Preparation method of fine-grained CuCr alloy

A fine-grained and alloyed technology, applied in the field of preparation of fine-grained CuCr alloys, to achieve the effects of narrow particle size distribution, shortened time and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The weight percentage of preparation chromium is the CuCr alloy of 50%, and process step is as follows:

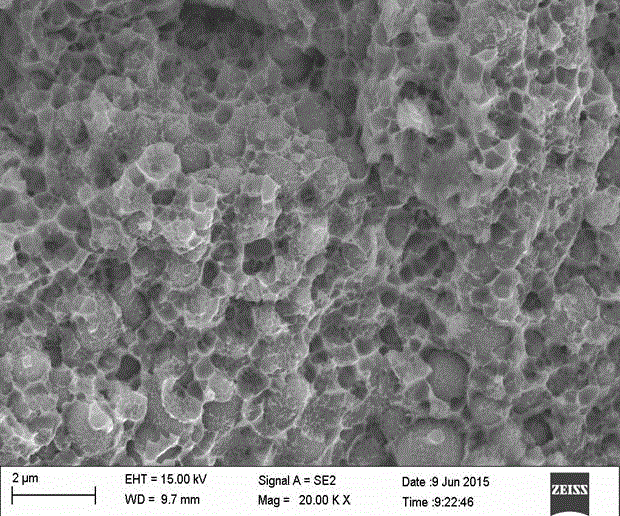

[0032] (1) Preparation of fine-grained CuCr alloy material: Put the oxygen-free copper block and the chromium block into the crucible with a nozzle at the bottom according to the mass ratio of 1:1, induction heating to melt and dissolve the copper block and the chromium block, and pressurize the argon gas The molten liquid is sprayed out and passed through the copper roll to quickly cool and throw the belt, wherein the copper roll speed is 1000r / min, and a thin strip-shaped fine-grained CuCr alloy material is obtained; figure 1 As shown, the particle size of chromium particles is 0.1~1μm;

[0033] (2) Refining fine-grained CuCr alloy material: The thin-sheet strip-shaped fine-grained CuCr alloy material is ball-milled with a high-energy ball mill under the protection of argon, and the mass ratio of the ball milling ball to the alloy material is 10:1 to obtain a unif...

Embodiment 2

[0038] The weight percentage of preparation chromium is the CuCr alloy of 25%, and process step is as follows:

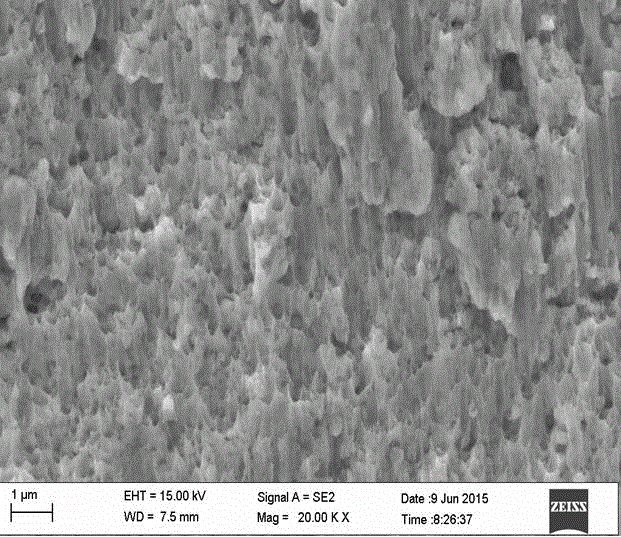

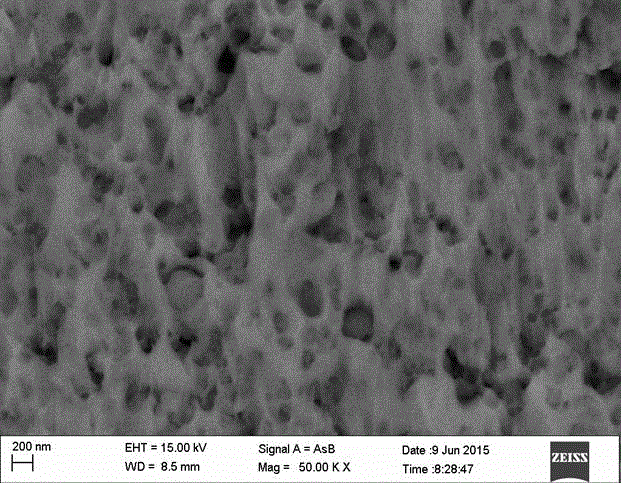

[0039] (1) Preparation of fine-grained CuCr alloy material: Put the oxygen-free copper block and the chromium block into the crucible with a nozzle at the bottom according to the mass ratio of 3:1, and induce the melting and mutual dissolution of the copper block and the chromium block. The molten liquid is sprayed out and passed through the copper roll to quickly cool and throw the belt, wherein the copper roll speed is 1000r / min, and a thin strip-shaped fine-grained CuCr alloy material is obtained; figure 2 , image 3 As shown, the chromium particle size is 0.1~1μm

[0040] (2) Refined fine-grained CuCr alloy material: The thin-sheet strip-shaped fine-grained CuCr alloy material is ball-milled with a high-energy ball mill under the protection of argon, and the mass ratio of the ball milling ball to the alloy material is 3:1 to obtain a uniform particle size dist...

Embodiment 3

[0045] The weight percentage of preparation chromium is the CuCr alloy of 50%, and process step is as follows:

[0046] (1) Preparation of fine-grained CuCr alloy material: Put the oxygen-free copper block and the chromium block into the crucible with a nozzle at the bottom according to the mass ratio of 1:1, induction heating to melt and dissolve the copper block and the chromium block, and pressurize the argon gas The molten liquid is sprayed and sprayed through a water-cooled rotating disk for centrifugal atomization, wherein the rotating disk rotates at a speed of 7000r / min to obtain granular fine-grained CuCr alloy materials;

[0047] (2) Refining fine-grained CuCr alloy material: The thin-sheet strip-shaped fine-grained CuCr alloy material is ball-milled with a high-energy ball mill under the protection of argon, and the mass ratio of the ball milling ball to the alloy material is 10:1 to obtain a uniform particle size distribution. fine-grain composite CuCr alloy powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com