Manufacturing method of composite oxide ceramic chopper

A composite oxide and manufacturing method technology, which is applied in the field of special ceramic molding, can solve problems such as difficult manufacturing of ceramic choppers, and achieve the effects of less green body molding defects, easy industrial production, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for manufacturing a composite oxide ceramic chopper, comprising the steps of:

[0021] Step 1: Dissolve 0.05g of acrylamide (AM), 0.01g of N,N'-methylenebisacrylamide (MBAM) and 0.03g of dispersant in 16mL of distilled water to prepare a premix solution, and adjust the pH value to 9.5~ 11;

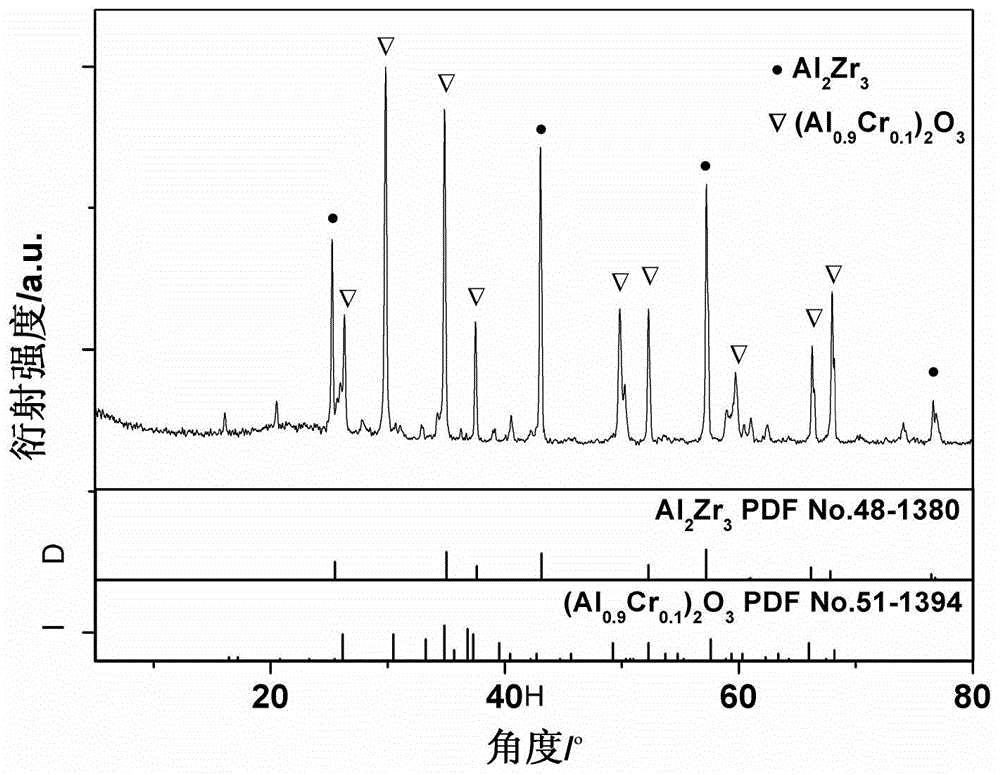

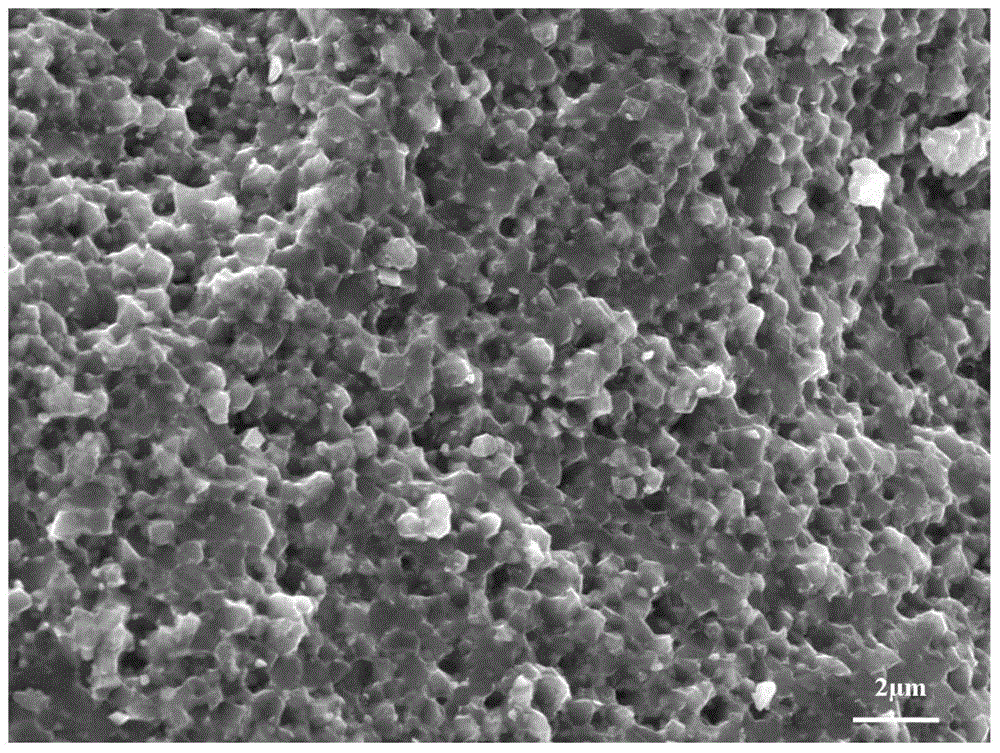

[0022] Step 2, adding 30g of alumina ceramic powder, 10g of chromium oxide, and 15g of zirconia to the premixed solution, and then adding zirconia balls and ball milling for 24-48 hours;

[0023] Step 3, then add 0.3g ammonium persulfate (APS) and 0.3g n-octanol, and ball mill evenly to obtain slurry;

[0024] Step 4, pour the obtained slurry into the mold, cover the mold lid, and let it stand at room temperature for 5 to 15 minutes to polymerize the organic monomers in the slurry, that is, the gelation process. During this process, the organic monomers The body and the cross-linking agent work together to form a strong three-dimensional network structure, so that the alu...

Embodiment 2

[0028] A method for manufacturing a composite oxide ceramic chopper, comprising the steps of:

[0029] Step 1: Dissolve 0.2g of acrylamide (AM), 0.3g of N,N'-methylenebisacrylamide (MBAM) and 1g of dispersant in 32mL of distilled water to prepare a premix, and adjust the pH to 9.5-11 ;

