Method for recovering waste heat of melting slag

A waste heat recovery and molten slag technology, applied in the field of waste heat recovery, can solve the problems of large power consumption, low heat recovery efficiency, and high difficulty in heat recovery, and achieve the effects of small footprint, high pressure and high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

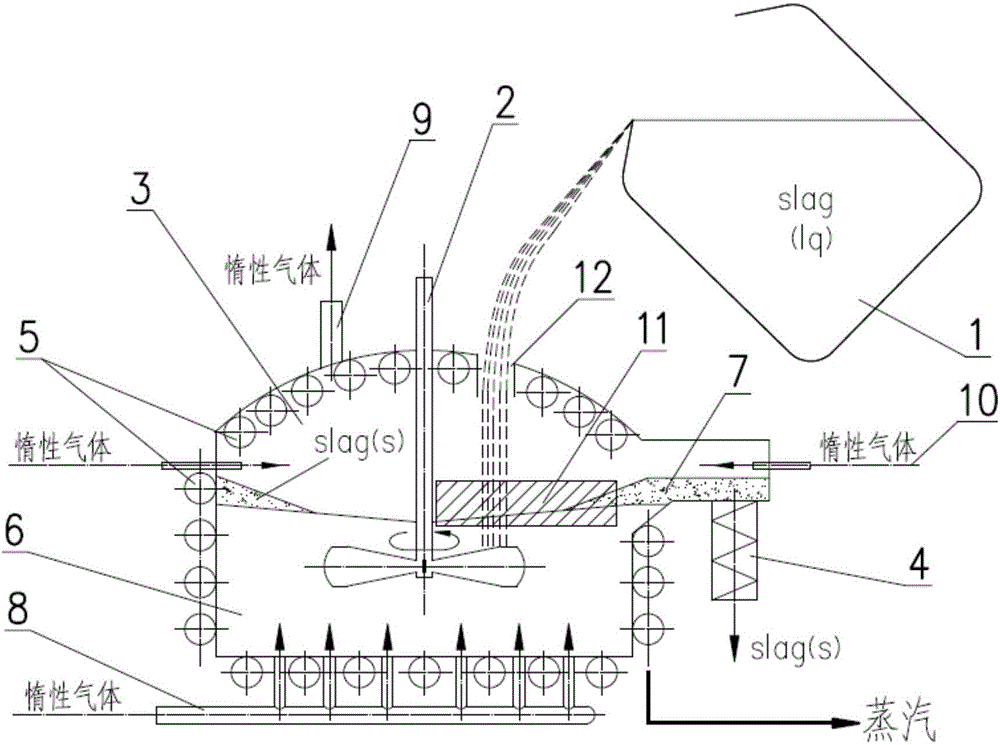

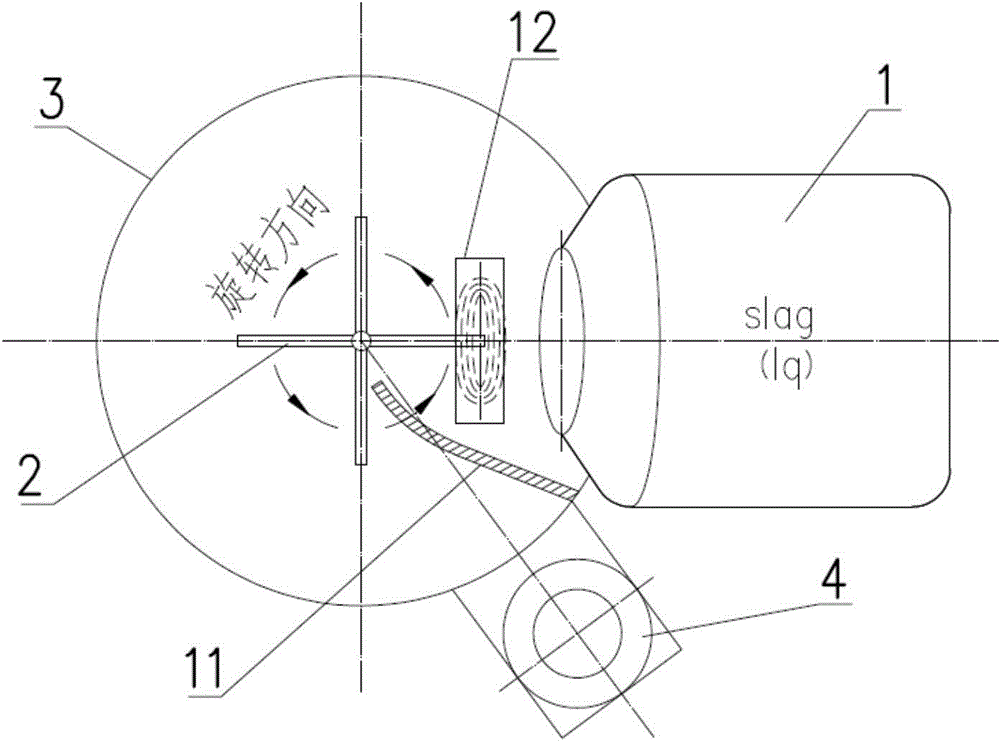

[0028] The invention proposes a method for recovering waste heat of molten slag.

[0029] In this preferred embodiment, the method for recovering waste heat from molten slag comprises the following steps:

[0030] The high-temperature molten slag is injected into the heat recovery tank, and the molten slag is rapidly cooled into solid slag while being mixed with the low-melting-point molten metal in the heat-recovery tank, wherein the low-melting-point metal is a metal or alloy with a melting point of 500°C or below. The molten slag is high-temperature molten slag produced by ferrous metallurgy or nonferrous metallurgy;

[0031] The molten slag and the low-melting-point molten metal realize rapid heat transfer, and at the same time, the solid slag floats up to form a scum layer, and the scum is discharged intermitten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com