the following steps:

[0018] 1. Use metallographic sandpaper to polish the medical magnesium alloy material, then place it in absolute ethanol for ultrasonic cleaning at room temperature for 4-6 minutes, then use deionized water for ultrasonic cleaning at room temperature for 5-8 minutes, take it out and air dry it naturally to obtain The cleaned medical magnesium alloy material;

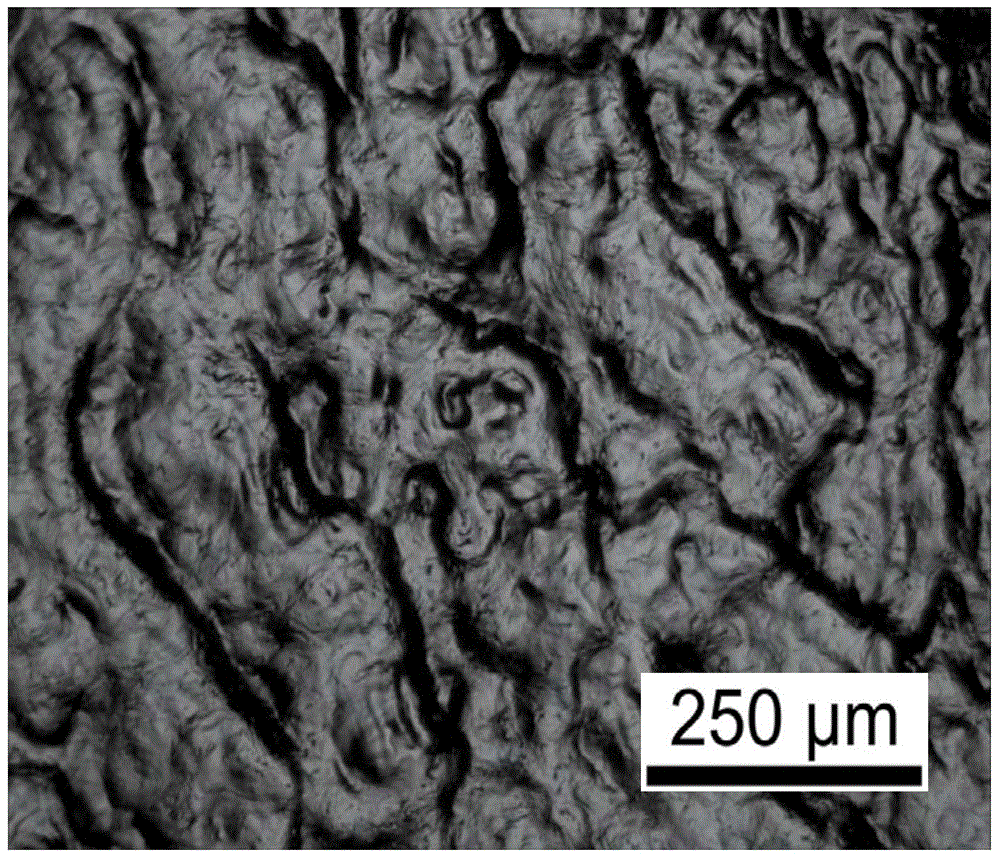

[0019] 2. Put the cleaned medical magnesium alloy material obtained in step 1 into the vacuum chamber of the high-current pulsed electron beam device, pass argon into the vacuum chamber after evacuation, open the electron gun, and control the acceleration voltage of the electron gun to be 10~20kV, The pulse width is 2-5 μs, the irradiation interval time is 10-15 s, and the irradiation times are 5-15 times to obtain a medical magnesium alloy material with a remelting...

specific Embodiment approach 2

[0022] Specific embodiment 2: The difference between this embodiment and the specific embodiment 1 is that in step 1, 320#, 600# and 1200# metallographic sandpapers are sequentially used to polish the medical magnesium alloy material. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Embodiment 3: This embodiment is different from Embodiment 1 or 2 in that step 2 is evacuated to 1×10 -3 ~5×10 -3 After Pa, argon gas was introduced into the vacuum chamber, and the air pressure was maintained at 0.04-0.06Pa. Other steps and parameters are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com