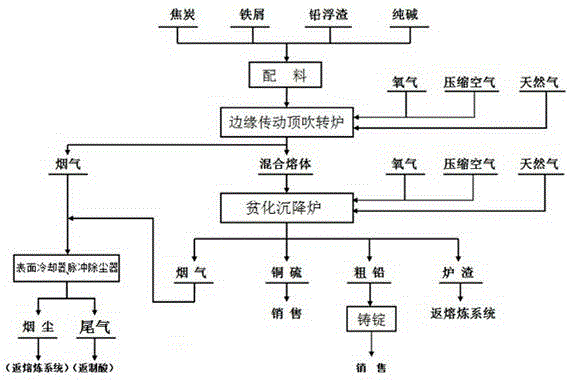

Edge transmission top-blown converter and depleted sedimentation furnace combined lead dross treatment method

A top-blown converter and combined processing technology, applied in the field of metallurgy, can solve the problems of difficult liquid-solid control, large power consumption, troublesome liquid-solid separation, etc., and achieve the effects of reducing the amount of smoke and dust circulation, high degree of automation, and wide use of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Select the model as 1m 3 The edge-driven top-blown converter and the 3.5-square-meter depleted settling furnace are debugged according to the following technical parameters: the oxygen flow rate in the edge-driven top-blown converter is 100m 3 / h, compressed air flow rate 100m 3 / h, natural gas flow 60m 3 / h; Oxygen flow rate in the depleted settling furnace is 60m 3 / h, compressed air flow 80m 3 / h, natural gas flow rate 40m 3 / h;

[0030] After commissioning, follow the steps below to deal with lead scum:

[0031] In terms of mass percentage, 88% of lead scum, 5% of coke, 2% of iron filings, and 5% of soda ash are uniformly mixed through a boat-type feeder, and the lead scum mixture is continuously and evenly added to the edge-driven top-blown converter. Feeding is carried out at 10 tons per hour, and the feeding operation of 5 tons is completed.

[0032] After the feeding operation is completed, keep the temperature of the edge-driven top-blown converter at 10...

Embodiment 2

[0036] Select the model as 1m 3 The edge-driven top-blown converter and the 3.5-square-meter depleted settling furnace are debugged according to the following technical parameters: the oxygen flow rate in the edge-driven top-blown converter is 90m 3 / h, compressed air flow rate 100m 3 / h, natural gas flow 55m 3 / h; Oxygen flow rate in the depleted settling furnace is 60m 3 / h, compressed air flow 60m 3 / h, natural gas flow rate 40m 3 / h;

[0037] After commissioning, follow the steps below to deal with lead scum:

[0038] In terms of mass percentage, 89% of lead scum, 4% of coke, 2% of iron filings, and 5% of soda ash are uniformly mixed through a boat-shaped feeder, and the lead scum mixture is continuously and uniformly added to the edge-driven top-blown converter. Feeding is carried out at 10 tons per hour, and the feeding operation of 6 tons is completed.

[0039] After the feeding operation is completed, keep the temperature of the edge-driven top-blown converter a...

Embodiment 3

[0043] Select the model as 1m 3 The edge-driven top-blown converter and the 3.5-square-meter depleted settling furnace are debugged according to the following technical parameters: the oxygen flow rate in the edge-driven top-blown converter is 120m 3 / h, compressed air flow 90m 3 / h, natural gas flow rate 70m 3 / h; Oxygen flow rate in the depleted settling furnace is 70m 3 / h, compressed air flow 50m 3 / h, natural gas flow rate 50m 3 / h;

[0044] After commissioning, follow the steps below to deal with lead scum:

[0045] In terms of mass percentage, 88% of lead scum, 5% of coke, 2% of iron filings, and 5% of soda ash are uniformly mixed through a boat-type feeder, and the lead scum mixture is continuously and evenly added to the edge-driven top-blown converter. Feeding is carried out at 10 tons per hour, and the feeding operation of 5 tons is completed.

[0046] After completing the feeding operation, keep the temperature of the edge-driven top-blown converter at 1000-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com