[0030] Step 2, adding 45g of alumina ceramic powder, 13g of chromium oxide, and 20g of zirconia to the premixed solution, and then adding zirconia balls and ball milling for 24 to 48 hours;

[0031] Step 3, then add 3g ammonium persulfate (APS) and 3g n-octanol, and ball mill evenly to obtain slurry;

[0032] Step 4, pour the obtained slurry into the mold, cover the mold lid, and let it stand at room temperature for 5 to 15 minutes to polymerize the organic monomers in the slurry, that is, the gelation process. During this process, the organic monomers The body and the cross-linking agent work together to form a strong three-dimensional network structure, so that the alumina particles are so...

Embodiment 3

[0035] A method for manufacturing a composite oxide ceramic chopper, comprising the steps of:

[0036] Step 1: Dissolve 0.01g of acrylamide (AM), 0.002g of N,N'-methylenebisacrylamide (MBAM) and 0.006g of dispersant in 23mL of distilled water to prepare a premix solution, and adjust the pH value to 9.5~ 11;

[0037] Step 2, adding 40g of alumina ceramic powder, 10g of chromium oxide, and 25g of zirconia to the premixed liquid, and then adding zirconia balls and ball milling for 24-48 hours;

[0038] Step 3, then add 5g ammonium persulfate (APS) and 4g n-octanol, and ball mill evenly to obtain slurry;

[0039] Step 4, pour the obtained slurry into the mold, cover the mold lid, and let it stand at room temperature for 5 to 15 minutes to polymerize the organic monomers in the slurry, that is, the gelation process. During this process, the organic monomers The body and the cross-linking agent work together to form a strong three-dimensional network structure, so that the alumina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com